Polyimide (PI) composite membrane for pervaporation separation of amide/water and preparation method thereof

A technology for separation of amides and pervaporation, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

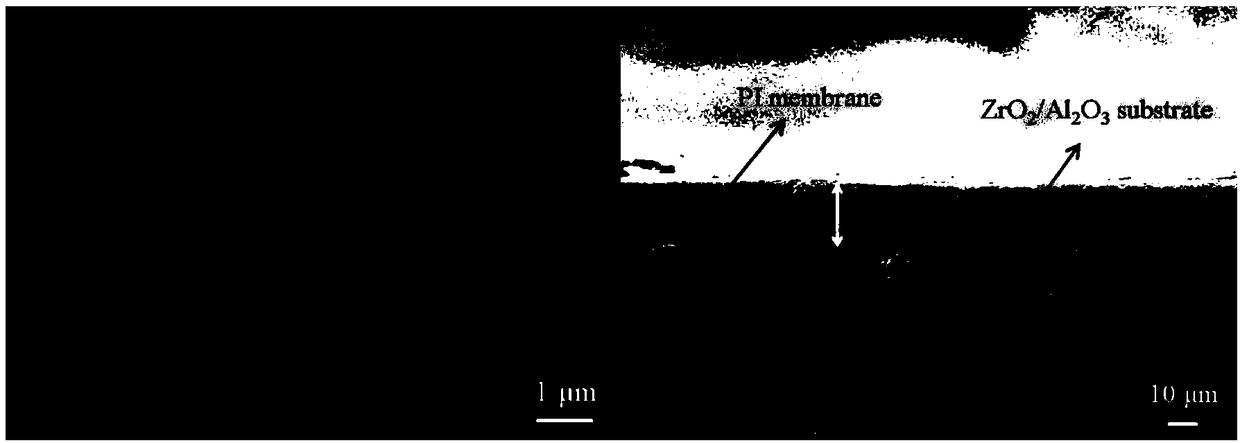

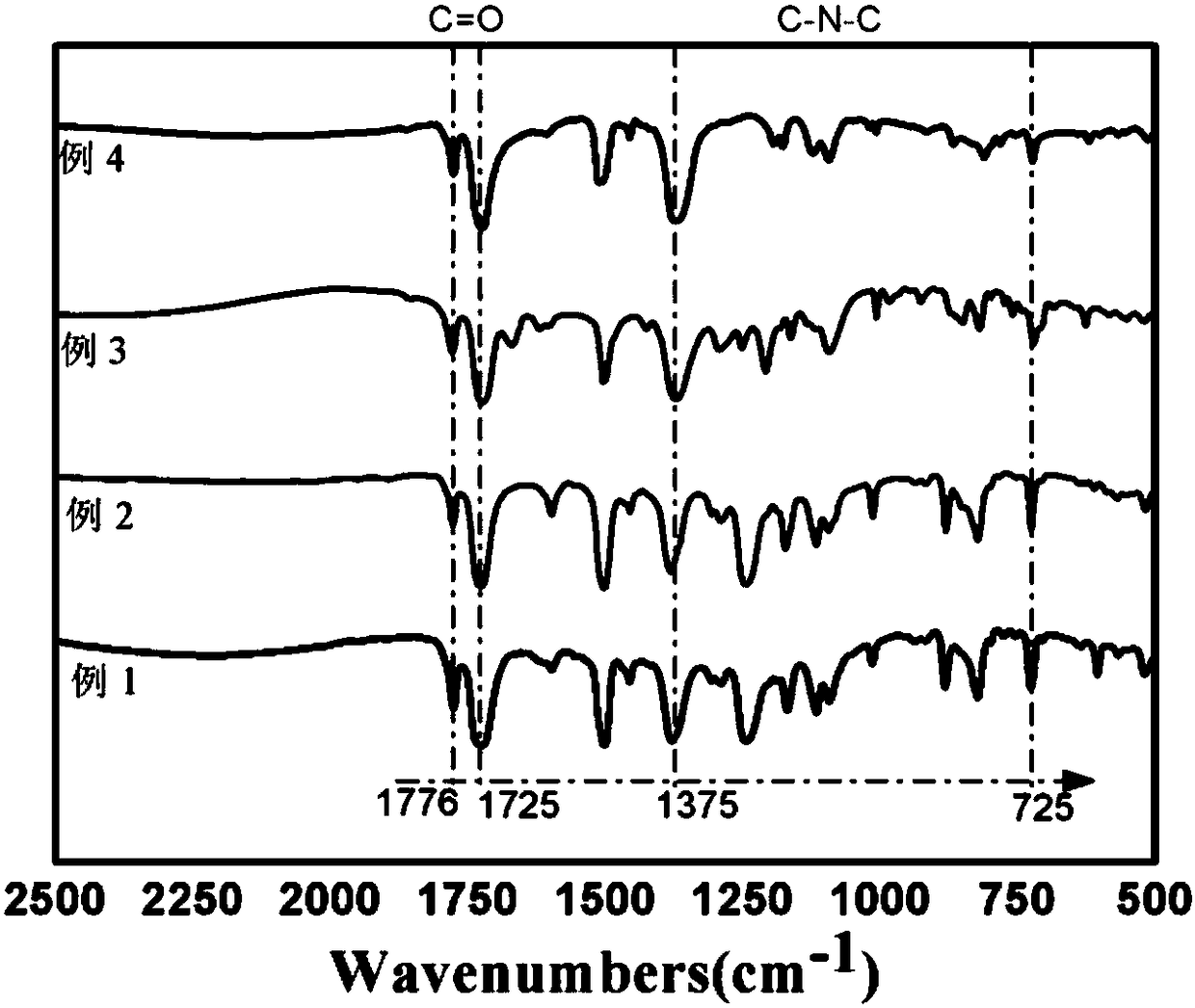

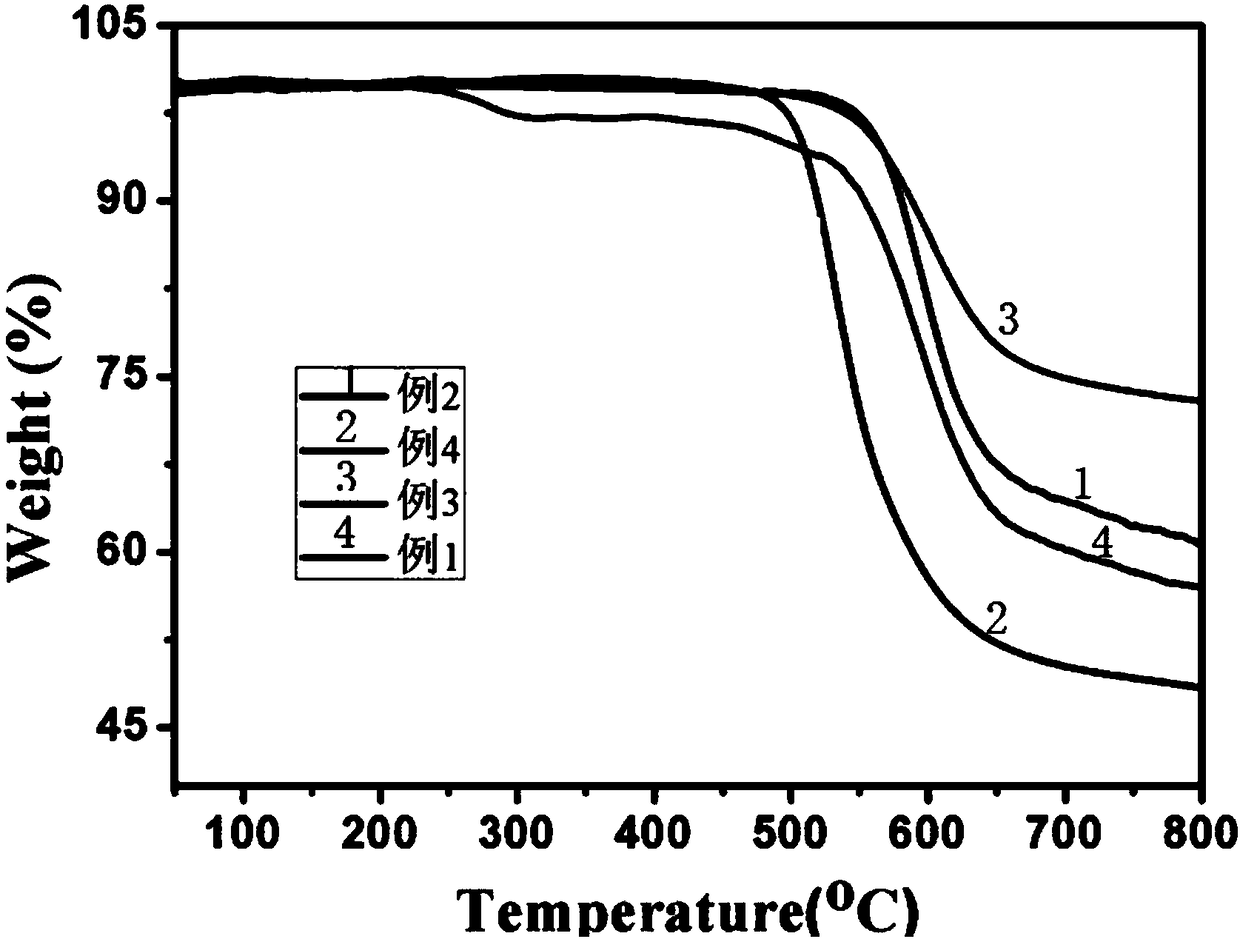

[0028] 5 mmol 4,4'-diaminodiphenyl ether, 5 mmol 3,5-diaminobenzoic acid, 10 mmol 3,3',4,4'-benzophenone tetraacid dianhydride (diamine After mixing with dianhydride molar ratio of 1:1) and 27 (solute to solvent mass ratio of 15:85) ml NMP, mechanically stir at room temperature for 20 minutes, stir and react in ice bath and nitrogen atmosphere for 3 hours, after the reaction is completed, degassing Finally, a PAA solution is obtained. The composite film was prepared by dipping and pulling method, and the PAA casting solution was evenly coated to a thickness of 2 mm on Al 2 o 3 On the surface of the porous base membrane, the PAA solution was spread on the surface to form a composite membrane, and then the composite membrane was placed in an oven for programmed temperature imidization reaction (150°C for 0.5h, 200°C for 1h, 250°C for 1h, 300°C for 1h ), naturally cooled to room temperature to obtain a composite membrane with a polyimide separation layer of 30 μm.

[0029] The...

Embodiment 2

[0036] 5 mmoles of 4,4'-diaminodiphenyl ether, 5 mmoles of 3,5-diaminobenzoic acid, 10.3 mmoles of pyromellitic dianhydride (the molar ratio of diamine to dianhydride is 1:1.03) and After mixing 23 ml of NMP (mass ratio of solute to solvent: 15:85), mechanically stir at room temperature for 20 min, stir and react in ice bath and nitrogen atmosphere for 3 h, and obtain PAA solution after degassing at the end of the reaction. The composite film was prepared by dipping and pulling method, and the PAA casting solution was uniformly coated to a thickness of 2 mm on Al 2 o 3 On the surface of the porous base membrane, spread the PAA solution on the surface to form a composite membrane, and then put the composite membrane into an oven for programmed temperature imidization reaction (150°C for 0.5h, 200°C for 1h, 250°C for 1h, 300°C for 1h ), naturally cooled to room temperature to obtain a composite membrane with a polyimide separation layer of 30 μm.

[0037] The separation perfor...

Embodiment 3

[0044] With 5 mmoles of benzidine, 5 mmoles of 4,4'-diaminodiphenyl ether, 10.3 mmoles of 3,3',4,4'-benzophenone tetraacid dianhydride (the molar ratio of diamine to dianhydride is 1:1.03) and 29 ml of NMP (the mass ratio of solute to solvent is 15:85), mechanically stirred at room temperature for 20 min, stirred and reacted in ice bath and nitrogen atmosphere for 3 h, and the PAA solution was obtained after degassing at the end of the reaction. The composite film was prepared by the dipping and pulling method, and the PAA casting solution was evenly coated to the ZrO with a thickness of 2mm. 2 On the surface of the porous base membrane, spread the PAA solution on the surface to form a composite membrane, and then put the composite membrane into an oven for programmed temperature imidization reaction (150°C for 0.5h, 200°C for 1h, 250°C for 1h, 300°C for 1h ), naturally cooled to room temperature to obtain a composite membrane with a polyimide separation layer of 30 μm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com