Flexible bonding electroconductive adhesive and preparation method thereof

A conductive adhesive and flexible technology, applied in the field of conductive adhesive, can solve the problems of being unable to meet the needs of flexible conductive bonding of flexible electronic products, not being able to bend and curl, and not being flexible enough, so as to save baking energy and work for a long time , the effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

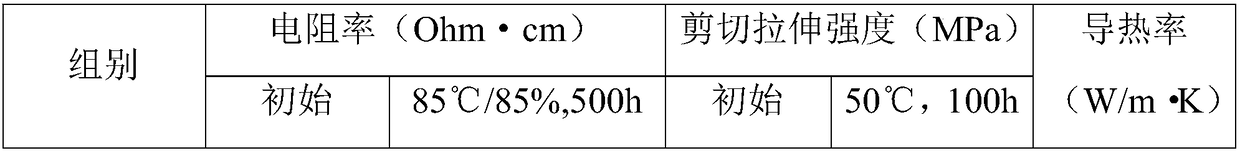

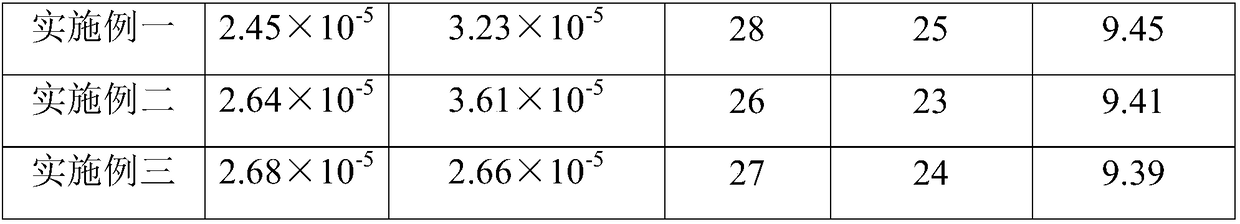

Embodiment 1

[0022] This embodiment provides a flexible bonding conductive adhesive. The raw material components include: 9.8 parts of flexible amorphous polyester resin, 2.8 parts of alicyclic epoxy resin, 1.4 parts of pressure-sensitive acrylic resin, based on 0.2 parts of hexamethylene diisocyanate blocking curing agent, 0.3 parts of hexafluoroantimonate, 1.0 parts of epoxy silane coupling agent, 14.5 parts of diethylene glycol butyl ether acetate, and a large particle size of 6 to 12 μm 63 parts of silver powder, 7 parts of silver powder with a particle size of 0.5-3 μm in small flakes.

[0023] According to above-mentioned raw material, adopt the preparation method of flexible bonding conductive glue provided by the present invention, prepare flexible bonding conductive glue:

[0024] S1: Mix flexible polyester resin and diethylene glycol butyl ether acetate at a mass ratio of 1:1, then heat and stir at 80°C for 5 hours to disperse the resin completely to obtain a dispersion;

[0025...

Embodiment 2

[0030] This embodiment provides a flexible bonding conductive adhesive. The raw material components include: 9 parts of flexible amorphous polyester resin, 2.5 parts of alicyclic epoxy resin, 1.3 parts of pressure-sensitive acrylic resin, based on 0.15 parts of hexamethylene diisocyanate blocking curing agent, 0.2 parts of hexafluoroantimonate, 0.8 parts of epoxy silane coupling agent, 14 parts of diethylene glycol butyl ether acetate, a large particle size of 6 to 12 μm 54 parts of silver powder, 6 parts of small silver powder with a particle size of 0.5-3 μm.

[0031] According to above-mentioned raw material, adopt the preparation method of flexible bonding conductive glue provided by the present invention, prepare flexible bonding conductive glue:

[0032] S1: Mix flexible polyester resin and diethylene glycol butyl ether acetate at a mass ratio of 1:1, then heat and stir at 80°C for 4 hours to completely disperse the resin to obtain a dispersion;

[0033] S2: Add cycloal...

Embodiment 3

[0038] This embodiment provides a flexible bonding conductive adhesive. The raw material components are calculated in parts by weight, including: 10 parts of flexible amorphous polyester resin, 3.0 parts of alicyclic epoxy resin, 1.5 parts of pressure-sensitive acrylic resin, based on 0.25 parts of hexamethylene diisocyanate blocking curing agent, 0.4 parts of hexafluoroantimonate, 1.2 parts of epoxy silane coupling agent, 15 parts of diethylene glycol butyl ether acetate, and a large particle size of 6-12 μm 72 parts of silver powder, 8 parts of silver powder with a particle size of 0.5-3 μm in small flake diameter.

[0039] According to above-mentioned raw material, adopt the preparation method of flexible bonding conductive glue provided by the present invention, prepare flexible bonding conductive glue:

[0040] S1: Mix flexible polyester resin and diethylene glycol butyl ether acetate at a mass ratio of 1:1, then heat and stir at 80°C for 6 hours to completely disperse th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com