Dairy product containing galactooligosaccharide and fructose and preparation method thereof

A technology of galactooligosaccharides and dairy products, which is applied in the direction of dairy products, other dairy products, bacteria used in food preparation, etc., can solve problems such as instability of galactooligosaccharides, achieve pleasant sweetness, and the process is simple and efficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

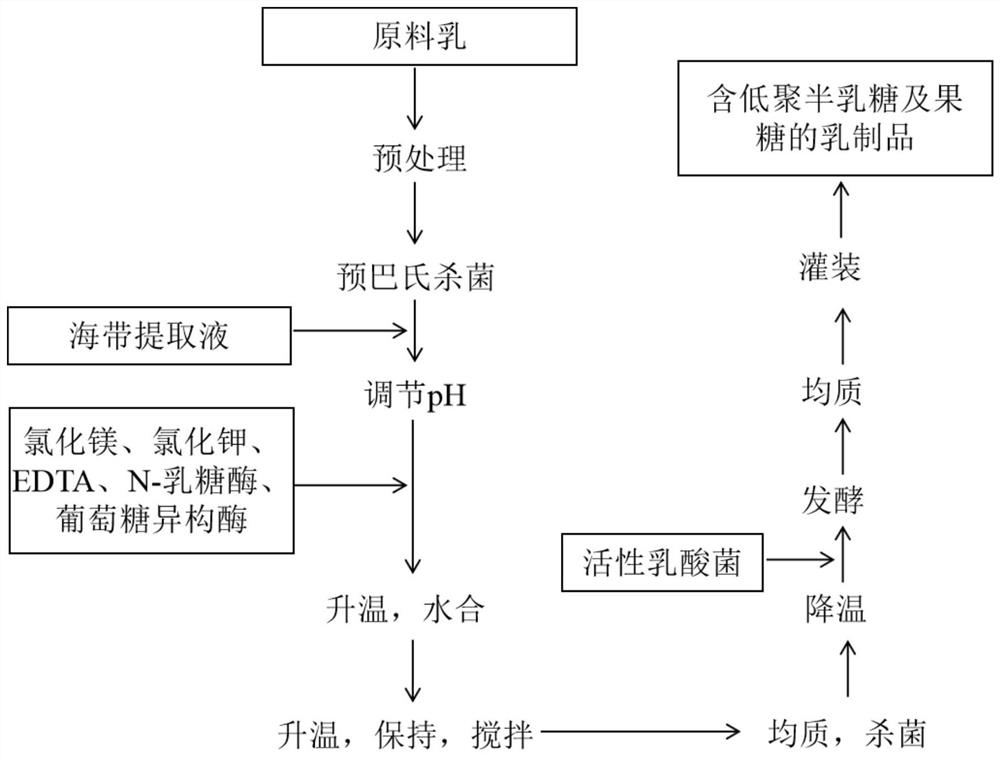

Method used

Image

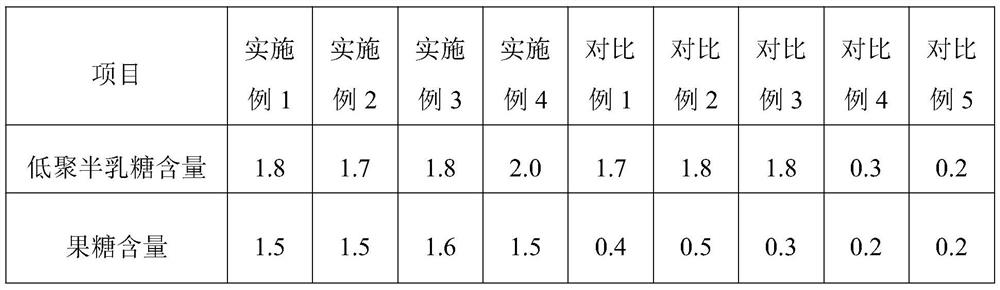

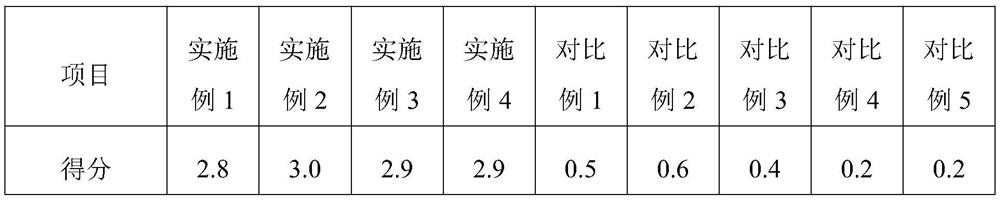

Examples

Embodiment 1

[0028] (1) Centrifuge 100 parts of fresh raw milk, then filter the raw milk with a filter membrane with a pore size of 45 nanometers at 10°C, and sterilize at 85°C for 10 seconds to obtain pre-pasteurized milk;

[0029] (2) Add 0.2 parts of kelp extract to the pre-pasteurized milk, adjust the pH to 6.9, add 0.015 parts of magnesium chloride, 0.015 parts of potassium chloride, 0.003 parts of EDTA, 0.15 parts of N-lactase and 0.08 parts of glucose isomerase , after mixing evenly, heat up to 40°C, hydrate for 100 minutes, raise the temperature to 60°C and keep for 60 minutes, and stir in a vacuum mixer for 10 minutes;

[0030] (3) Homogenize the material obtained in step (2) at a pressure of 200 bar and a temperature of 60°C, and sterilize at a temperature of 95°C for 300s;

[0031] (4) Cool the material obtained in step (3) to 40°C, add active lactic acid bacteria, the active lactic acid bacteria are 0.05 part of Lactobacillus bulgaricus and 0.1 part of Streptococcus thermophilu...

Embodiment 2

[0034] (1) Centrifuge 100 parts of fresh raw milk, then filter the raw milk with a filter membrane with a pore size of 45 nanometers at 10°C, and sterilize at 80°C for 20s to obtain pre-pasteurized milk;

[0035] (2) Add 1 part of kelp extract to the pre-pasteurized milk, adjust the pH to 6.9, add 0.05 part of magnesium chloride, 0.05 part of potassium chloride, 0.008 part of EDTA, 0.5 part of N-lactase and 0.2 part of glucose isomerase , after mixing evenly, heat up to 40°C, hydrate for 120 minutes, raise the temperature to 60°C and keep for 40 minutes, and stir in a vacuum mixer for 10 minutes;

[0036] (3) Homogenize the material obtained in step (2) at a pressure of 200 bar and a temperature of 65°C, and sterilize at a temperature of 95°C for 300s;

[0037] (4) Cool the material obtained in step (3) to 40°C, add active lactic acid bacteria, the active lactic acid bacteria are 0.1 part of Lactobacillus bulgaricus and 0.05 part of Streptococcus thermophilus, stir for 10 minu...

Embodiment 3

[0040] (1) Centrifuge 100 parts of fresh raw milk, then filter the raw milk with a filter membrane with a pore size of 60 nanometers at 5°C, and sterilize at 80°C for 20s to obtain pre-pasteurized milk;

[0041] (2) Add 0.5 part of kelp extract to the pre-pasteurized milk, adjust the pH to 6.7, add 0.01 part of magnesium chloride, 0.01 part of potassium chloride, 0.005 part of EDTA, 0.2 part of N-lactase and 0.1 part of glucose isomerase , after mixing evenly, raise the temperature to 40°C, hydrate for 120min, raise the temperature to 65°C and keep it for 60min, and stir in a vacuum mixer for 10min;

[0042] (3) Homogenize the material obtained in step (2) at a pressure of 250 bar and a temperature of 60°C, and sterilize at a temperature of 95°C for 300s;

[0043] (4) Cool the material obtained in step (3) to 40°C, add active lactic acid bacteria, the active lactic acid bacteria are 0.2 parts of Lactobacillus bulgaricus and 0.1 part of Streptococcus thermophilus, stir for 10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com