Method and equipment for pre-hydrocarbon pooling of catalyst

A technology for pre-hydrocarbon pool and catalyst, which is applied in the fields of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, chemical recovery, etc. The problem of poor selectivity, etc., can improve the distribution of carbon deposits, improve the catalytic activity and selectivity, and improve the reaction selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

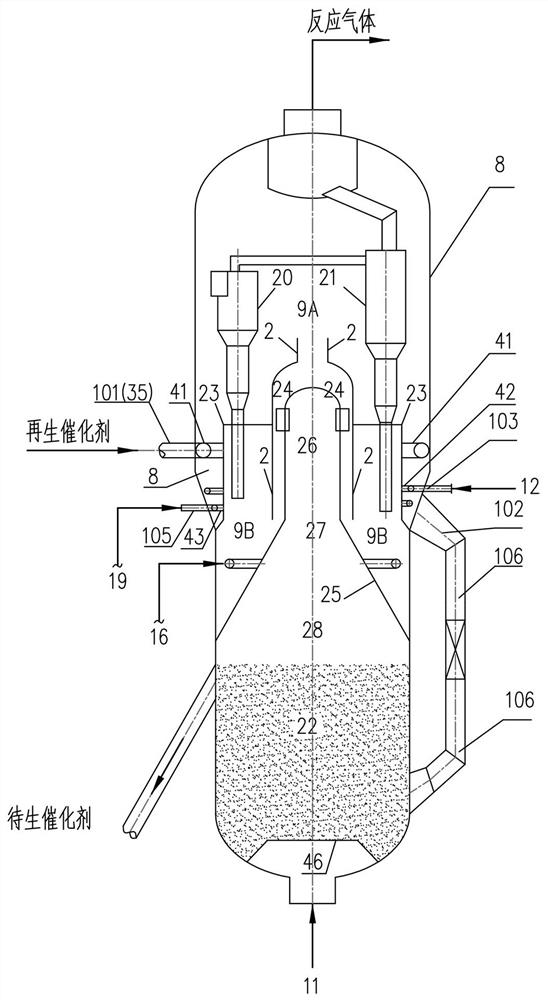

[0062] For Example 1, the oxygenate feedstock is methanol, using figure 1 In the structure shown, the methanol conversion reactor and regenerator adopt conventional operating conditions, the catalyst is SAPO-34, and the reaction gas is the activation medium. The main operating conditions of the pre-hydrocarbon pooling reactor are as follows: apparent linear velocity 0.1-0.2m / s, the reaction temperature is 460°C, and the contact time is 60-80 minutes. Here, the hydrocarbon pool active species on the regenerant is substantially restored.

[0063] Simulation calculation result shows, adopt method of the present invention and equipment thereof compared with existing MTO technology, the low carbon olefin of the present invention (C 2 = +C 3 = ) selectivity increased by 5.7 percentage points.

[0064] The main parameters and effect comparison are shown in Table 1.

[0065] Table 1

[0066] parameter Existing MTO Technology this invention Conversion reaction ...

example 2

[0068] For Example 2, the oxygenate feedstock is methanol, using figure 1 In the structure shown, the catalyst is SAPO-34, the methanol conversion reactor and the regenerator adopt conventional operating conditions, and the reaction gas is the activation medium. s, the pre-hydrocarbon pooling reaction temperature is ~460°C, and the contact time is 30-40 minutes.

[0069] Simulation results show that after adding the pre-hydrocarbon pooling facility of the present invention, compared with the existing MTO technology, the low-carbon olefins of the present invention (C 2 = +C 3 = ) selectivity increased by 3.1 percentage points.

[0070] The main parameters and effect comparison are shown in Table 2.

[0071] Table 2

[0072] parameter Existing MTO Technology this invention Conversion reaction temperature °C 480 480 Regeneration temperature ℃ 680 680 Agent / alcohol specific gravity / weight 0.23 0.23 Regenerant fixed carbon% 2.3 2.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com