Preparation method of graphene-reinforced aluminum-based composite material

An aluminum composite material and composite material technology, applied in the field of preparation of graphene-reinforced aluminum-based composite materials, can solve the problem of difficulty in obtaining powders with uniform distribution of graphene content, failure to obtain graphene/aluminum powder combination, and unfavorable mechanical properties of materials and other problems, to achieve high density, prevent agglomeration, and high volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

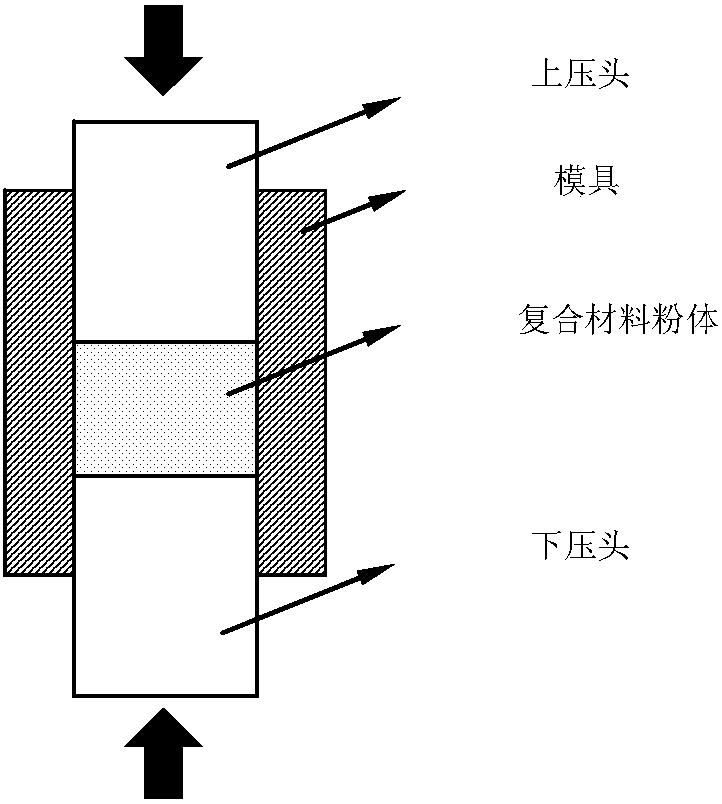

[0038] The preparation graphene volume fraction is the FLG / Al composite material of 1vol.%, concrete steps are as Figure 8 Shown:

[0039] 1. Graphene / aluminum mixed powder

[0040] Weigh the aluminum powder and graphene powder according to the graphene volume fraction of 1vol.%, and put them into a stainless steel ball mill jar; add 1-1.5g of stearic acid per 100g of mixed powder; according to the ball-to-material ratio of 5:1-10 : 1. Weigh the balls according to the total mass of the mixed powder and put them into the ball mill tank; ensure that the filling factor is between 0.5 and 0.7. The ball mill jar was filled with powder in an argon atmosphere glove box. The aluminum powder that adopts in this step can be pure aluminum powder or 1XXX series~8XXX series aluminum alloy powder; The graphene that uses can be the graphene sheet or graphene oxide sheet that physical method or chemical method prepare, and its thickness can be in 1~8XXX series. Between 20nm and sheet diam...

Embodiment 2

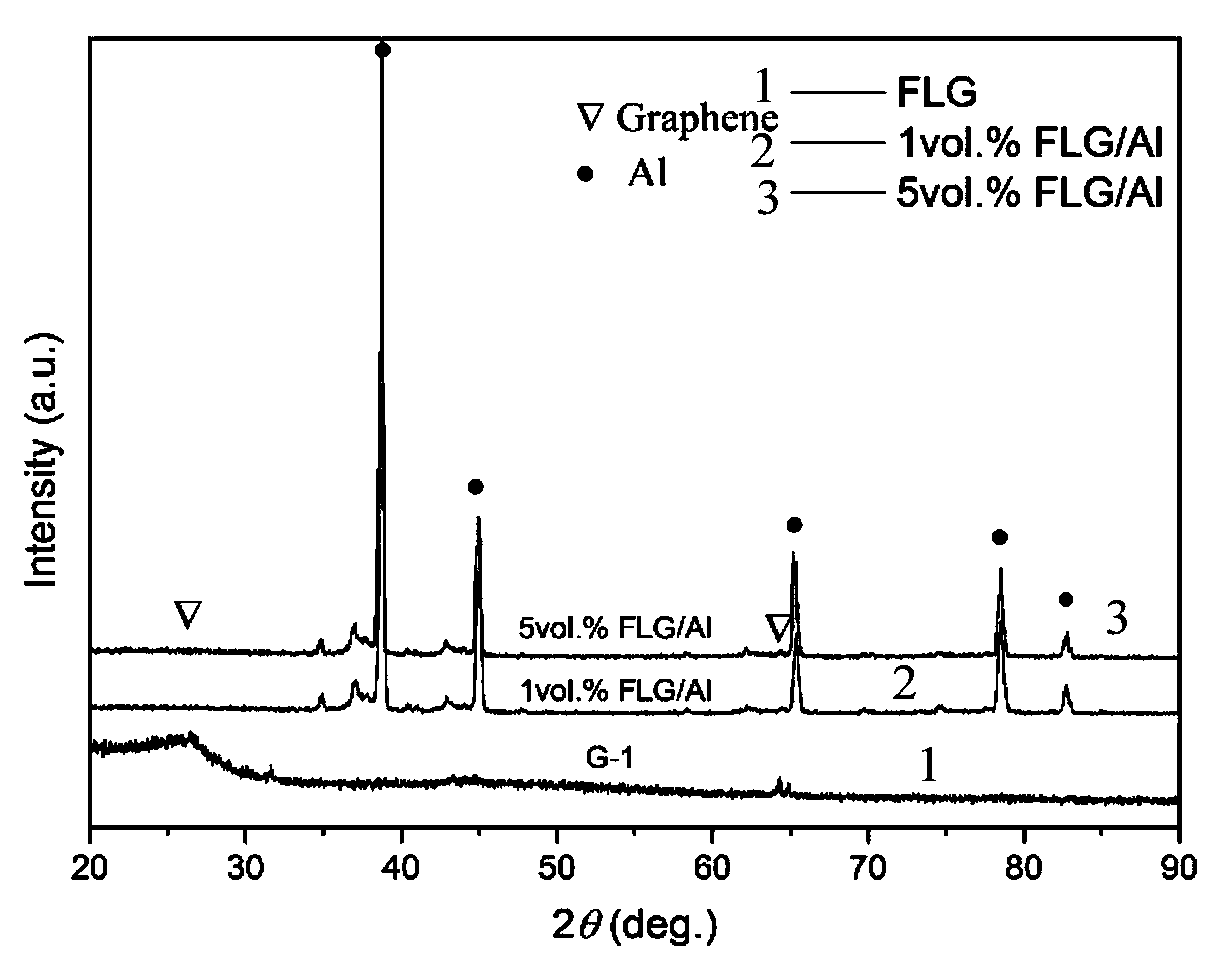

[0051] The FLG / Al composite material that adopts above-mentioned process to prepare graphene volume fraction to be 5vol.%, the graphene / aluminum mixed powder that present embodiment obtains is as follows figure 1 , 2 shown.

[0052] Such as Figure 5 It has been shown that pure aluminum and graphene volume fraction are respectively 1vol.% (embodiment 1) and 5vol.% (embodiment 2) FLG / Al composite material is in the density change situation under different states in the preparation process, can be seen from the figure It can be seen that the density of the composite powder state is about 45%, and its density can reach more than 90% after cold pressing, and the density of composite materials can reach more than 99% after hot extrusion.

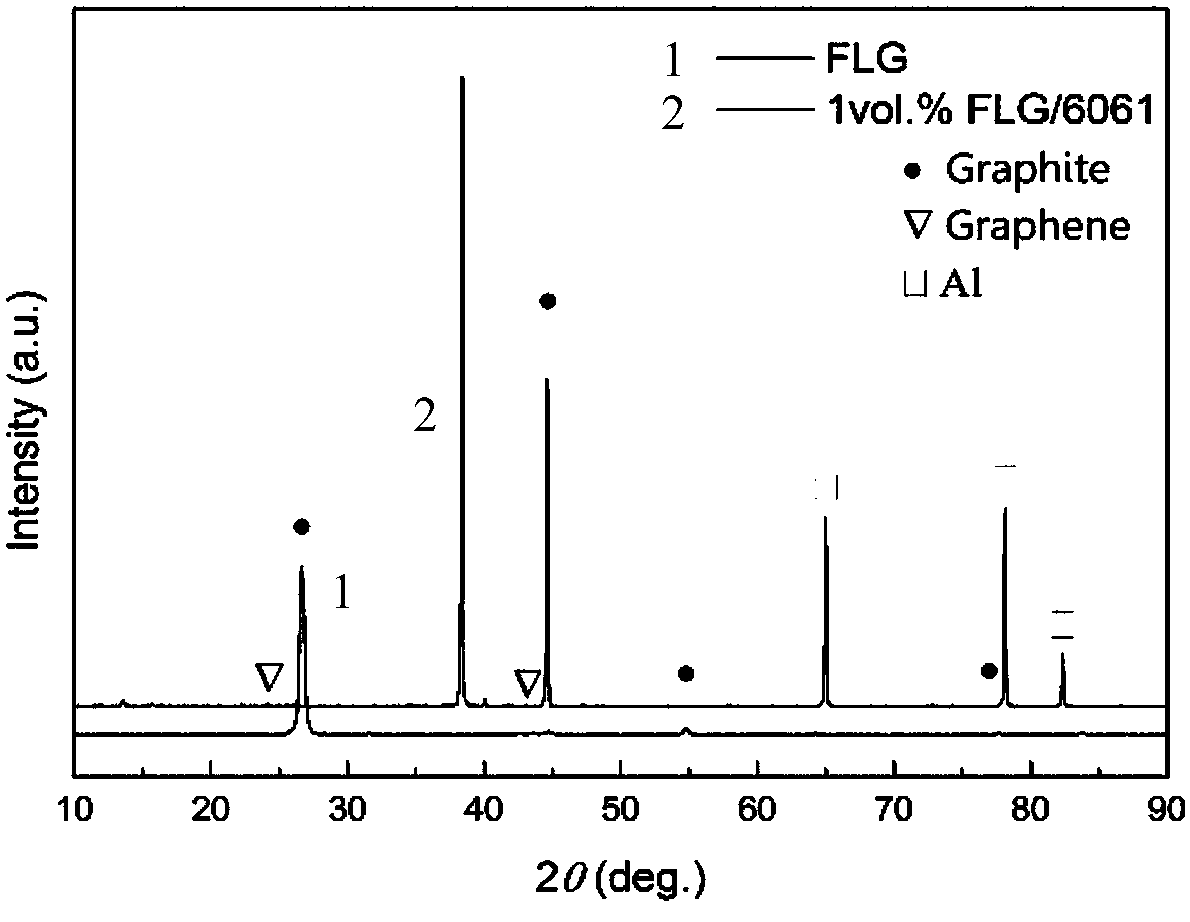

Embodiment 3、4、5

[0054] 1. Graphene / 6061 aluminum mixed powder

[0055] 6061 aluminum alloy powder and graphene powder were weighed according to the graphene volume fractions of 1vol.%, 2vol.%, and 5vol.%, respectively, and put into a stainless steel ball mill tank; the remaining ball mill settings were the same as in Example 1.

[0056] Use a planetary ball mill, mill at a speed of 120-180rpm for 10-12 hours, and stop for 15-30 minutes every 1-1.5 hours; use a speed of 240-300RPM for 10-12 hours, stop for 15-30 minutes every 1-1.5 hours. After ball milling, the powder was collected in a glove box with an argon atmosphere.

[0057] 2. Under the pressure of 250Mpa and the holding time of 20min, the FLG / 6061Al composite billet without cracks is formed by cold pressing.

[0058] 3. Hot extrusion

[0059] The preheating temperature is 440-460°C, the heating rate is 5-10°C / min, and the holding time is 1-3 hours. The preheated billet is extruded, the extrusion ratio is between 10:1, 20:1 and 40:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com