A kind of preparation method of silica microsphere-titanium dioxide composite powder pigment

A silicon dioxide and titanium dioxide technology, which is applied in chemical instruments and methods, inorganic pigment treatment, dyed polymer organic compound treatment, etc. Good dispersion, clean production process, no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

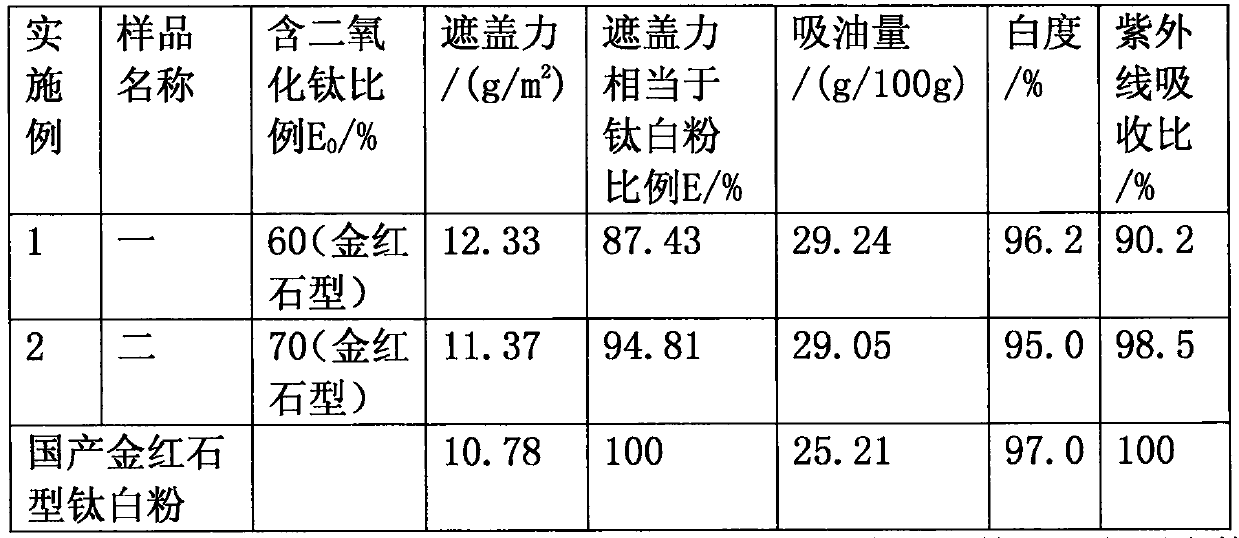

Examples

Embodiment 1

[0029] 1. Selection of raw materials:

[0030] The silica fume, the by-product of the fused zirconia production process, is the silica microsphere powder as the matrix, and its chemical composition is silica as an amorphous phase. The mass percentage of balls is 40%, the mass percentage of microspheres with a diameter of 0.5-2μm is 60%; the industrial grade metatitanic acid is used as the titanium dioxide precursor, the mass percentage of titanium dioxide in the industrial grade metatitanic acid is 55%, the water mass percentage is 43%, and the volatile matter The mass percentage of sulfur dioxide is 2%; with the polyethylene glycol of model being PEG6000 and the industrial grade sodium polyacrylate of 30% solid mass percentage as a dispersant, sodium hydroxide as an alkali treatment agent, and dilute sulfuric acid as a pH regulator;

[0031] 2. Raw material ratio and preparation process steps:

[0032] (1) Preparation of silica microsphere powder-water suspension

[0033] T...

Embodiment 2

[0047] 1. Selection of raw materials:

[0048] The silica fume, the by-product of the production process of fused zirconia, is used as the matrix, and its chemical composition is silica as an amorphous phase. The diameter of the microsphere is 0.5-3 μm, and the diameter of the microsphere is 2-3 μm. The mass percentage is 40%, the mass percentage of 0.5-2μm microspheres is 60%; the industrial grade metatitanic acid is used as the titanium dioxide precursor, the mass percentage of titanium dioxide in the metatitanic acid is 55%, the water mass percentage is 43%, and the volatile sulfur dioxide 2% by mass; the model is PEG6000 polyethylene glycol and 30% solid mass percent of industrial grade sodium polyacrylate as a dispersant, sodium hydroxide as an alkali treatment agent, and dilute sulfuric acid as a pH regulator;

[0049] 2. Raw material ratio and preparation process steps:

[0050] (1) Preparation of silica microsphere powder-water suspension

[0051] The raw materials a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com