Biomimetic mineralization material in a polyanion modified fiber, preparation method and application

A polyanion and modified fiber technology, which is applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as difficulty in ensuring the effective concentration of local polyelectrolytes, inability to induce mineralization in fibers, and biological stimulation responses. Achieve the effects of long mineralization cycle, good biocompatibility, and enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Dissolve high-molecular-weight anionic electrolyte polyacrylic acid (molecular weight 450kDa) in 2-(N-morpholine)ethanesulfonic acid (MES) buffer to form a polyelectrolyte solution with a concentration of 10mg / mL, and use low-concentration NaOH The solution adjusts the pH of the polyelectrolyte solution to 6.

[0045] (2) 1-Ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) was dissolved in the above polyelectrolyte solution at a concentration of 10 mg / mL.

[0046] (3) N-hydroxysuccinimide (NHS) was dissolved in the polyelectrolyte solution at a concentration of 15 mg / mL.

[0047] (4) Standing at room temperature for 15 minutes to activate the carboxyl group on the long-chain polyelectrolyte to form an ester under the action of EDC and NHS.

[0048] (5) Adjust the pH value of the polyelectrolyte solution to 7.0 with a low-concentration NaOH solution.

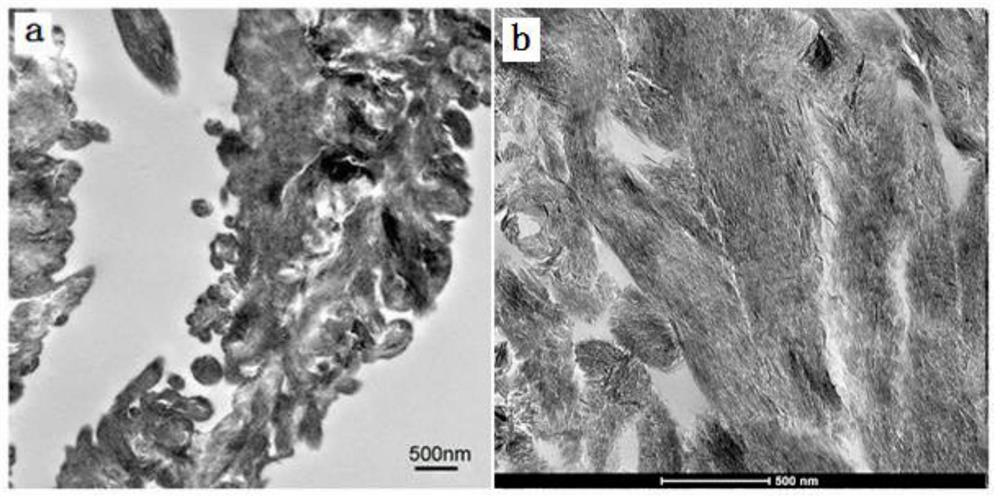

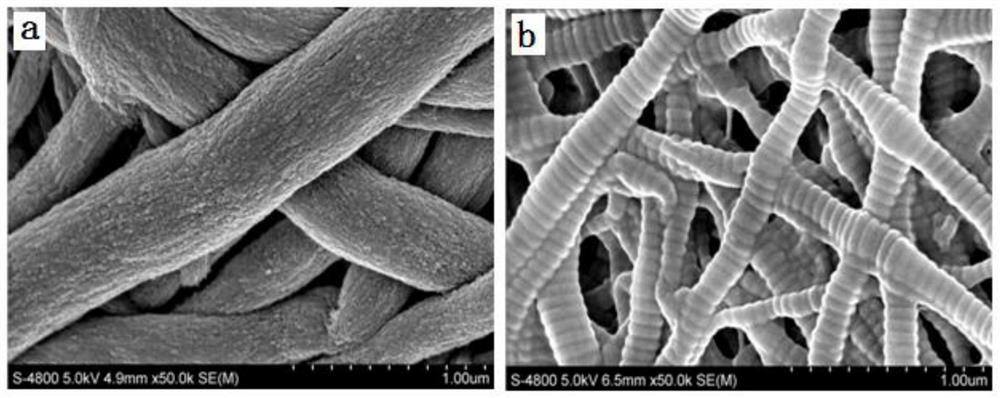

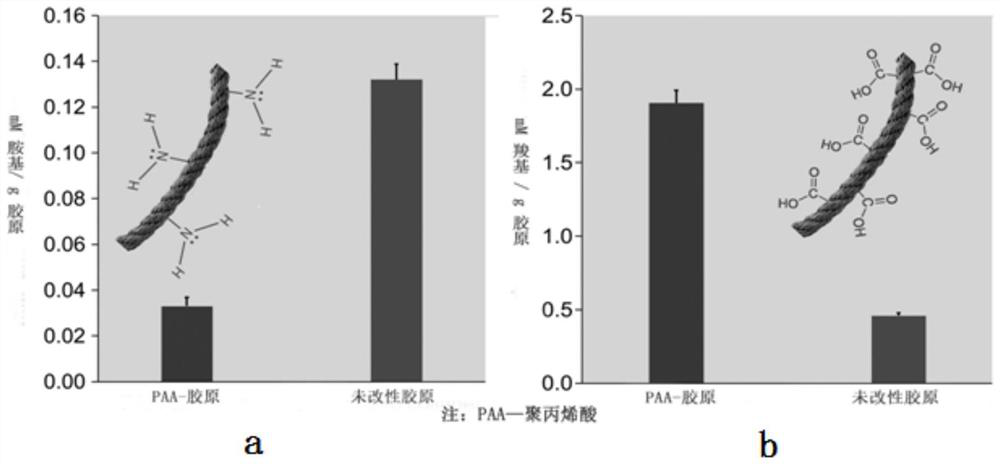

[0049] (6) Place the collagen sponge or the fully demineralized collagen matrix in the above polyelectrolyte solu...

Embodiment 2

[0062] This embodiment differs from Embodiment 1 in that:

[0063] (1) Dissolve high-molecular-weight polyaspartic acid (180kDa) in 2-(N-morpholine)ethanesulfonic acid (MES) buffer to form a polyelectrolyte solution with a concentration of 5 mg / mL, and use low-concentration NaOH Solution Adjust the pH of the polyelectrolyte solution to 6.0.

[0064] (2) Put the collagen sponge in the polyaspartic acid electrolyte solution, react at room temperature for 2 minutes so that a large number of carboxyl groups can be firmly cross-linked on the collagen molecules through covalent bonding, take out the collagen sponge, and rinse with deionized water repeatedly , 10 minutes each time, repeat 6 times. Then place it on a shaker and vibrate for 20 minutes to completely remove free polyelectrolyte molecules on the surface of the material to obtain a polyanion-modified collagen scaffold material.

Embodiment 3

[0066] This embodiment differs from Embodiment 1 in that:

[0067] (1) Dissolve high-molecular-weight polyglutamic acid (molecular weight 700kDa) in 2-(N-morpholine)ethanesulfonic acid (MES) buffer to form a polyelectrolyte solution with a concentration of 7 mg / mL, and use low-concentration NaOH Solution Adjust the pH of the polyelectrolyte solution to 6.0.

[0068] (2) Put the collagen sponge in the polyaspartic acid electrolyte solution, react at room temperature for 10 minutes so that a large number of carboxyl groups are firmly cross-linked on the collagen molecules through covalent bonding, take out the collagen sponge, and rinse with deionized water repeatedly , 10 minutes each time, repeat 6 times. Then place it on a shaker and vibrate for 20 minutes to completely remove free polyelectrolyte molecules on the surface of the material to obtain a polyanion-modified collagen scaffold material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com