Thermal sprayed coating anti-reflection protective layer applicable to selective absorption of medium and high-temperature solar energy and preparation method of thermal sprayed coating anti-reflection protective layer

A technology of thermal spraying and protective layer, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve problems such as the decline of the absorption performance of the coating, improve the surface state, increase the absorption rate, reduce the infrared The effect of emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

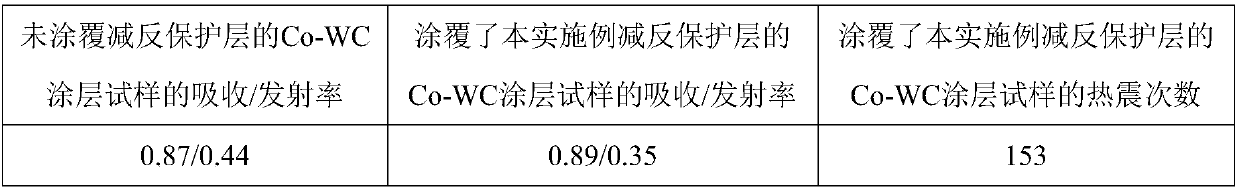

Embodiment 1

[0027] A kind of anti-reflection protective layer suitable for solar energy selective absorption Co-WC thermal spray coating is prepared by the following method:

[0028] (1) 40wt%Co 3 o 4 -CoAl 2 o 4 The preparation of sol: weigh 6.909g Co(NO 3 ) 2 ·6H 2 O, 3.918gC 9 h 21 AlO 3 , measure 139ml absolute ethanol, weigh the Co(NO 3 ) 2 ·6H 2 O was added to absolute ethanol to prepare a 0.138mol / L A solution; measure 172ml of deionized water, and weighed C 9 h 21 AlO 3 Add in deionized water, stir magnetically at 80°C until completely dissolved, and prepare solution B with the same concentration; slowly add solution A to suspension B to obtain solution C, adjust the temperature of the water bath to 85°C, and stir for 1 hour at a constant temperature in the open to make Evaporate the alcohol to speed up the hydrolysis rate, then replenish water to the original position; then raise the temperature to 90°C, add 3 times diluted concentrated nitric acid dropwise during t...

Embodiment 2

[0035] A kind of anti-reflection protective layer suitable for solar energy selective absorption Co-WC thermal spray coating is prepared by the following method:

[0036] (1) Preparation of 40wt% Co by sol-gel method 3 o 4 -CoAl 2 o 4 Sol: Weigh 6.909g Co(NO 3 ) 2 ·6H 2 O, 3.918gC 9 h 21 AlO 3 , measure 139ml of absolute ethanol, and weigh the Co(NO 3 ) 2 ·6H 2 O was added to absolute ethanol to prepare a 0.138mol / L A solution; measure 172ml of deionized water, and weighed C 9 h 21 AlO 3 Add in deionized water, stir magnetically at 80°C until completely dissolved, and prepare solution B with the same concentration; slowly add solution A to suspension B to obtain solution C, adjust the temperature of the water bath to 85°C, and stir for 1 hour at a constant temperature in the open to make Evaporate the alcohol to speed up the hydrolysis rate, then replenish water to the original position; then raise the temperature to 90°C, add 3 times diluted concentrated nitric ...

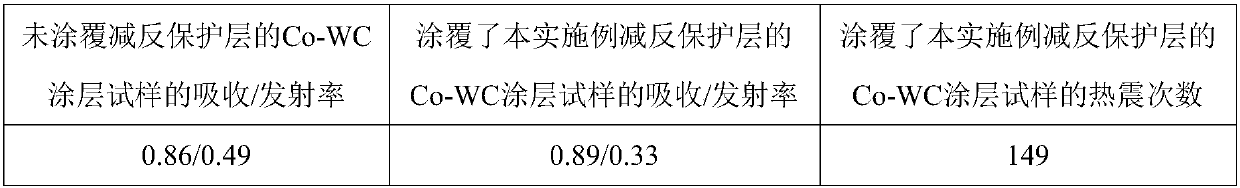

Embodiment 3

[0043] A kind of anti-reflection protective layer suitable for solar energy selective absorption Co-WC thermal spray coating is prepared by the following method:

[0044](1) Preparation of 40wt% Co by sol-gel method 3 o 4 -CoAl 2 o 4 Sol: Weigh 6.909g Co(NO 3 ) 2 ·6H 2 O, 3.918gC 9 h 21 AlO 3 , measure 139ml of absolute ethanol, and weigh the Co(NO 3 ) 2 ·6H 2 O was added to absolute ethanol to prepare a 0.138mol / L A solution; measure 172ml of deionized water, and weighed C 9 h 21 AlO 3 Add in deionized water, stir magnetically at 80°C until completely dissolved, and prepare solution B with the same concentration; slowly add solution A to suspension B to obtain solution C, adjust the temperature of the water bath to 85°C, and stir for 1 hour at a constant temperature in the open to make Evaporate the alcohol to speed up the hydrolysis rate, then replenish water to the original position; then raise the temperature to 90°C, add 3 times diluted concentrated nitric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com