Preparation method of metal grid membrane

A metal mesh and metal technology, applied in the field of metal mesh film preparation, can solve the problems of difficult control of metal nanowire coating or mesh assembly process, complicated steps, complex metal nanowires, etc., and achieve accurate optical transmittance controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a method for preparing a metal mesh film, which includes the following steps:

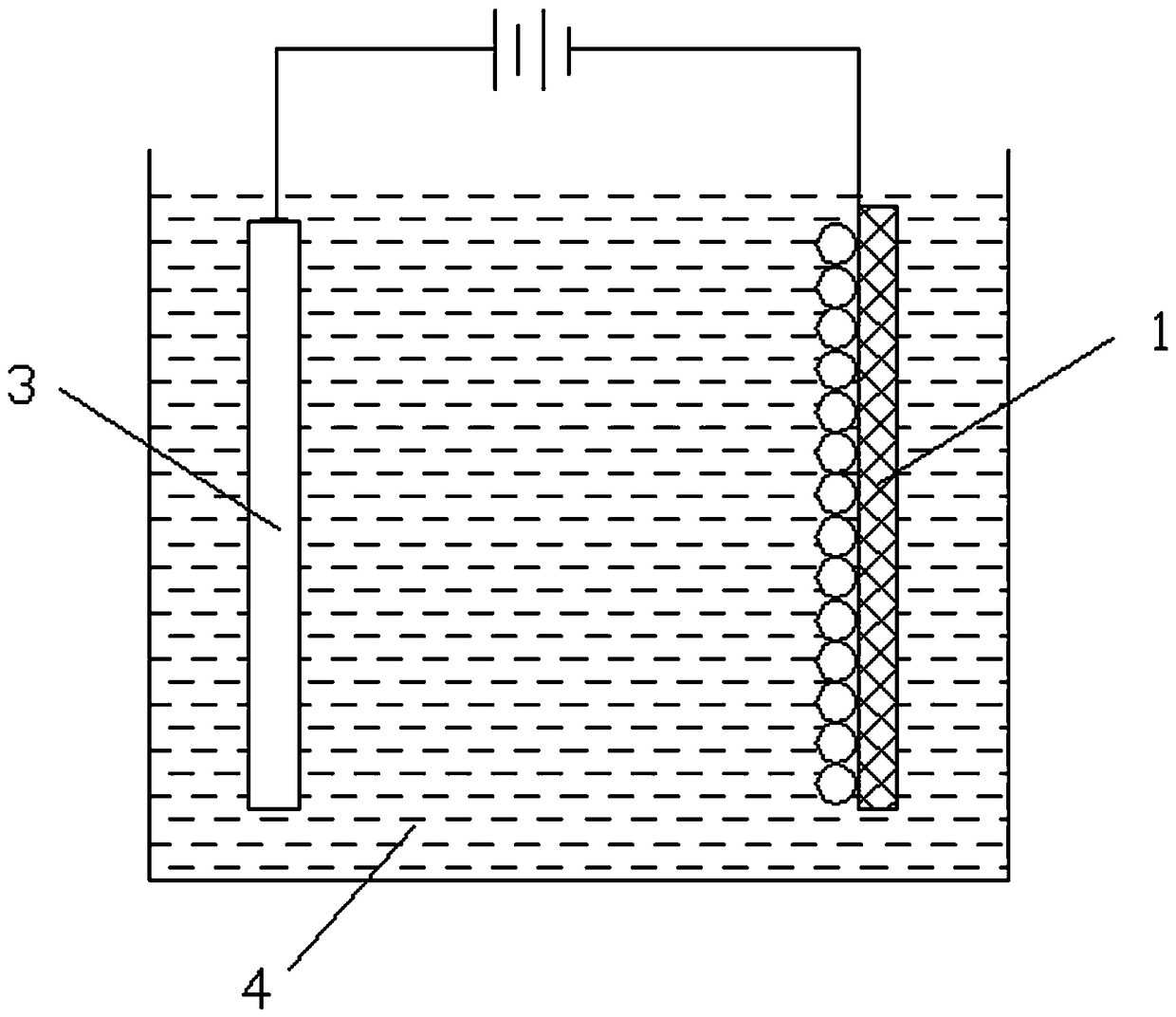

[0028] S1, such as figure 1 As shown, a uniform single-layer polystyrene microsphere colloidal crystal 2 is prepared on the surface of the substrate 1 using the vertical immersion self-assembly method, the direct dropping method of polystyrene emulsion, the spin coating method of polystyrene emulsion, or the LB interface method; Use ITO glass substrate or flexible conductive substrate;

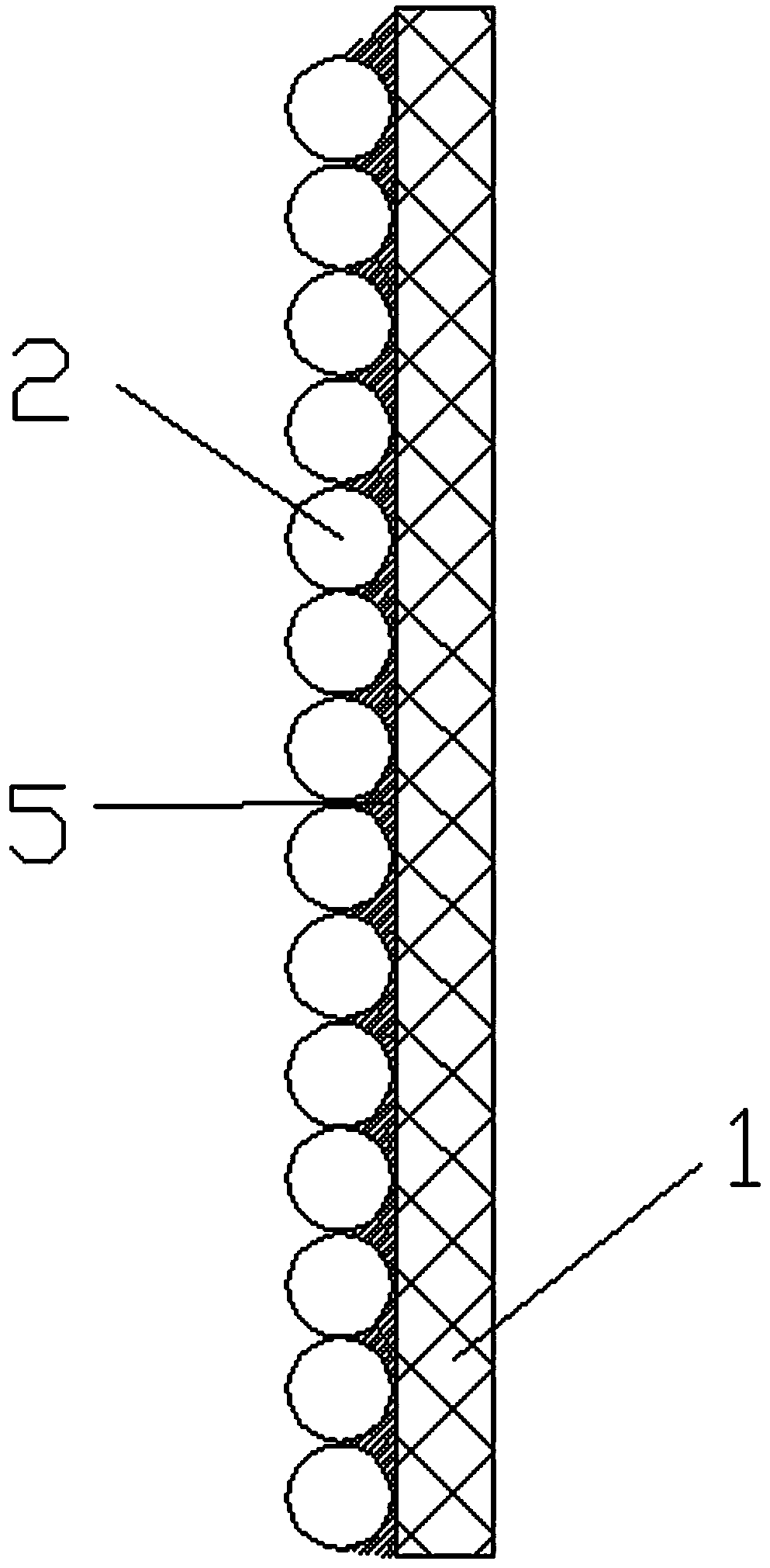

[0029] S2, combine figure 2 versus image 3 As shown, the substrate 1 treated in step S1 is used as the cathode, the metal 3 to be plated is used as the anode, the salt solution of the metal is used as the electroplating solution 4, the electrochemical deposition process is adopted, and the single-layer polystyrene microsphere colloid Crystal 2 is a template for depositing a metal layer 5 on the surface of the substrate;

[0030] The metal to be plated can be copper, aluminum, zinc,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com