Preparation method of vinyl tris(2-methoxyethoxy)silane coupling agent

A technology of methoxyethoxy and silane coupling agents, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve the problems affecting the quality of vinyl alkoxysilane products, Recycling solvents consumes a lot of energy, and the catalytic system is complicated, etc., to achieve the effects of good selectivity and stability, reduced requirements, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

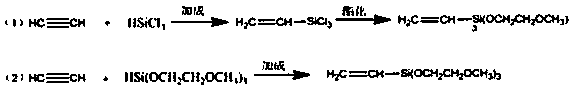

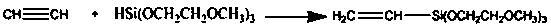

Method used

Image

Examples

Embodiment 1

[0028] Add 800 g of vinyl tris (2-methoxyethoxy) silane solvents to a self-made three-mouth long-bottomed reaction vessel with a constant pressure dropping funnel, an acetylene air duct with a bubbler, a thermometer and a condenser tube, and then add 800 g of vinyl tris (2-methoxyethoxy) silane solvent, and then add 200 ml of At a flow rate of / min, dry and purified acetylene was introduced and the temperature began to rise slowly. When the system temperature reached 45°C, 40uL of pt(0) divinyltetramethyldisiloxane solution catalyst was added, and the temperature continued to rise until the system temperature reached 85°C At this time, start to drop a total of 400g of tris(2-methoxyethoxy)hydrosilane at a uniform speed, and finish dropping after 6 hours. base) hydrosilane content is 0.32%, stop feeding acetylene and lower the temperature to obtain the reaction crude product. The reaction crude product was distilled under reduced pressure to obtain 441.2 g of vinyl tris(2-metho...

Embodiment 2

[0030] Add 800 g of vinyl tris (2-methoxyethoxy) silane solvents to a self-made three-port long-bottomed reaction vessel with a constant pressure dropping funnel, an acetylene gas guide tube with a bubbler, a thermometer and a condenser tube, and then add 800 g of vinyl tris (2-methoxyethoxy) silane solvent, and then add 170 ml At a flow rate of / min, dry and purified acetylene was introduced and the temperature began to rise slowly. When the system temperature reached 45°C, 60uL of pt(0) divinyltetramethyldisiloxane solution catalyst was added, and the temperature continued to rise until the system temperature reached 90°C At this time, a total of 400 g of tris(2-methoxyethoxy)hydrosilane was added dropwise at a uniform speed, and the drop was completed in 6.5 hours. Oxygen) hydrosilane content is 0.28%, stop feeding acetylene and lower the temperature to obtain the reaction crude product. The reaction crude product was distilled under reduced pressure to obtain 438.5 g of vi...

Embodiment 3

[0032] Add 800 g of vinyl tris (2-methoxyethoxy) silane solvents to a self-made three-port long-bottomed reaction vessel with a constant pressure dropping funnel, an acetylene gas guide tube with a bubbler, a thermometer and a condenser, and then add 800 g of vinyl tris (2-methoxyethoxy) silane solvent, and then add 220 ml At a flow rate of / min, dry and purified acetylene was introduced and the temperature began to rise slowly. When the system temperature reached 45°C, 60uL of pt(0) divinyltetramethyldisiloxane solution catalyst was added, and the temperature continued to rise until the system temperature reached 95°C At this time, a total of 400g of tris(2-methoxyethoxy)hydrosilane was added dropwise at a constant speed, and the drop was completed after 7 hours. base) hydrosilane content is 0.22%, stop feeding acetylene and lower the temperature to obtain the reaction crude product. The reaction crude product was distilled under reduced pressure to obtain 439.7 g of vinyl tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com