Self-anchorage cable bent tower driving cross brace arranging method

A self-anchored, cross-braced technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as high safety risks, complicated procedures, and insufficient operation convenience, so as to ensure project quality, simplify construction steps, Improve the effect of structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

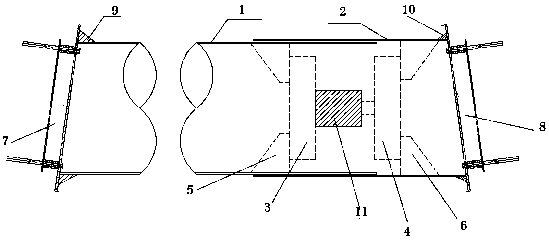

[0025] see image 3 , the invention discloses a method for setting the active cross brace of a self-anchored cable tower, which includes the following steps:

[0026] 1) Process the brace body; the brace body includes a brace steel pipe 1, a brace steel pipe load-bearing beam 3 and a first corbel 5, one end of the brace steel pipe 1 is a fixed end, the other end is a force end, the The supporting steel pipe load-bearing beam 3 is welded to the inside of the force end of the horizontal supporting steel pipe 1 through the first corbel 5;

[0027] 2) Process the steel casing; first, set the steel casing load-bearing beam 4 and the second corbel 6 inside the steel casing 2, and the back of the steel casing load-bearing beam 4 passes through the second corbel 6 and the steel casing 2 Welding and fixing; then open a reserved hole about 50cm*50cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com