Preparation method of sealwort and coix seed health care liquor with immunity enhancing function

A technology for enhancing immunity and health-care wine, which is applied in the field of wine making, and can solve the problems of low utilization rate of raw materials, a large amount of residue, cumbersome process, etc., and achieve the effects of improving the utilization rate of raw materials, improving the effect of saccharification and liquefaction, and enhancing the fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

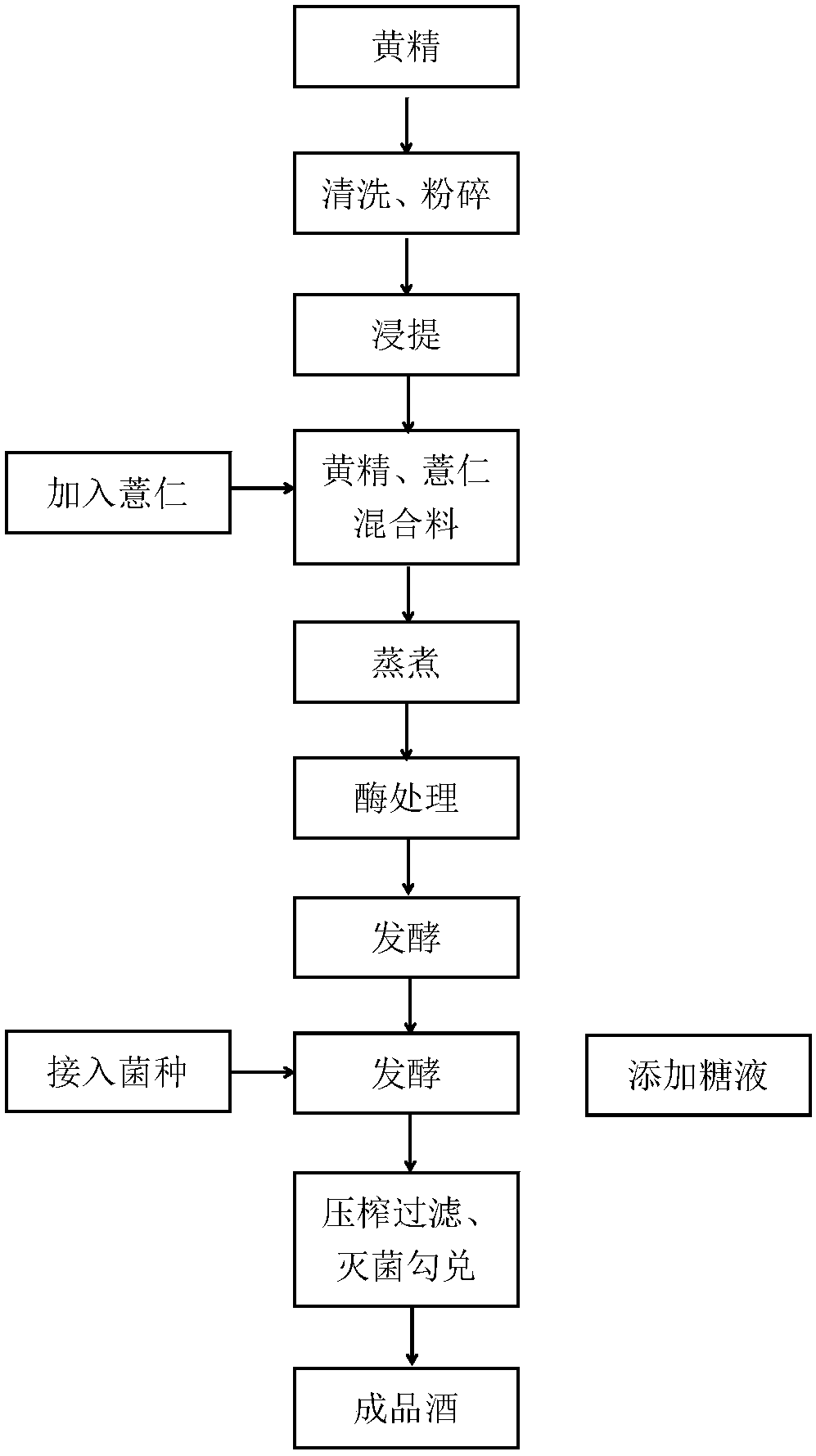

Method used

Image

Examples

Embodiment 1

[0038] The preparation method that embodiment 1 adopts is as follows:

[0039](1) Grind Polygonatum into powder, add 5 times of water, stir evenly, add 100U / g cellulase, extract at 52°C for 80min to obtain the mixture of Polygonatum extract; add barley at a mass ratio of 1:1 powder, steamed for 20min, then adjusted the temperature of the mixed material to 85°C, adjusted the pH to 5.5 with alkali / acid solution, added 120U / g liquefaction enzyme and liquefied at 95°C for 80min; in the next step, lowered the temperature to 58°C, added Glucoamylase, the dosage is 120U / g, and the treatment time is 100min, finally obtain the saccharification solution of sealwort barley;

[0040] (2) Active dry yeast is activated for 30 minutes at 37° C. in an aqueous solution containing 2% sugar;

[0041] (3) Inoculate yeast and Rhizopus oryzae when the product temperature of the material is reduced to 30°C, the inoculation amount of Saccharomyces cerevisiae is 0.4%, the inoculum amount of Aroma Yea...

Embodiment 2

[0045] The preparation method that embodiment 2 adopts is as follows:

[0046] (1) Grind Rhizoma Polygonatum into powder, add 4 times of water, stir well, add 80U / g cellulase, extract at 55°C for 60min to obtain a mixture of Rhizoma Rhizoma Polygonatum extract; add barley at a mass ratio of 1:1 powder, steamed for 20min, then adjusted the temperature of the mixed material to 90°C, adjusted the pH to 5.5 with alkali / acid solution, added 100U / g liquefaction enzyme and liquefied at 90°C for 60min; in the next step, lowered the temperature to 60°C, added The dosage of glucoamylase is 120U / g, and the treatment time is 90min, finally obtain the saccharification solution of sealwort barley;

[0047] (2) Active dry yeast is activated for 20 minutes at 37° C. in an aqueous solution containing 2% sugar;

[0048] (3) Inoculate yeast and Rhizopus oryzae when the product temperature of the material is reduced to 30°C, the inoculation amount of Saccharomyces cerevisiae is 0.3%, the inoculu...

Embodiment 3

[0052] The preparation method that embodiment 3 adopts is as follows:

[0053] (1) Grind Rhizoma Polygonatum into powder, add 5 times of water, stir well, add 50U / g cellulase, extract at 45°C for 75min to obtain a mixture of Rhizoma Rhizoma Polygonatum extract; add barley at a mass ratio of 1:1 Powder, cook for 15 minutes, then adjust the temperature of the mixture to 95°C, adjust the pH to 6.0 with alkali / acid solution, add 80U / g liquefying enzyme and liquefy at 95°C for 70min; The dosage of glucoamylase is 150U / g, and the treatment time is 80min, finally obtain the saccharification solution of sealwort barley;

[0054] (2) Active dry yeast is activated for 30 minutes at 37° C. in an aqueous solution containing 2% sugar;

[0055] (3) Inoculate yeast and Rhizopus oryzae when the product temperature of the material is reduced to 26°C, the inoculation amount of Saccharomyces cerevisiae is 0.2%, the inoculum amount of Aroma Yeast is 0.3%, and Rhizopus oryzae is inoculated with m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com