A method of using melamine waste to carry out flue gas denitrification

A technology of melamine and waste, applied in the field of SNCR flue gas denitrification and flue gas denitrification, can solve the problems of high product price, high cost of denitrification, complicated process, etc., and achieve the effect of low economic benefit, simple denitrification process and simplified treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Combine melamine waste with NO in flue gas X The mass ratio is 1.01 sprayed into the reactor, the oxygen concentration in the flue gas is 3%, the temperature is controlled at 950°C, and the residence time is controlled at 1.2s. After the reaction, the flue gas is passed into the flue gas analyzer to analyze the NO in the flue gas before and after the reaction. X Concentration, the denitrification rate is 82.32%. The denitrification rate of the existing SNCR technology is mostly lower than 80%. It can be seen that the method adopted in this example can effectively improve the denitrification efficiency of flue gas.

Embodiment 2

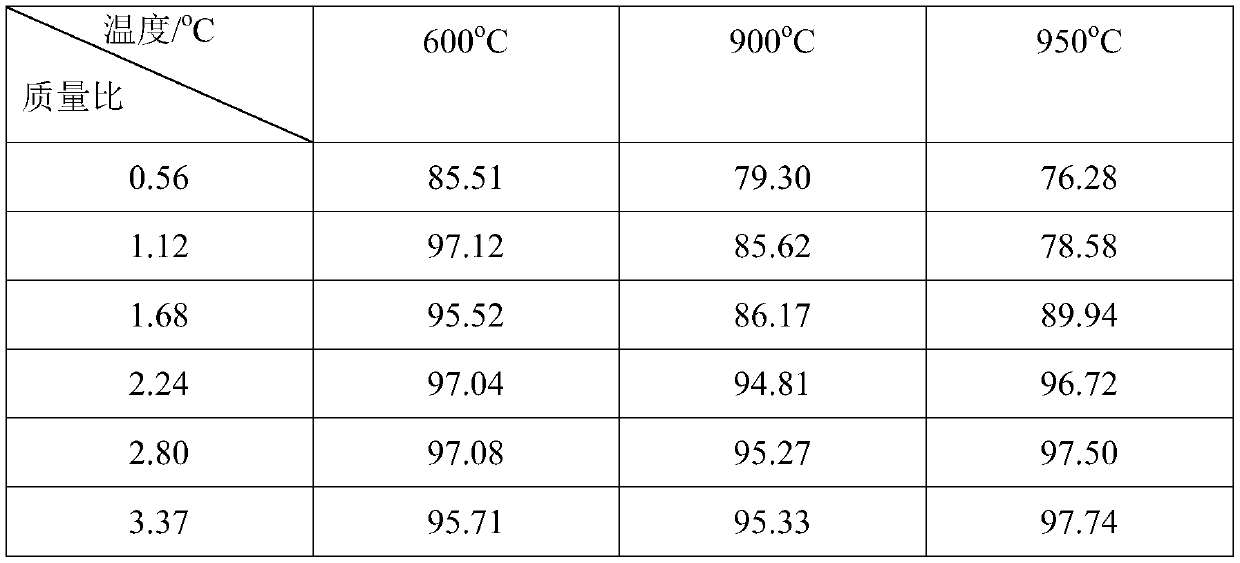

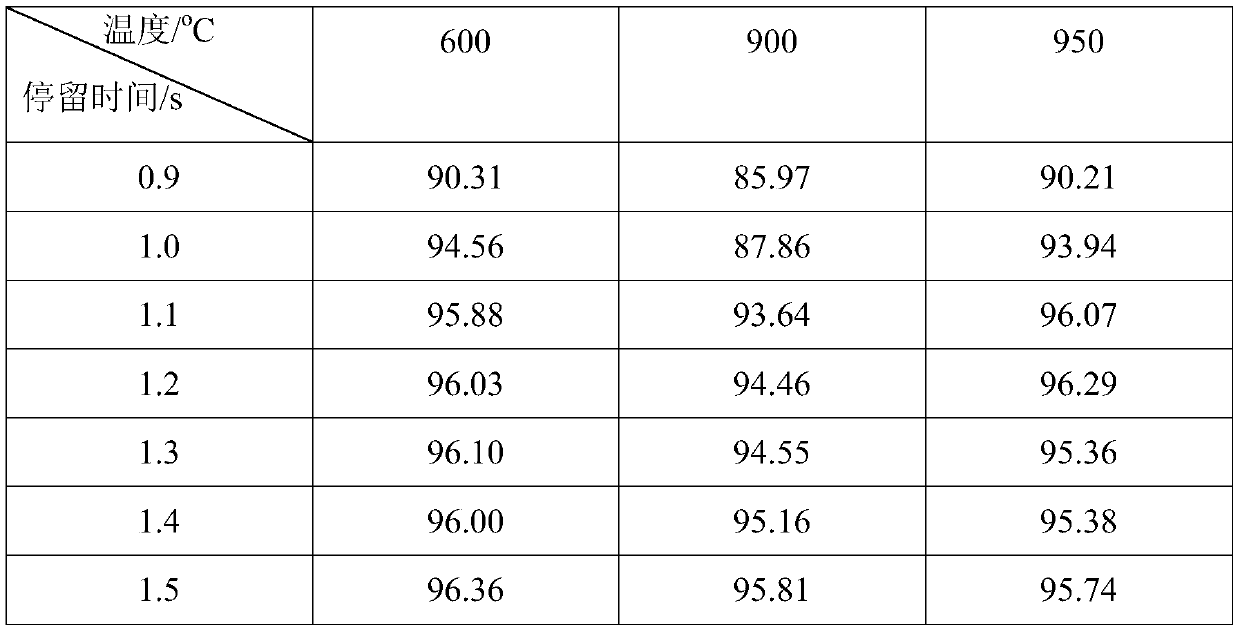

[0036] According to the melamine waste and the NO in flue gas X The mass ratio of 2.24 is sprayed into the reactor, the oxygen concentration in the flue gas is 3%, the temperature is controlled at six temperature points of 600°C, 700°C, 800°C, 900°C, 1000°C, and 1100°C, and the residence time is controlled at 1.2s After the reaction, the flue gas is passed into the flue gas analyzer to analyze the NO in the flue gas before and after the reaction X concentration, the resulting flue gas denitrification rate is shown in Table 1:

[0037] Table 1 The denitrification rate of melamine waste flue gas at different temperatures

[0038] temperature / ℃ 600 700 800 900 1000 1100 Denitrification rate / % 95.05 96.07 92.44 94.51 93.19 93.25

[0039] It can be seen from the experimental data that compared with the existing technology, the method adopted in this embodiment can greatly improve the flue gas denitrification efficiency of the SNCR technology.

Embodiment 3

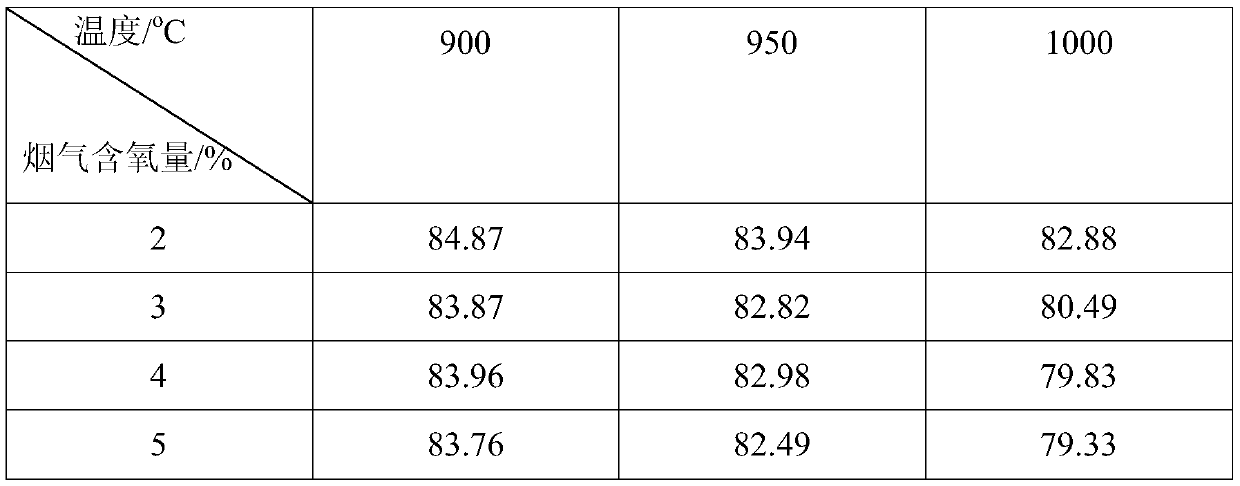

[0041] According to the melamine waste and the NO in flue gas X The mass ratio of 1.402 is sprayed into the reactor, the oxygen concentration in the flue gas is controlled at 2%, 3%, 4%, and 5%, the temperature is controlled at three temperature points of 900°C, 950°C, and 1000°C, and the residence time is controlled at 1.2s, after the reaction, the flue gas is passed into the flue gas analyzer, and the NO in the flue gas before and after the reaction is analyzed X concentration, the resulting flue gas denitrification rate is shown in Table 2:

[0042] Table 2 The denitrification rate of melamine waste flue gas under different flue gas oxygen concentrations at 900°C, 950°C, and 1000°C

[0043]

[0044] It can be seen from the experimental data that compared with the existing technology, the method adopted in this embodiment can greatly improve the flue gas denitrification efficiency of the SNCR technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com