Device and method for preventing secondary oxidation of molten steel

A secondary oxidation and molten steel technology, applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems that the argon gas is easy to move downward, does not reach the ideal, and the operation is difficult, etc., and achieves simple structure, The effect of reducing inclusions and improving the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

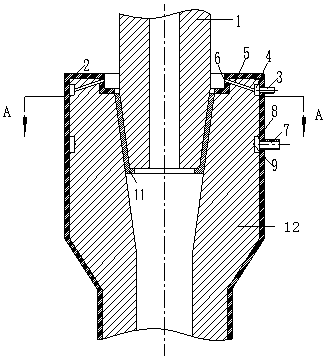

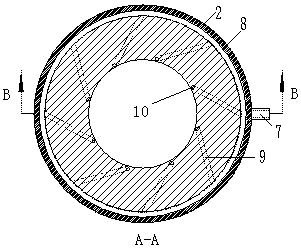

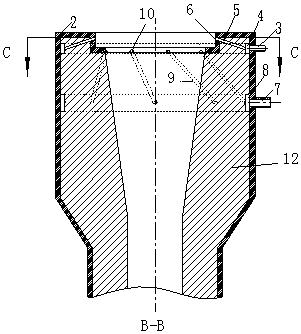

[0041] The ladle lower nozzle 1 is connected with the ladle long nozzle 12, and the quantity of the upper layer air intake pipeline 5 is 8, which are evenly and symmetrically distributed on the upper layer air intake channel 4, and the upper layer air intake pipeline 5 is inclined upward by 30 degrees in the vertical direction; The quantity of air pipeline 9 is 8, and is evenly and symmetrically distributed on the lower floor air intake channel 8, and the lower floor air intake pipeline 9 is upwardly inclined 30 degrees in the vertical direction, and is inclined 30 degrees in the horizontal direction.

[0042] Before the molten steel is poured, the worker places the sealing bowl 11 in the ladle shroud 12, and then connects the ladle shroud 12 with the ladle lower nozzle 1 through a mechanical arm, and tightens the ladle lower nozzle 1 with the ladle shroud 12, and the ladle is lowered The lower end surface of the nozzle 1 is compacted with the upper surface of the annular botto...

Embodiment 2

[0044] The ladle lower nozzle 1 is connected with the ladle long nozzle 12, and the quantity of the upper layer air intake pipeline 5 is 8, which are evenly and symmetrically distributed on the upper layer air intake channel 4, and the upper layer air intake pipeline 5 is inclined upward by 40 degrees in the vertical direction; The quantity of air pipeline 9 is 8, and is evenly and symmetrically distributed on the lower floor air intake channel 8, and the lower floor air intake pipeline 9 is upwardly inclined 40 degrees in the vertical direction, and is inclined 40 degrees in the horizontal direction.

[0045] Before the molten steel is poured, the worker places the sealing bowl 11 in the ladle shroud 12, and then connects the ladle shroud 12 with the ladle lower nozzle 1 through a mechanical arm, and tightens the ladle lower nozzle 1 with the ladle shroud 12, and the ladle is lowered The lower end surface of the nozzle 1 is compacted with the upper surface of the annular botto...

Embodiment 3

[0047] The ladle lower nozzle 1 is connected with the ladle long nozzle 12, and the quantity of the upper layer air intake pipeline 5 is 8, which are uniformly and symmetrically distributed on the upper layer air intake channel 4, and the upper layer air intake pipeline 5 is inclined upward by 35 degrees in the vertical direction; The quantity of air pipeline 9 is 8, and is evenly and symmetrically distributed on the lower floor air intake channel 8, and the lower floor air intake pipeline 9 is upwardly inclined 35 degrees in the vertical direction, and is inclined 30 degrees in the horizontal direction.

[0048] Before the molten steel is poured, the worker places the sealing bowl 11 in the ladle shroud 12, and then connects the ladle shroud 12 with the ladle lower nozzle 1 through a mechanical arm, and tightens the ladle lower nozzle 1 with the ladle shroud 12, and the ladle is lowered The lower end surface of the nozzle 1 is compacted with the upper surface of the annular bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com