Microwave dielectric ceramic with medium dielectric constant, high quality factor and near-zero tau f and preparation method thereof

A microwave dielectric ceramic, high-quality technology, applied in the field of microwave dielectric ceramic materials, can solve the problems that the quality factor cannot be improved at the same time, the temperature coefficient of resonance frequency is close to zero, etc., and achieve the effect of low production cost, good performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

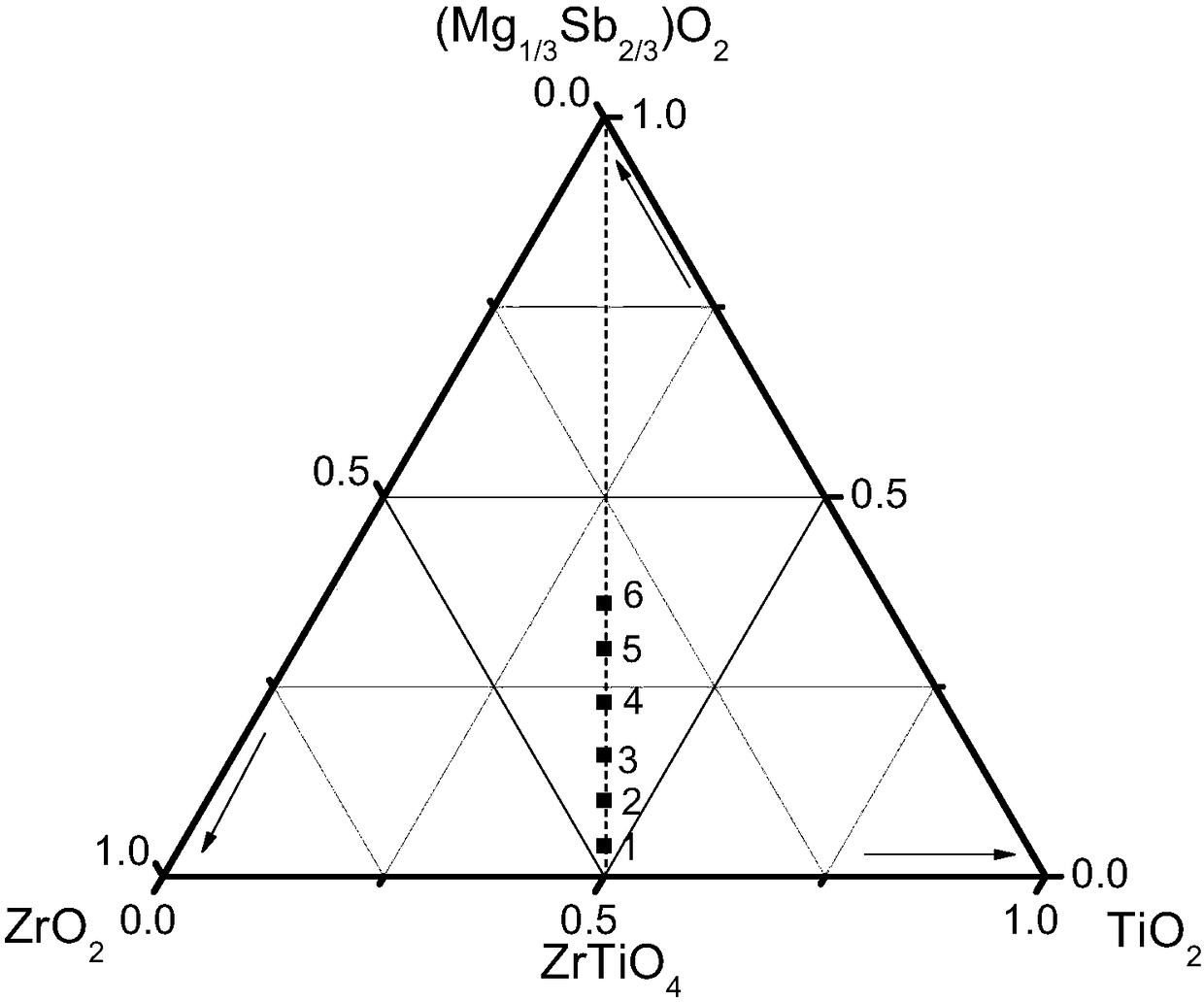

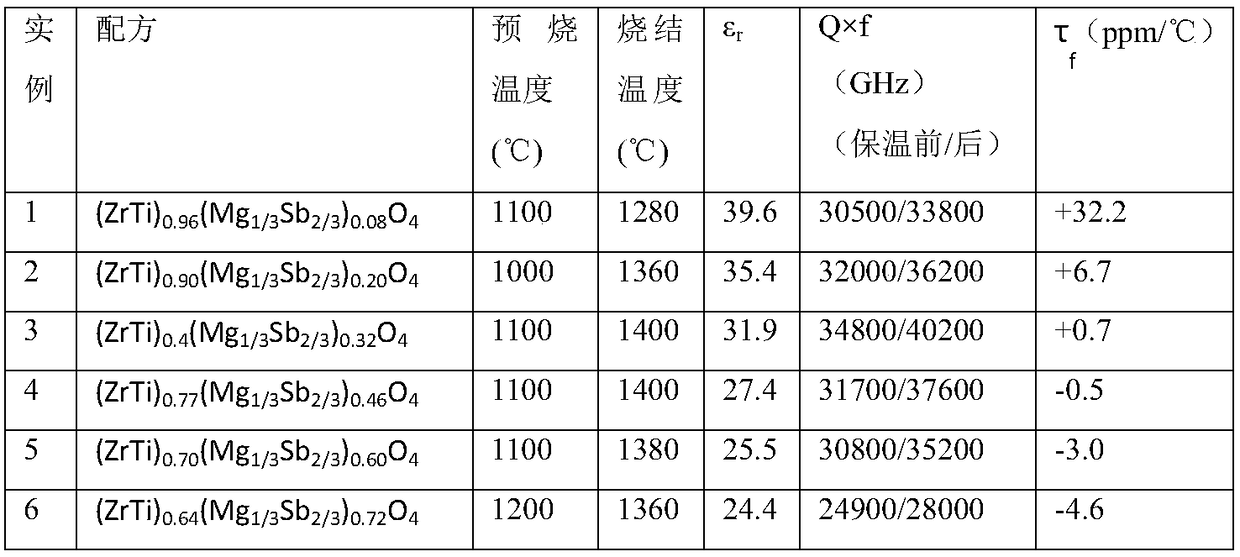

[0032] An intermediary high-quality τ f The preparation method of near-zero microwave dielectric ceramics, including:

[0033] (1) TiO 2 , (Mg 1 / 3 Sb 2 / 3 )O 2 and ZrO 2 According to (ZrTi) 1-x (Mg 1 / 3 Sb 2 / 3 ) 2x o 4 The ratio is mixed to obtain the mixed raw material, wherein, 0.10≤x≤0.36;

[0034] (2) Carry out wet ball milling for the first time, drying for the first time, pre-calcination, wet ball milling for the second time and drying for the second time successively to the mixed raw materials to obtain the first mixture, wherein the pre-calcination temperature is 1000 ℃~1200℃, pre-burning time is 1h~3h;

[0035] (3) After adding a binder to the first mixture, press it with a powder tablet press to obtain a green body, and sinter the green body at 1360° C. to 1400° C. for 2 hours to 4 hours to obtain a microwave dielectric ceramic.

[0036] The molding pressure of the powder tablet press is 50MPa-100MPa, the binder is polyvinyl alcohol with a mass fraction of ...

Embodiment 1

[0038] An intermediary high-quality τ f The preparation method of near-zero microwave dielectric ceramics, including:

[0039] (1) TiO 2 , (Mg 1 / 3 Sb 2 / 3 )O 2 and ZrO 2 According to (ZrTi) 0.96 (Mg 1 / 3 Sb 2 / 3 ) 0.08 o 4 The ratio is mixed to obtain the mixed raw material,

[0040] (2) Carry out wet ball milling for the first time, drying for the first time, pre-calcination, wet ball milling for the second time and drying for the second time to the mixed raw materials successively to obtain the first mixture, wherein the pre-calcination temperature is 1100 ℃, the pre-burning time is 2h;

[0041] (3) After adding a binder to the first mixture, press it with a powder tablet press to obtain a green body, and sinter the green body at 1280° C. for 4 hours to obtain a microwave dielectric ceramic.

[0042] The molding pressure of the powder tablet press is 50 MPa, the binder is polyvinyl alcohol with a mass fraction of 8%, and the binder is 5% of the mass of the first mix...

Embodiment 2

[0044] An intermediary high-quality τ f The preparation method of near-zero microwave dielectric ceramics, including:

[0045] (1) TiO 2 , (Mg 1 / 3 Sb 2 / 3 )O 2 and ZrO 2 According to (ZrTi) 0.90 (Mg 1 / 3 Sb 2 / 3 ) 0.20 o 4 The ratio is mixed to obtain the mixed raw material,

[0046] (2) Carry out wet ball milling for the first time, drying for the first time, pre-calcination, wet ball milling for the second time and drying for the second time successively to the mixed raw materials to obtain the first mixture, wherein the pre-calcination temperature is 1000 ℃, the pre-burning time is 3h;

[0047] (3) After adding a binder to the first mixture, press it with a powder tablet press to obtain a green body, and sinter the green body at 1360° C. for 3 hours to obtain a microwave dielectric ceramic.

[0048] The molding pressure of the powder tablet press is 80 MPa, the binder is polyvinyl alcohol with a mass fraction of 10%, and the binder is 5.5% of the mass of the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com