A method for solid-phase oxidation modification of converter steel slag

A technology of converter steel slag and solid phase oxidation, which is applied in the field of metallurgy, can solve the problem of low concentrate yield, achieve the effects of improving efficiency and income, avoiding environmental pollution and resource waste, and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] 1. Thermodynamic prediction

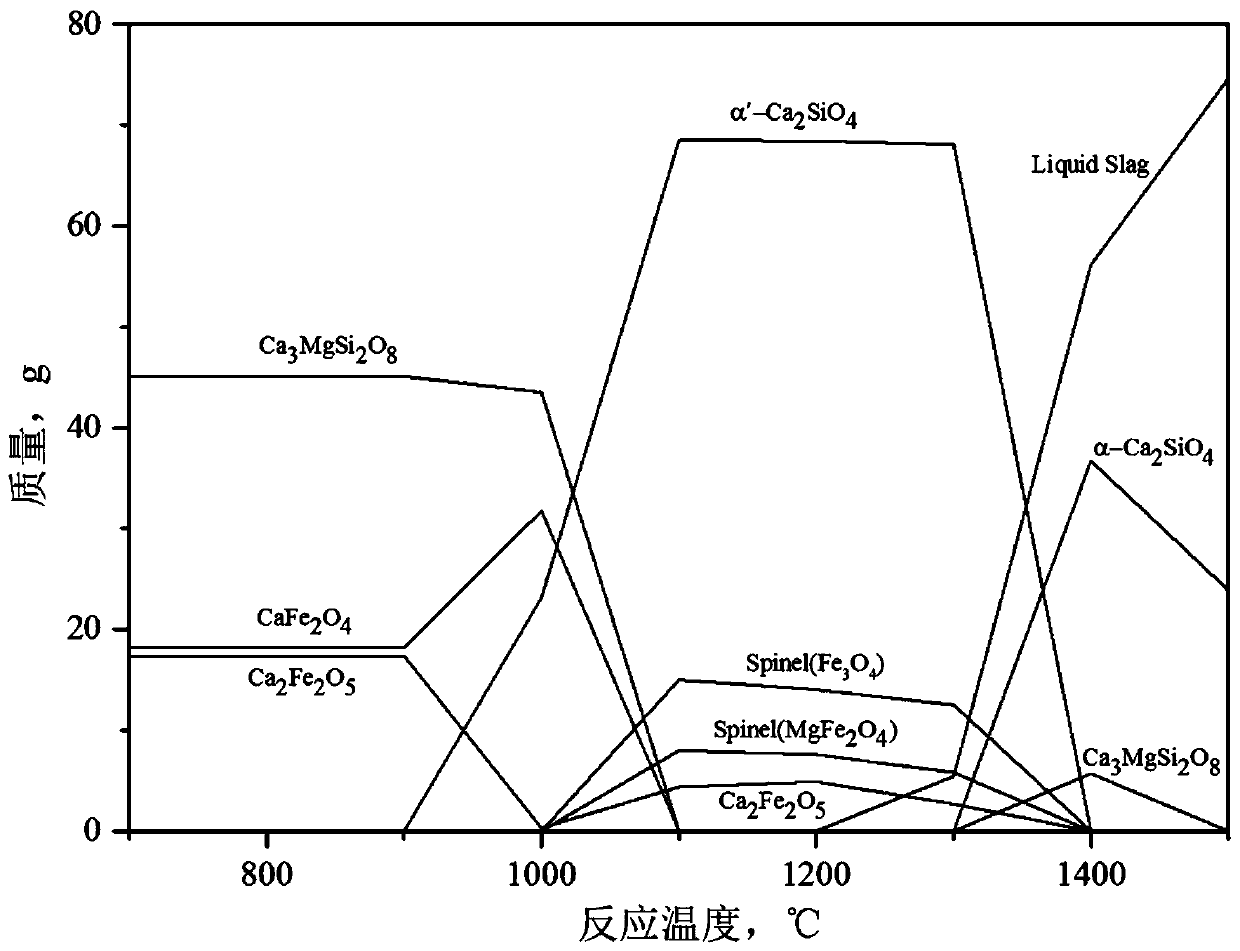

[0024] Before the experiment, the thermodynamic calculation of the solid-phase modification process of industrial steel slag was carried out ( figure 2 ), referring to the actual chemical composition and solid-phase modification process of industrial steel slag, using FactSage 7.0 to calculate the equilibrium products at different temperatures during the calcination process of steel slag powder, the main parameters of FactSage are set as follows: temperature range 700 ° C ~ 1500 ° C; The total ambient pressure is 1 atm, the oxygen partial pressure is 0.21 atm, and the calculation database is FToxid-SLAGA, FToxid-SPINA, FToxid-MeO-A, FToxid-aC2S, FToxid-Mel.

[0025] From the results of thermodynamic calculations, it can be seen that the temperature range for the formatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com