PET film with high extinction and uvioresistant performances and its preparation method

A high-performance, UV-resistant technology, applied in the field of functional films, can solve the problems of three-dimensional structure damage, affecting the application prospects of PS hollow microspheres, and the inability to apply melt processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for extinction and anti-ultraviolet high-performance PET film, the steps are as follows:

[0058] (1) Preparation of core-shell structure organic / inorganic composite hollow porous microspheres:

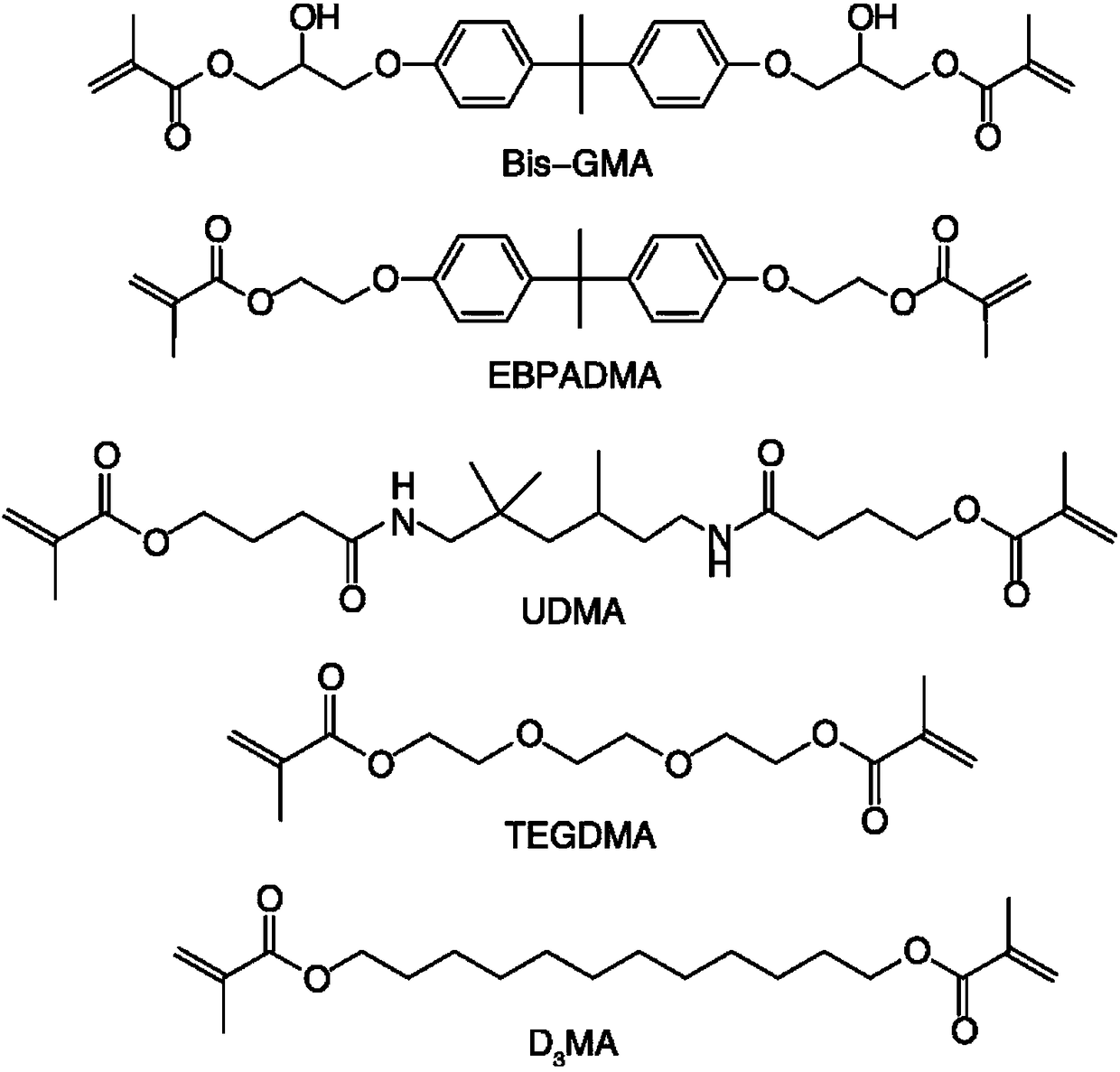

[0059] 1) Dissolving styrene, Bis-GMA, DMPOH and phenyl salicylic acid in DMF to obtain an electrospray solution, wherein in the electrospray solution, Bis-GMA accounts for 5wt% of the total amount of styrene and Bis-GMA, DMPOH Accounting for 1.0wt% of the total amount of styrene and Bis-GMA, phenyl salicylic acid accounts for 10wt% of the total amount of styrene and Bis-GMA, and DMF accounts for 80wt% of the total amount of styrene and Bis-GMA;

[0060] 2) Preparation of modified titanium dioxide:

[0061] a) Disperse titanium dioxide in absolute ethanol and add n-butyl titanate dropwise to obtain a mixed dispersion after ultrasonic stirring, wherein the mass ratio of titanium dioxide, absolute ethanol and n-butyl titanate in the mixed dispersion is 4:150: 1;

[00...

Embodiment 2

[0072] A method for extinction and anti-ultraviolet high-performance PET film, the steps are as follows:

[0073] (1) Preparation of core-shell structure organic / inorganic composite hollow porous microspheres:

[0074] 1) Styrene, EBPADMA, CQ and p-tert-butyl salicylate are dissolved in chloroform to obtain an electrospray solution, and EBPADMA accounts for 15wt% of styrene and EBPADMA total amount in the electrospray solution, and chloroform accounts for benzene 56wt% of the total amount of ethylene and EBPADMA, CQ accounts for 0.6wt% of the total amount of styrene EBPADMA, and p-tert-butyl salicylate accounts for 15wt% of the total amount of styrene EBPADMA;

[0075] 2) Preparation of modified titanium dioxide:

[0076] a) Disperse titanium dioxide in absolute ethanol and add n-butyl titanate dropwise to obtain a mixed dispersion after ultrasonic stirring, wherein the mass ratio of titanium dioxide, absolute ethanol and n-butyl titanate in the mixed dispersion is 5:200: 1;...

Embodiment 3

[0087] A method for extinction and anti-ultraviolet high-performance PET film, the steps are as follows:

[0088] (1) Preparation of core-shell structure organic / inorganic composite hollow porous microspheres:

[0089] 1) Dissolve the mixture of styrene, UDMA, DMPOH and CQ (mass ratio is 1:1) and 2-hydroxy-4-methoxybenzophenone in dichloromethane to obtain the electrospray solution, in the electrospray solution UDMA accounts for 5wt% of the total amount of styrene and UDMA, dichloromethane accounts for 70wt% of the total amount of styrene and UDMA, the mixture of DMPOH and CQ accounts for 1.8wt% of the total amount of styrene and UDMA, 2-hydroxyl-4-methyl Oxybenzophenone accounts for 20wt% of styrene and UDMA total amount;

[0090] 2) Preparation of modified titanium dioxide:

[0091] a) Disperse titanium dioxide in absolute ethanol and add n-butyl titanate dropwise to obtain a mixed dispersion after ultrasonic stirring, wherein the mass ratio of titanium dioxide, absolute e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com