Method for eliminating CO in restricted space through ultrasonic atomizing spray of chemical absorbing solution

A chemical absorption, ultrasonic atomization technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of unsatisfactory purification effect, harsh reaction conditions, complicated operation, etc., to increase operability and portability. , The effect of reducing CO concentration and prolonging active time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

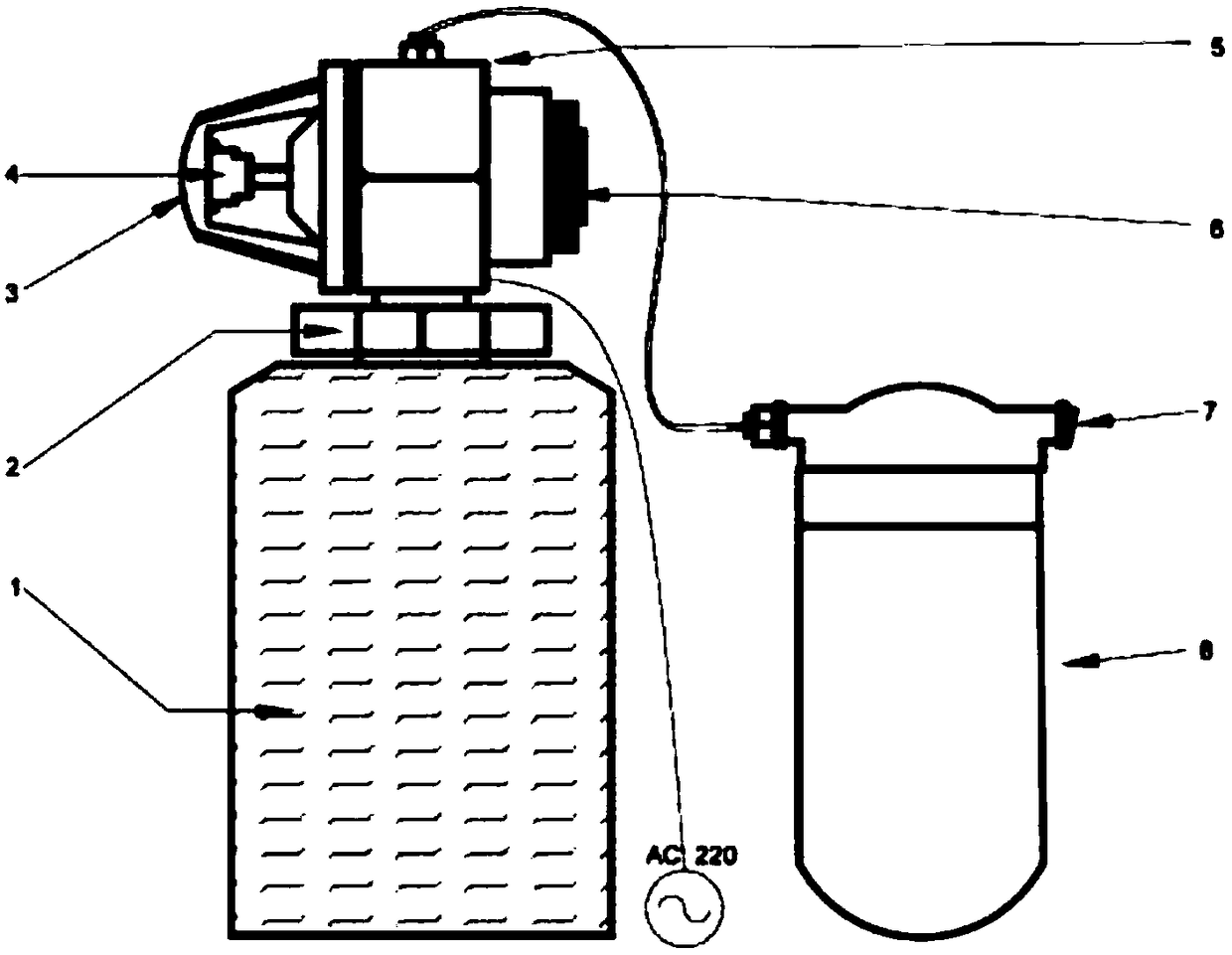

[0019] The method of ultrasonic atomization and spraying of chemical absorption liquid to eliminate CO in a confined space, using atomization absorption method to remove CO: the combination of ultrasonic atomization device and absorption method with chemical reaction, that is, chemical absorption liquid, has made a breakthrough. The traditional absorption method has the shortcomings of bulky equipment and poor operability, which solves the problem of reducing CO concentration efficiently and rapidly in confined spaces, and ensures the safety of personnel. Specific steps are as follows:

[0020] (1) The chemical absorption liquid storage tank 1 is connected with the ultrasonic atomization device;

[0021] (2) Start the ultrasonic atomization spraying device in a confined space, first press the air pump switch 7 to start the air pump 8, so that the absorption liquid in the chemical absorption liquid storage tank 1 is pumped into the impact resonance cavity 5; compressed air also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com