Method for producing plated steel sheet excellent in surface quality and press formability, and plated steel sheet produced by the method

A surface quality and manufacturing method technology, applied in the direction of manufacturing tools, chemical instruments and methods, furnace types, etc., can solve problems such as uneconomical, poor weldability or adhesion, expensive lubrication treatment, etc., to prevent the coating from falling off and the surface Excellent quality and press workability, and the effect of reducing sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, the present invention will be described in more detail through examples. However, the following examples are merely illustrative for explaining the present invention in more detail, and do not limit the scope of rights of the present invention. This is because the scope of rights of the present invention is determined by the content described in the claims and the content reasonably derived therefrom.

[0063] (Example)

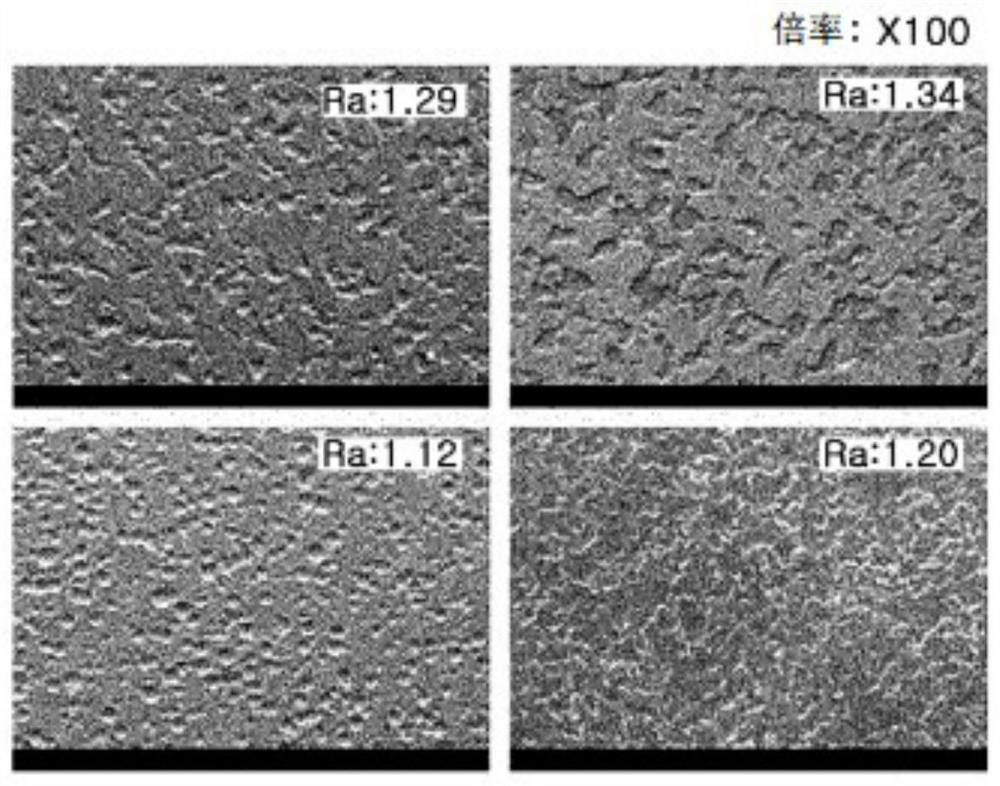

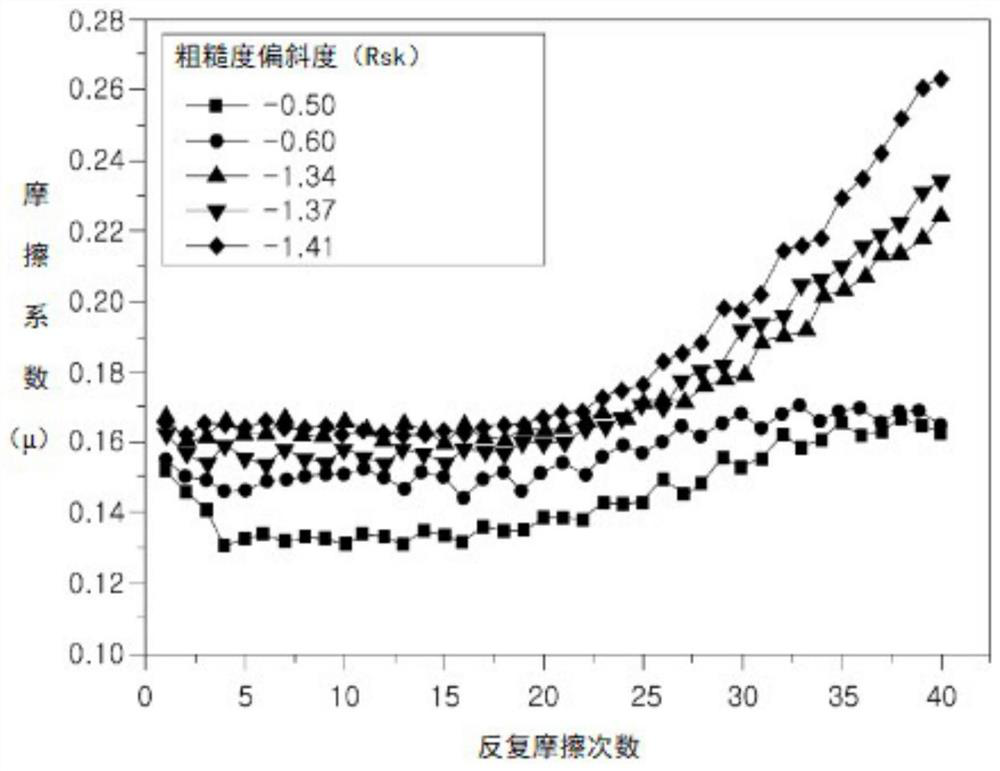

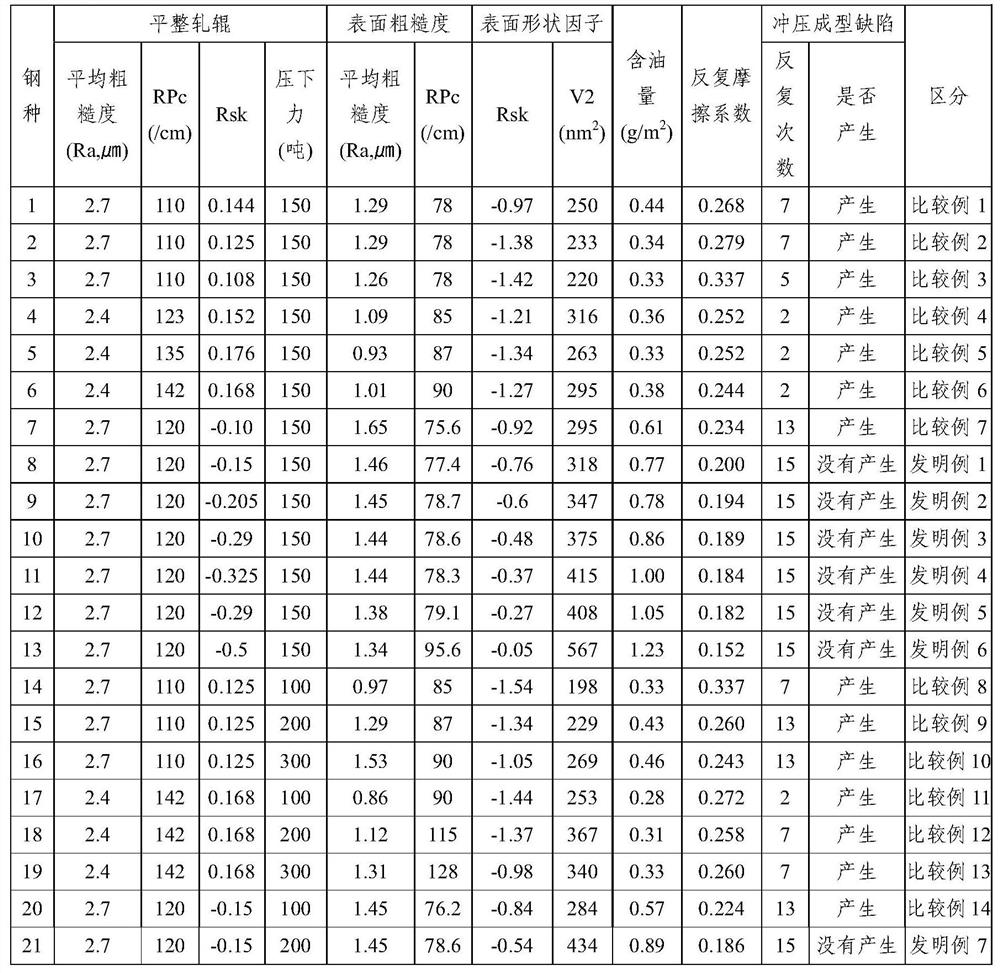

[0064] As a base steel sheet, a cold-rolled steel sheet having a composition of 0.002% of C, 0.003% of Si, 0.08% of Mn, 0.028% of Al, 0.0114% of P, and 0.0052% of S was prepared. The steel plate is hot-dip galvanized so that the coating weight on one side of the cold-rolled steel plate is 60g / m 2 , so as to obtain hot-dip galvanized steel sheet. Then, the hot-dip galvanized steel sheet is subjected to electric discharge processing (EDT) or superfinishing and TOPOCROM processing (TCT) after electric discharge processing (EDT), and the av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com