Method for corroding crystal grain morphology of surface of nickel-based high-temperature alloy

A technology of nickel-based superalloys and crystal grains, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve problems such as difficult corrosion and achieve increased corrosion depth, Prevents the formation of passivation film and satisfies observation needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

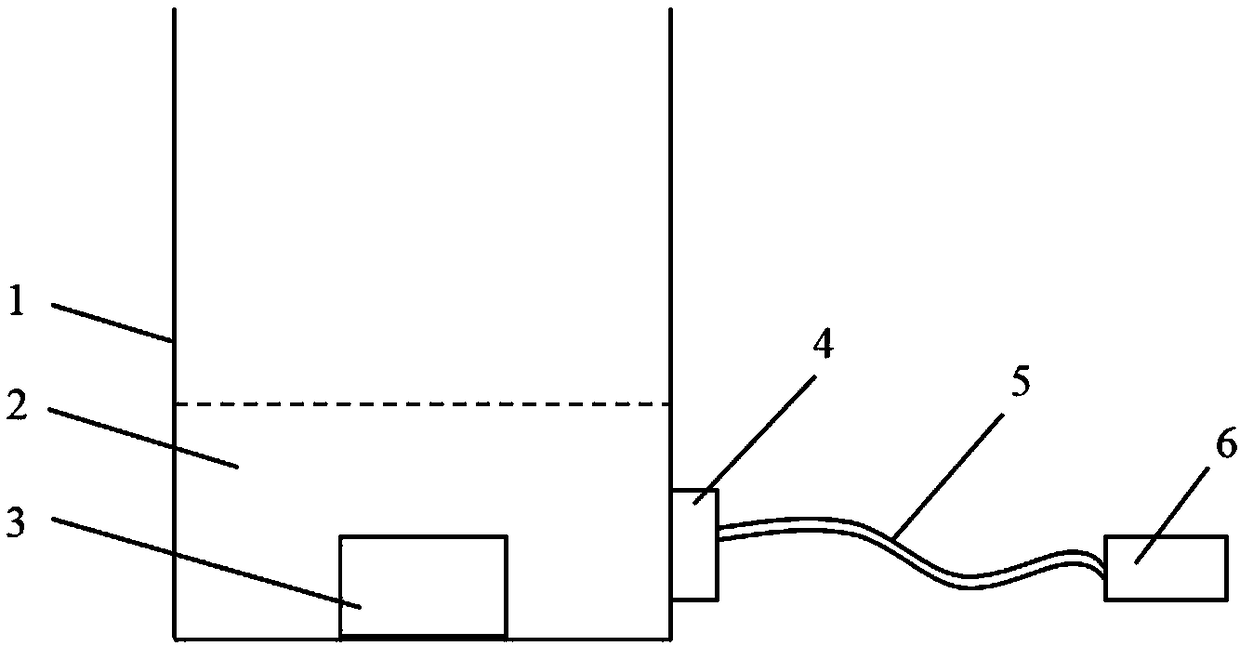

[0051] The 40,000 Hz ultrasonic combined corrosion solution was used to corrode the surface grain morphology of nickel-based superalloy (reburned superalloy). Use special glue to stick the ultrasonic transducer on the outer wall of the corrosion reaction vessel, and connect the ultrasonic transducer to the ultrasonic generating circuit board, such as figure 1 shown.

[0052] Roughly grind, finely grind, polish, clean, and dry the nickel-based superalloy samples according to conventional methods, and prepare the required corrosion solution; pour the corrosion solution into the corrosion reaction container with the ultrasonic transducer attached, turn on the ultrasonic Generator circuit switch, so that the ultrasonic transducer excites ultrasonic waves; immerse the nickel-based superalloy sample in the corrosion solution, and corrode it at a certain temperature for a certain period of time. The observation surface of the sample should be placed upwards to make the corrosion unif...

Embodiment 2

[0064] The surface grain morphology of nickel-based superalloy was corroded by 1 million Hz ultrasonic combined corrosion solution. The ultrasonic transducer is placed in the corrosive liquid and connected to the ultrasonic generating circuit board, such as Figure 5 shown.

[0065] Coat the surface of the ultrasonic transducer with a layer of anti-corrosion sealing insulating material; carry out rough grinding, fine grinding, polishing, cleaning, and drying of nickel-based superalloy samples according to conventional methods, and prepare the required corrosion solution; Put the transducer into the corrosion reaction vessel and fix it so that the direction of the ultrasonic wave is downward and keep a certain distance from the bottom of the corrosion reaction vessel; pour the corrosion solution into the corrosion reaction vessel so that the corrosion solution can immerse the ultrasonic transducer; open Switch the ultrasonic generator circuit so that the ultrasonic transducer ...

Embodiment 3

[0068] The 40,000 Hz ultrasonic combined corrosion solution was used to corrode the surface grain morphology of nickel-based superalloy. The corrosion reaction vessel adopts an ultrasonic cleaning machine, such as Image 6 shown.

[0069]Coat a layer of anti-corrosion sealing material on the inner wall of the ultrasonic cleaning machine; carry out rough grinding, fine grinding, polishing, cleaning, and drying of nickel-based superalloy samples according to conventional methods, and prepare the required corrosion solution; pour the corrosion solution Put it into the ultrasonic cleaning machine, turn on the switch of the ultrasonic cleaning machine, and excite the ultrasonic wave; immerse the nickel-based superalloy sample in the corrosion solution, and corrode it at a certain temperature for a certain period of time. The observation surface of the sample should be placed upward to make the corrosion uniform; After the end, the corroded nickel-based superalloy sample is taken o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com