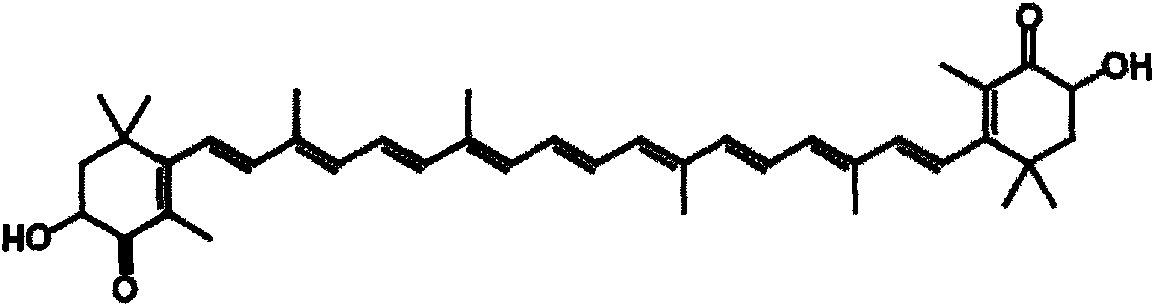

Application of astaxanthin as co-sensitizing agent in dye-sensitized solar cell

A solar cell and dye sensitization technology, which is applied in the application field of astaxanthin as a co-sensitizer in dye-sensitized solar cells, can solve the problems of affecting photoelectric conversion efficiency, low dye light-harvesting efficiency and self-aggregation, and achieves Effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of astaxanthin / CM-b co-sensitized battery. Using chloroform / absolute ethanol (4 / 6, v / v) as a solvent, prepare a mixed solution of 0.1 mM astaxanthin and 0.1 mM CM-b as a colored dye solution. The titanium dioxide photoanode was immersed in the colored dye solution, and stood at 35°C in the dark for 24 hours. Then the soaked titanium dioxide photoanode was taken out, rinsed with a dichloromethane / absolute ethanol (1 / 1, v / v) mixed solution, and dried naturally in air to obtain a dye-sensitized titanium dioxide photoanode. The dye-sensitized titanium dioxide photoanode and platinum electrode were bonded together with polyimide tape, and an electrolyte solution was injected to prepare a dye-sensitized solar cell.

Embodiment 2

[0020] Example 2: Preparation of CM-b battery for control. Using chloroform / absolute ethanol (4 / 6, v / v) as a solvent, prepare a CM-b solution with a concentration of 0.1 mM as a colored dye solution. The titanium dioxide photoanode was immersed in the colored dye solution, and stood at 35°C in the dark for 24 hours. Then the soaked titanium dioxide photoanode was taken out, rinsed with a dichloromethane / absolute ethanol (1 / 1, v / v) mixed solution, and dried naturally in air to obtain a dye-sensitized titanium dioxide photoanode. The dye-sensitized titanium dioxide photoanode and platinum electrode were bonded together with polyimide tape, and an electrolyte solution was injected to prepare a dye-sensitized solar cell.

Embodiment 3

[0021]Example 3: Photoelectric conversion efficiency test of dye-sensitized solar cells. At room temperature, under the irradiation of monochromatic light in the visible wavelength range, the monochromatic photoelectric conversion efficiency of the dye-sensitized solar cells obtained in Examples 1 and 2 was tested. The measured astaxanthin / CM-b co-sensitization battery ratio is used for the control CM-b battery. In the wavelength range of 413-670nm, the peak value is 93% and the valley value is increased from 74% to 85%. Very good The optical window of the porphyrin dye CM-b is filled, so that it has better light-harvesting ability.

[0022] At room temperature, at 100mW cm -2 Under the irradiation of a solar simulator with a power of AM1.5, the parameters of the dye-sensitized solar cells obtained in Examples 1 and 2 were tested. The measured photocurrent density of the astaxanthin / CM-b co-sensitized cell compared with the CM-b cell used for the control was from 22.58mA cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com