A kind of purification method of Yersinia pestis f1vmut fusion protein

A Yersinia and fusion protein technology, applied in the field of fusion protein purification, can solve problems such as difficulty, formation of heterogeneous aggregates, and increase in purification of target protein, reducing production time and input cost, and achieving good immunogenicity. and protective, target protein loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, construction and expression of recombinant expression plasmid pET-F1Vmut

[0037] 1. Sequence optimization of the target gene

[0038] According to the F1 (AF542378.1) and V (AF074612.1) gene sequences published by GenBank, remove the base sequence corresponding to the 1-14 amino acids at the N-terminal of the F1 protein, and introduce an NdeI restriction site at the 5' end of the nucleic acid sequence , the 3' end introduces the base sequence corresponding to the 1-21 amino acids at the N-terminus of the F1 molecule and the BamHI restriction site, mutates the base encoding Cys at position 273 of the V protein into the base encoding Ser, and introduces at both ends BamHI, NotI double restriction sites, the optimized nucleotide sequence is shown in SEQ ID NO.1 (the corresponding amino acid sequence is shown in SEQ ID NO.2). Gene synthesis is carried out according to the optimized nucleotide sequence.

[0039] 2. Construction of expression vector

[0040]...

Embodiment 2

[0043] Embodiment 2, scale fermentation and purification of F1Vmut

[0044] 1. Optimization of fermentation conditions

[0045] First, optimize the key parameters of the fermentation in a 5L shake flask, resuspend the collected bacteria in proportion, analyze the supernatant and sediment by SDS-PAGE after sonication, and finally determine the fermentation conditions of the small test: induce OD 600nm Value: 0.8, induction temperature: 25°C, IPTG concentration: 50 μmol / L, induction time: 5 hours.

[0046] 2. Scale-up of fermentation

[0047] On the basis of the above conditions, the pilot scale fermentation was explored, and the final scale fermentation process of the pilot scale was determined as follows: (1) Seed activation: take a working seed and thaw it, and insert a pre-prepared 50mL primary medium ( Amp) according to the inoculation amount of 1:50, cultured at 37°C and 220r / min for 8-12 hours. Take out 20mL from the first-grade seeds and inoculate them into 1L of medi...

Embodiment 3

[0058] Embodiment 3, the immunogenicity analysis of F1Vmut

[0059] 1. SDS-PAGE analysis of recombinant antigens

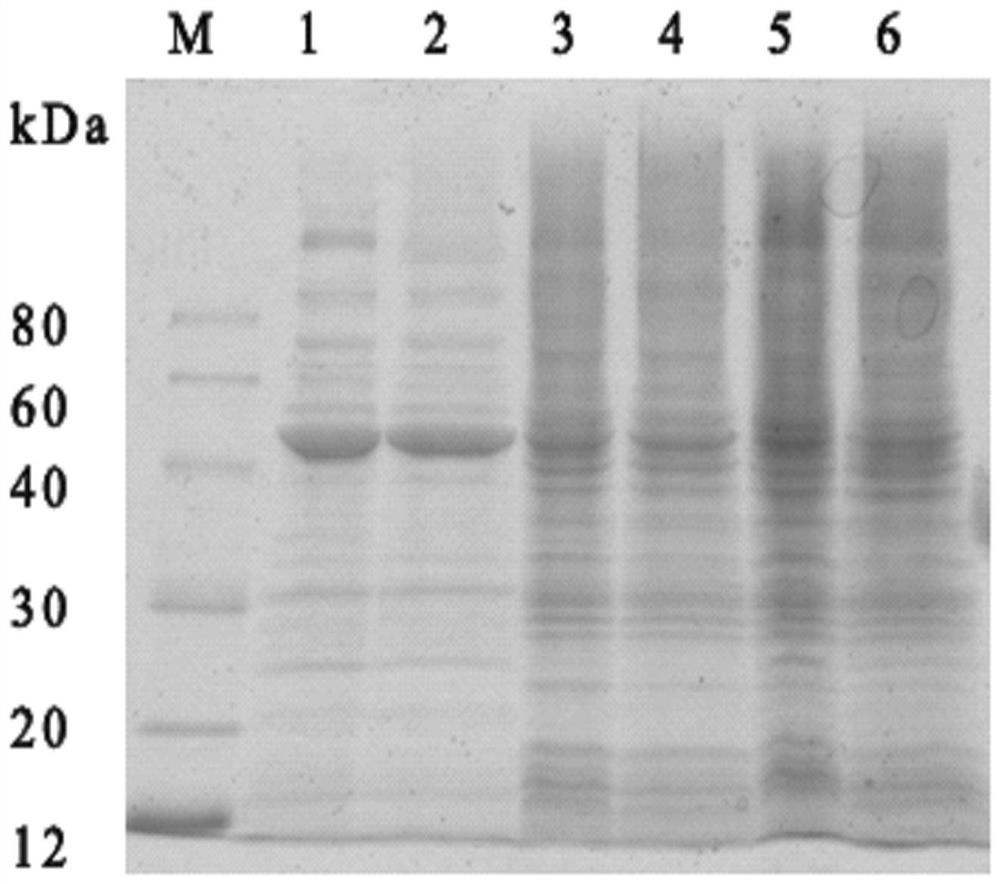

[0060] Before immunizing the mice, the F1Vmut prepared by the present invention (stored at 25°C for 1 month) was analyzed by SDS-PAGE together with the recombinant F1 antigen, V antigen and unmodified fusion protein F1-V antigen stored at -70°C. Comparative analysis by reducing and non-reducing electrophoresis ( Image 6 , 1: non-reduced F1; 2: non-reduced V; 3: non-reduced F1-V; 4: non-reduced monomer F1Vmut; 5: protein molecular weight marker; 6: reduced F1; 7: reduced V; 8: reduced 9: reduced F1Vmut), compared with F1 and F1-V, it is easy to form multimers with irregular molecular weight, and most of V finally exists in the form of dimers. The F1Vmut constructed by the present invention can stabilize exist in a single form.

[0061] 2. Immunogenicity analysis

[0062] The recombinant F1, V and unmodified recombinant F1-V fusion proteins stored in our labora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com