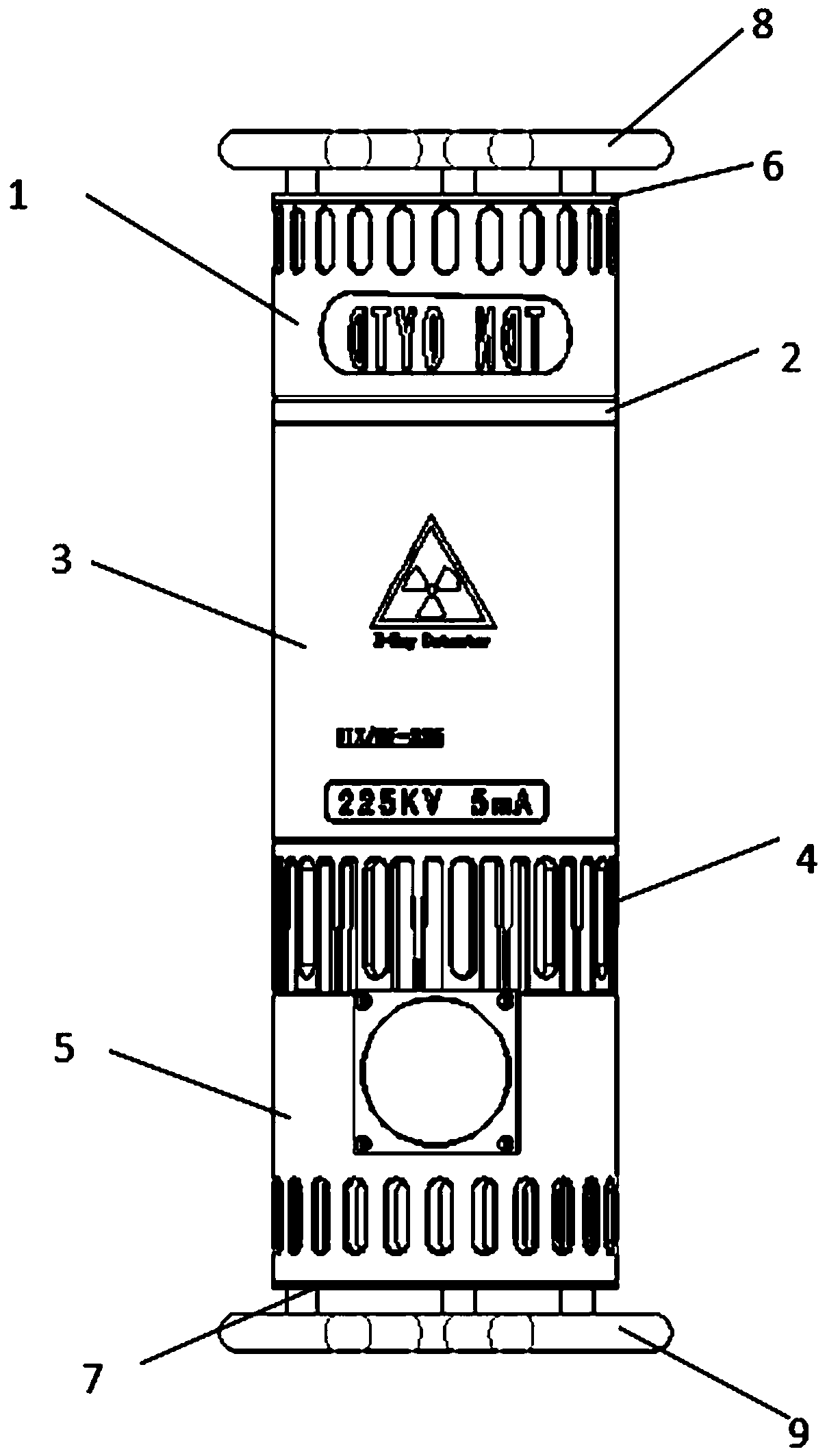

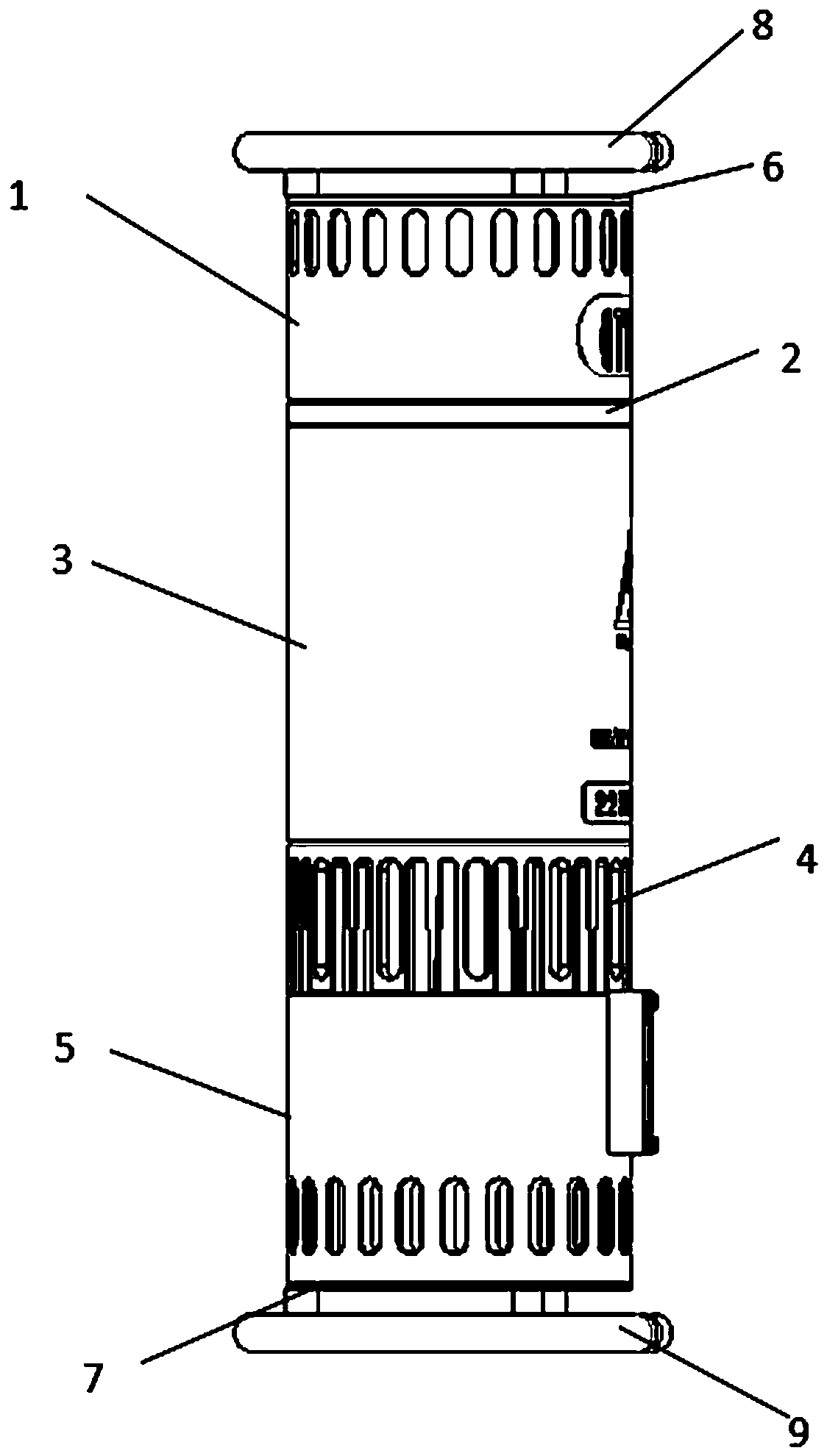

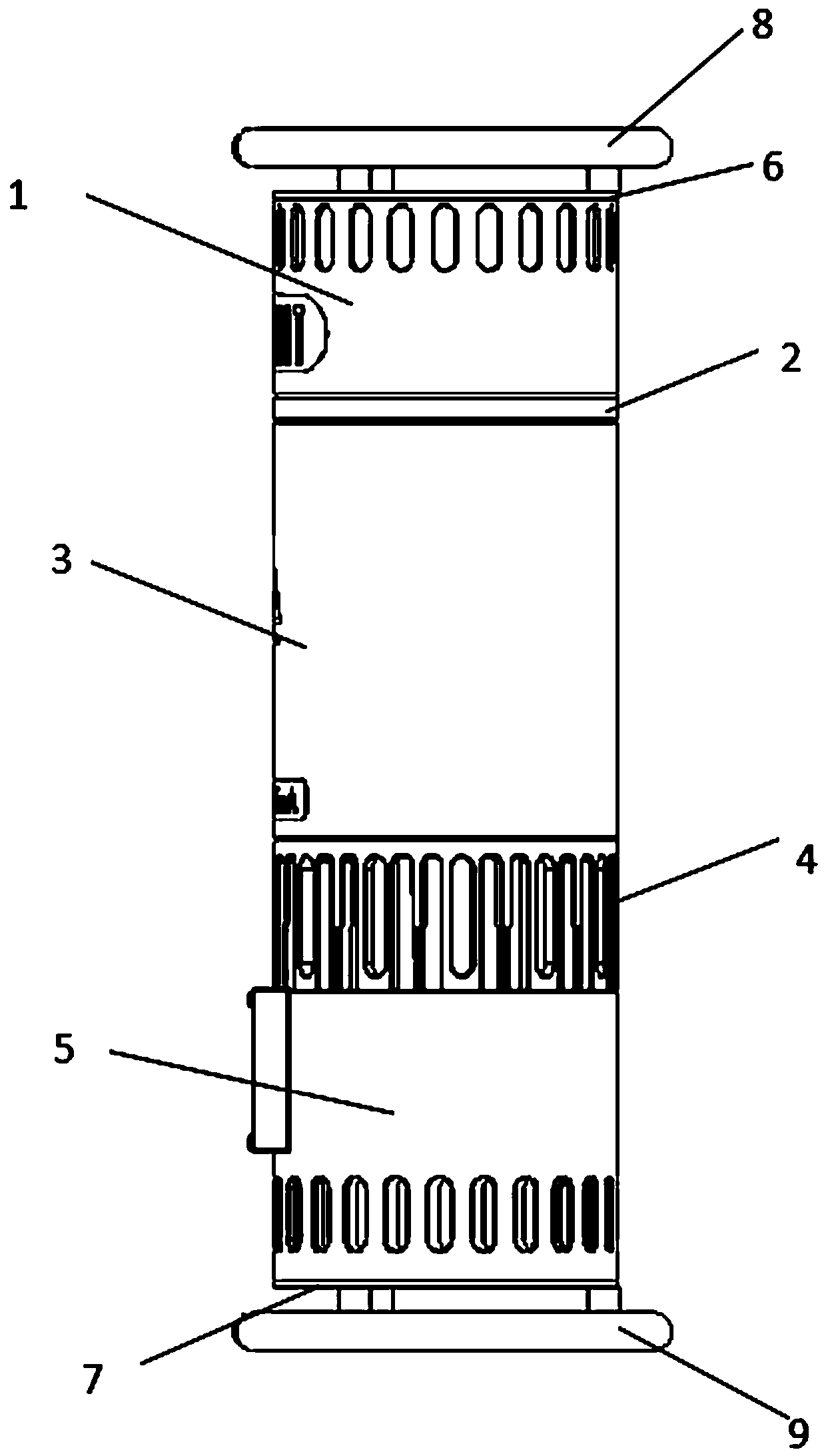

Wireless integrated X ray flaw detector

An X-ray and flaw detector technology, which is used in material analysis using radiation, material analysis using wave/particle radiation, measuring devices, etc., can solve problems such as instability, laborious handling, interference, etc., to reduce weight and avoid attenuation. , the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0048] The wireless integrated X-ray flaw detector of the present invention includes two parts: a controller and a generator. The controller is a PDA that uses a PLC control system to control the generator through a touch screen, and adjusts kilovolts, time, and milliamps through the touch screen, and has a built-in 24V battery; the controller displays: power supply voltage, generator pressure, generator temperature, and real-time exposure Time, exposure real-time voltage, exposure real-time mA, total device startup time, total device exposure time, total device exposure times, total device startup times, status (preparation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com