A method of doping micro-nano particles into liquid metal and its application

A technology of micro-nano particles and liquid metal, which is applied in the field of doping micro-nano particles, can solve problems such as doping of micro-nano particles, oxidation of liquid metal mixed systems, and influence on the use of liquid metal, and achieve simple process, good magnetic properties, and improved qualitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

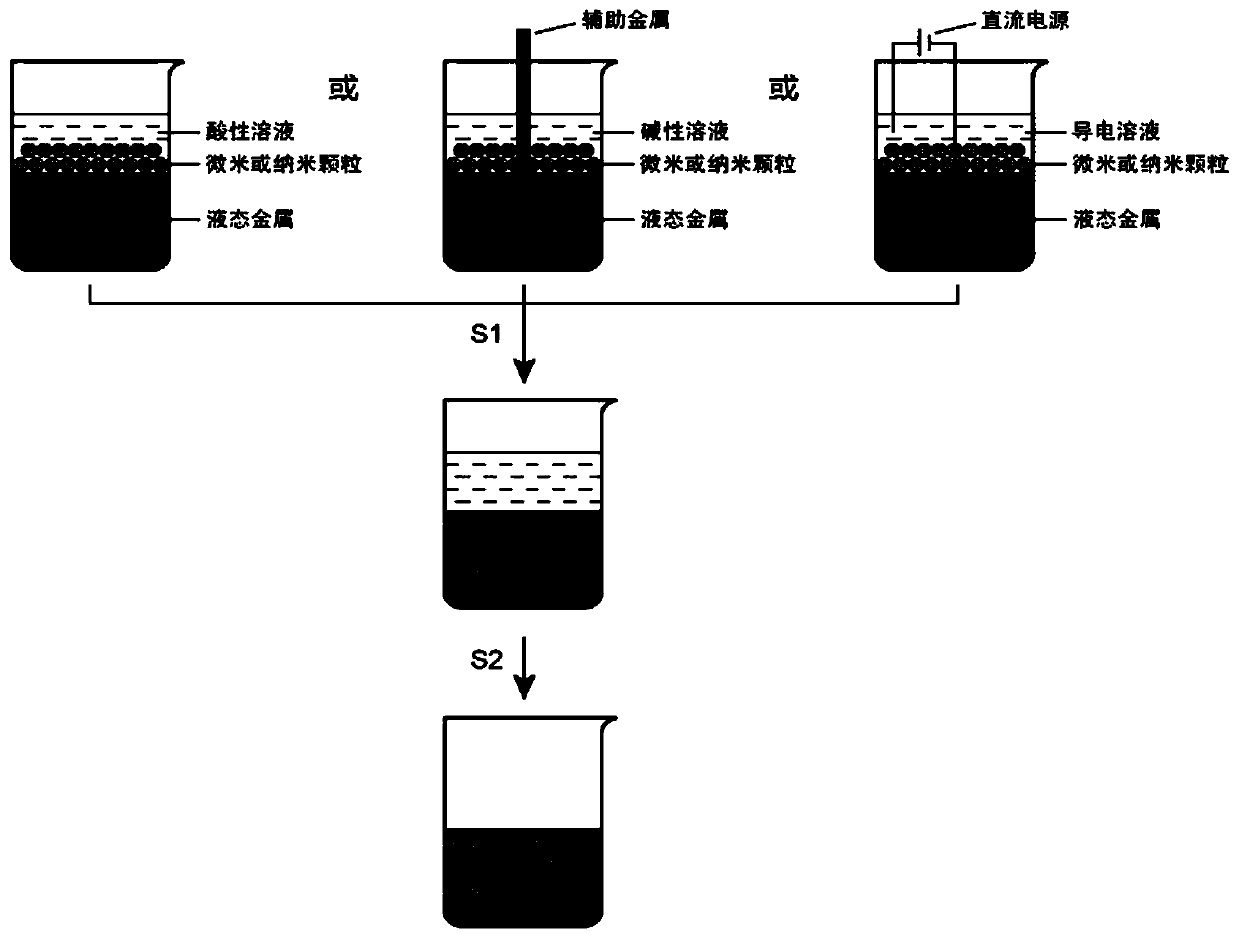

[0033] This embodiment provides a method for preparing a liquid metal-micro-nano particle mixture, which includes the following steps:

[0034] S1, 1g of copper nanoparticles with a particle size of 50nm and 19g of gallium-indium alloy (Ga 75.5 In 24.5 ) are respectively added into an aqueous hydrochloric acid solution having the same volume as the gallium-indium alloy and having a pH value of 1;

[0035] S2. Stir the aqueous hydrochloric acid solution added with gallium-indium alloy and copper nanoparticles with a magnetic stirrer for 5 minutes, and let it stand to make it divided into two layers, namely the liquid metal-micro-nanoparticle mixture located in the lower part and the aqueous hydrochloric acid solution located in the upper part;

[0036] S3, removing the aqueous hydrochloric acid solution in the upper part, and then vacuum-drying the liquid metal-micronano particle mixture in the lower part at room temperature for 1 hour to obtain the final product.

[0037] It...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the only difference is that the pH value is 3.

Embodiment 3

[0041] This example is basically the same as Example 1, the only difference being that the hydrochloric acid aqueous solution in Example 1 is replaced by sulfuric acid aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com