Phase change heat storage light porous ceramic tile

A phase change heat storage and ceramic brick technology, which is applied in the field of building insulation, can solve the problems of low porosity, low thermal conductivity, and poor thermal insulation effect of thermal insulation ceramic bricks, and achieves light weight, good thermal insulation effect, and improved porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

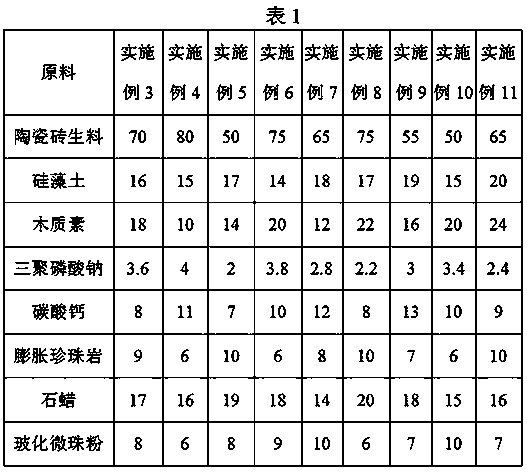

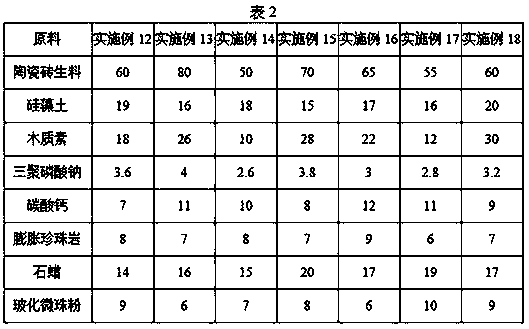

[0018] A light porous ceramic brick for phase change heat storage, prepared from the following raw materials in parts by weight: 50-80 parts of ceramic brick raw material, 14-20 parts of diatomite, 10-30 parts of lignin, sodium tripolyphosphate 2-4 parts, 7-13 parts of calcium carbonate, 6-10 parts of expanded perlite, 14-20 parts of paraffin wax, 6-10 parts of vitrified microbead powder;

[0019] Wherein, the parts by weight of ceramic tile raw materials are: SiO 2 63-73 parts, Al 2 o 3 8-16 parts, CaO1.0-2.0 parts, MgO2-4 parts, Na 2 O 5-6 parts, the particle size of expanded perlite is 5-8mm.

[0020] The preparation method of the above-mentioned phase change heat storage lightweight porous ceramic brick comprises the following steps:

[0021] (1) Mix the above-mentioned expanded perlite and melted paraffin evenly, and then heat it in a water bath at 60-70°C for 1-2 hours with vacuum stirring and adsorption, and then cool to obtain a phase change material;

[0022] (...

Embodiment 2

[0025] A lightweight porous ceramic brick for phase-change heat storage, prepared from the following raw materials in parts by weight: 65 parts of ceramic brick raw material, 17 parts of diatomite, 20 parts of lignin, 3 parts of sodium tripolyphosphate, and 10 parts of calcium carbonate 8 parts, 8 parts of expanded perlite, 17 parts of paraffin, 8 parts of vitrified microbead powder;

[0026] Wherein, the parts by weight of ceramic tile raw materials are: SiO 2 68 copies, Al 2 o 3 12 parts, 1.5 parts of CaO, 3 parts of MgO, Na 2 O5.5 parts, the particle size of expanded perlite is 6.5mm.

[0027] The preparation method of the above-mentioned phase change heat storage lightweight porous ceramic brick comprises the following steps:

[0028] (1) After mixing the expanded perlite in the above parts by weight with the melted paraffin evenly, heat it in a water bath at 65°C for 1.5 hours with vacuum stirring and adsorption, and cool it down to obtain a phase change material; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com