Preparation method of capacitive stress sensing intelligent fabric

A stress-sensing, capacitive technology, applied in the field of textile fabrics, can solve the problems of complex manufacturing process, poor wearing comfort and complex structure of sensor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

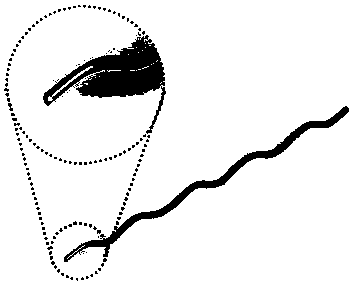

[0025] A method for preparing a yarn-like sensor integrated with a dielectric material and an electrode and a woven fabric sensor array. This embodiment uses polydimethylsiloxane (PDMS), styrene-butadiene-styrene (SBS ) and other insulating elastomers or a mixture of several. The modulus of elasticity of the elastomer can be controlled by controlling the ratio of the prepolymer to its crosslinking agent. The range of modulus can vary from 2MPa to 40MPa, and the corresponding sensitivity range is 0.01 to 4KPa. -1 , the lower the modulus, the higher the sensitivity. When the sensitivity is higher than 0.5KPa -1 When it is used, it can be used to monitor the physiological state of the human body such as heartbeat and pulse; sensors with lower sensitivity can be used for touch sensing of smart clothing and smart homes.

[0026] Conductive yarns are prepared with one or more mixtures of metal, carbon or conductive polymers as the conductive main body. The direct preparation metho...

Embodiment 2

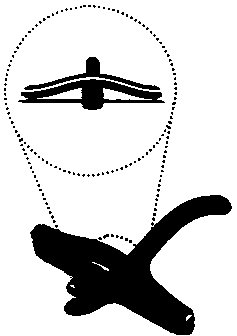

[0032] A method for preparing a yarn or fibrous sensor and a knitted fabric sensor array based on a conductive polymer-based dielectric material integrated with an electrode. The preparation method of the yarn or fibrous sensor and the fabric sensor array with the conductive polymer as the electrode, using a combination of polyurethane (PU) and polyhydrogenated styrene-polyethylene butene-polystyrene block copolymer (SEBS) One or more mixtures are used as insulating elastomers, and the integrated yarn or fiber sensor is prepared by melt extrusion and direct coating method and applied in knitted fabrics.

[0033] The conductive yarn uses PEDOT:PSS (poly(3,4-ethylenedioxythiophene): polystyrene sulfonic acid) and its ductile conductive enhancer (dodecylbenzenesulfonic acid, sodium dodecylbenzenesulfonate ) or polyaniline (PAni) as raw material to prepare conductive fibers or yarns by wet spinning. Taking polyaniline as an example, dissolve polyaniline with a mass fraction of 20...

Embodiment 3

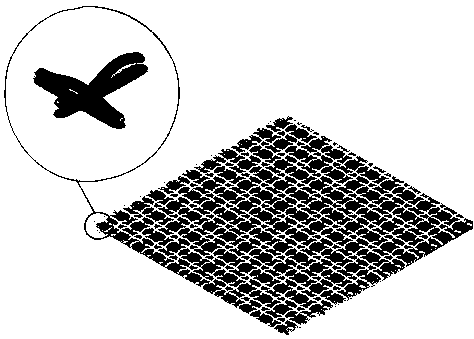

[0037] A capacitive sensor based on conductive yarn and its application in three-dimensional fabric reinforcement composite materials. Three-dimensional fabrics are often used as reinforcements for engineering composite materials due to their varied three-dimensional structures and convenient processing methods. The embodiment utilizes conductive yarn and insulating resin to compound, and provides a capacitive sensor that can monitor the deformation of engineering composite materials in real time.

[0038]Preparation of conductive yarn: The conductive yarn adopts the same method as in Example 1 and Example 2, and one or more mixtures of metal, carbon or conductive polymers are used as the conductive main body to prepare the yarn, and the direct preparation method is used. To enhance the strength of the conductive yarn, the conductive yarn is also prepared by doping and coating conductive metal and carbon nanomaterials on high-strength and high-modulus yarns such as nylon and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com