Low-temperature ozone waste pyrolysis treatment device and method

A treatment device, ozone technology, applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of smoke pollution, greenhouse effect, and insignificant benefits, and achieve small smoke output, reduce energy, and improve The effect of pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

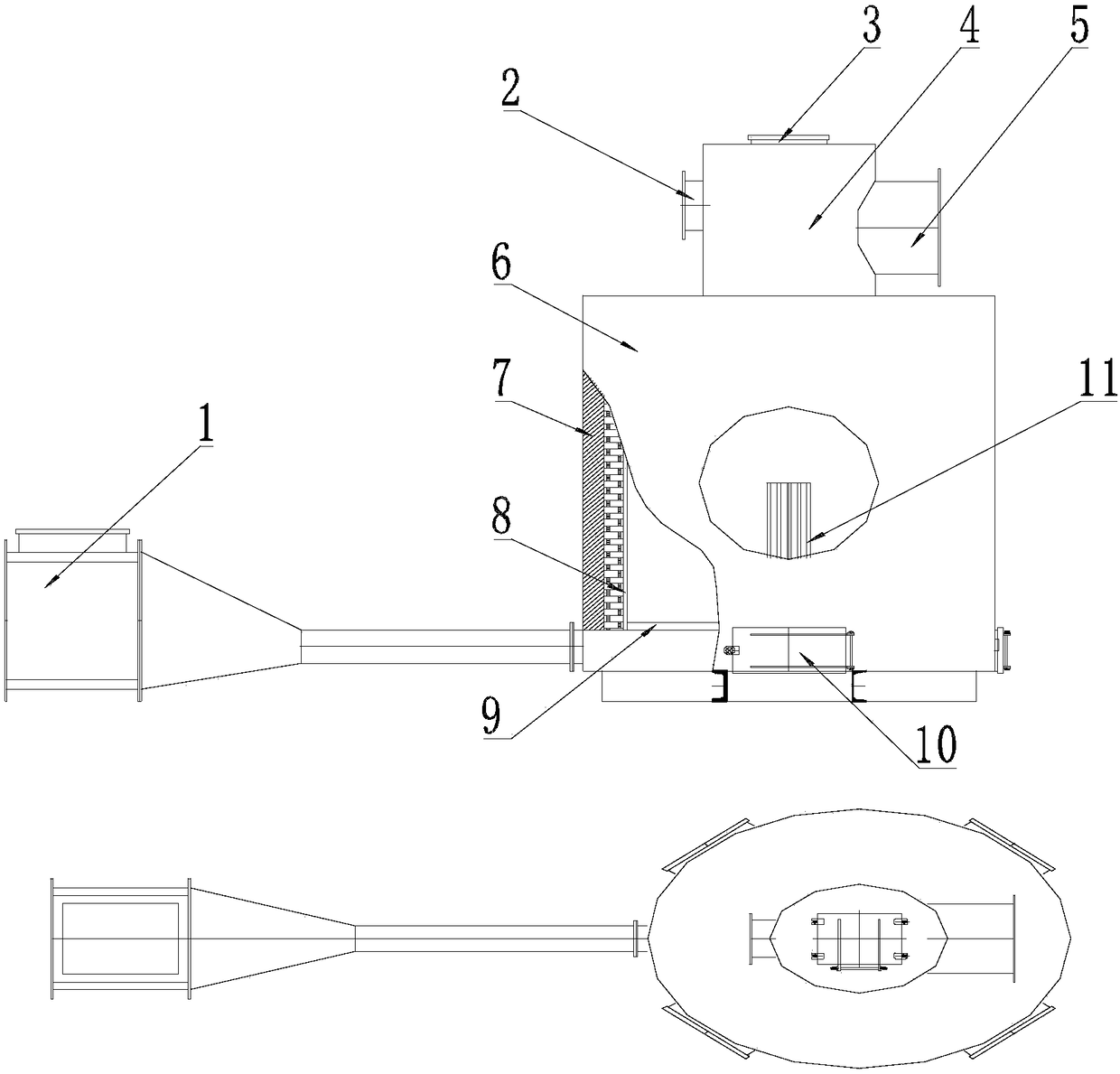

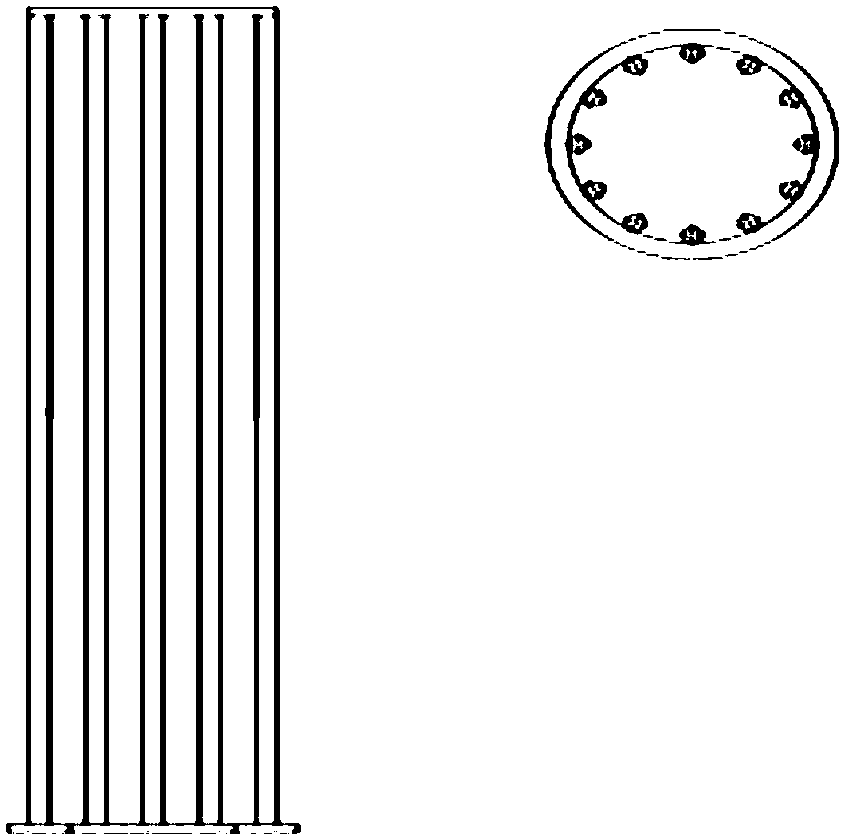

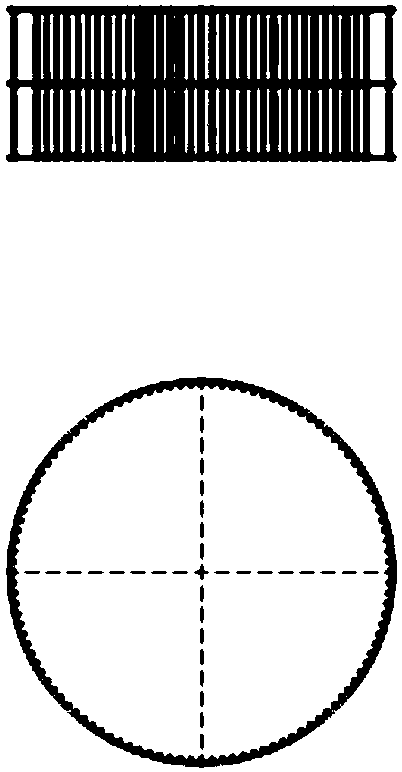

[0033] like figure 1A low-temperature ozone garbage pyrolysis treatment device is shown, which includes a low-temperature ozone garbage pyrolysis furnace and an ozone generator 1 connected to each other. The low-temperature ozone garbage pyrolysis furnace includes a base, a furnace body 6, and a top of the furnace body 6 The feed box 4 provided, the insulation layer 7 provided on the side of the furnace body 6, the squirrel-cage ventilation grill assembly 8 inside the insulation layer 7, the squirrel-cage central ventilation pipe 11 arranged at the center of the furnace body 6, the furnace The ventilation grate grate 9 arranged at the lower end of the body 6, the ozone air inlet provided on the side of the furnace body on the lower side of the ventilation grate grate 9, the ash discharge door 10 provided at the bottom of the furnace body 6, and the ozone generator 1 passes through the air supply duct It communicates with the ozone air inlet of the furnace body 6 of the low-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com