Carbon structure film and graphene additive solid-liquid composite anti-friction and anti-abrasion method

A solid-liquid composite, graphene technology, used in additives, petroleum industry, lubricating compositions, etc., can solve the problems of limited life and limited film, achieve lower friction coefficient and wear rate, excellent friction and wear performance, and improve service life. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take high-polished stainless steel sheets or steel balls, go through routine cleaning: degreasing, derusting, drying and put them into a vacuum chamber;

[0031] When the vacuum chamber vacuum reaches 1×10 -4 Start coating at this time, clean with argon ion bombardment, argon controlled at 3-8 Pa, bias voltage 800-1000V, conduction ratio 0.2-0.7, frequency 15-50KHz, clean for 10-30 minutes;

[0032] In-situ nitriding with nitrogen, nitrogen controlled at 10-30 Pa, bias voltage 800-1500V, conduction ratio 0.2-0.7, frequency 15-50KHz, cleaning for 30-80 minutes;

[0033] Adjust pulse bias to 800-1000 V, conduction ratio 0.5-0.8, frequency 30-50 KHz, methane gas pressure at 15-18 Pa, methane-hydrogen pressure ratio 1:1-1:3 adjustable, preparation Fullerene carbon film, time 2-4 hours; test results film hardness 18-30GPa, thickness 1-2 microns, surface finish 0.1-0.2nm.

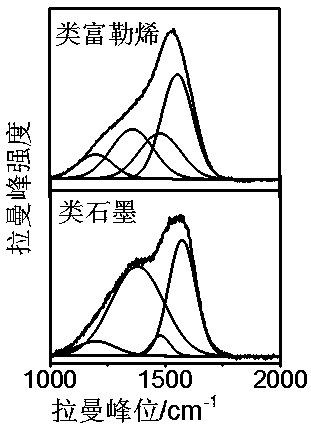

[0034] Such as figure 1 As shown, the typical Raman spectrum of fullerene-like carbon films includes a...

Embodiment 2

[0036] Take high-polished stainless steel sheets or steel balls, go through routine cleaning: degreasing, derusting, drying and put them into a vacuum chamber;

[0037] When the vacuum chamber vacuum reaches 1×10 -4 Start coating at this time, clean with argon ion bombardment, argon controlled at 3-8 Pa, bias voltage 800-1000V, conduction ratio 0.2-0.7, frequency 15-50KHz, clean for 10-30 minutes;

[0038] In-situ nitriding with nitrogen, nitrogen controlled at 10-30 Pa, bias voltage 800-1500V, conduction ratio 0.2-0.7, frequency 15-50KHz, cleaning for 30-80 minutes;

[0039] Adjust pulse bias voltage to 800-1000 V, conduction ratio 0.5-0.8, frequency 30-50 KHz, methane gas pressure at 15-18 Pa, methane-hydrogen pressure ratio 1:0-1:1 adjustable, using auxiliary Power supply heating is to control the substrate temperature at 150-350°C, and prepare graphite-like carbon film for 2-4 hours; the test results show that the film has a hardness of 8-15GPa, a thickness of 1-2 microns...

Embodiment 3

[0042] Take high-polished stainless steel sheets or steel balls, go through routine cleaning: degreasing, derusting, drying and put them into a vacuum chamber;

[0043] When the vacuum chamber vacuum reaches 1×10 -4 Start coating at this time, clean with argon ion bombardment, argon controlled at 3-8 Pa, bias voltage 800-1000V, conduction ratio 0.2-0.7, frequency 15-50KHz, clean for 10-30 minutes;

[0044] In-situ nitriding with nitrogen, nitrogen controlled at 10-30 Pa, bias voltage 800-1500V, conduction ratio 0.2-0.7, frequency 15-50KHz, cleaning for 30-80 minutes;

[0045] Adjust pulse bias voltage to 1200-1500V, conduction ratio 0.5-0.8, frequency 80-150 KHz, methane gas pressure at 15-18 Pa, methane-hydrogen pressure ratio 1:1-1:3 adjustable, preparation Onion carbon film, time 2-4 hours; test results film hardness 25-32GPa, thickness 0.8-1.8 microns, surface finish 0.1-0.2nm.

[0046] Such as figure 2 As shown, the typical Raman spectrum of onion carbon film includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com