Full-hydraulic crawler-type self-propelled trestle and construction method thereof

A crawler-type, full-hydraulic technology, used in pedestrian overpasses, bridges, bridge forms, etc., can solve problems such as large safety hazards, complicated construction processes, and the inability of simple trestle bridges to travel automatically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

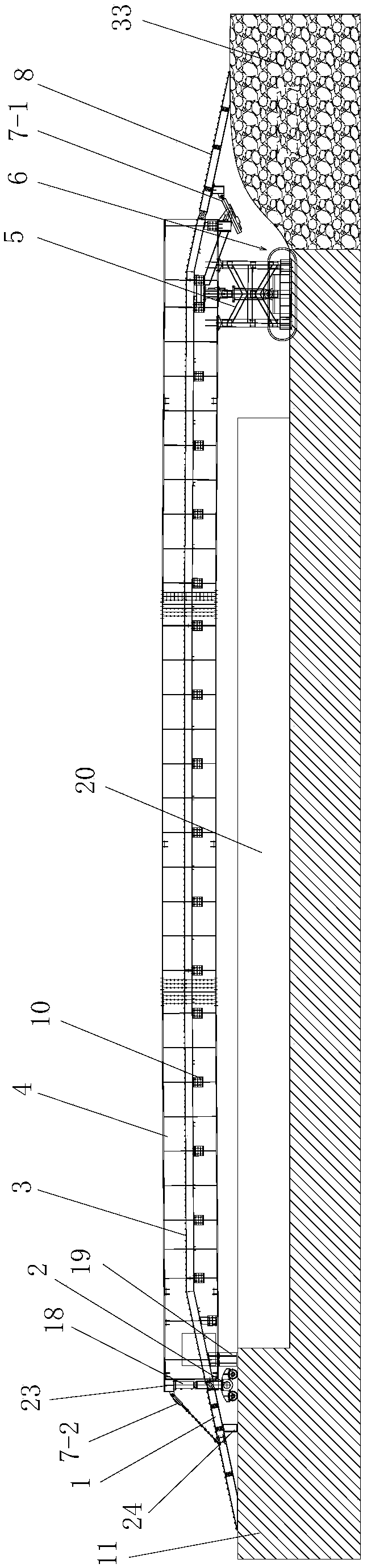

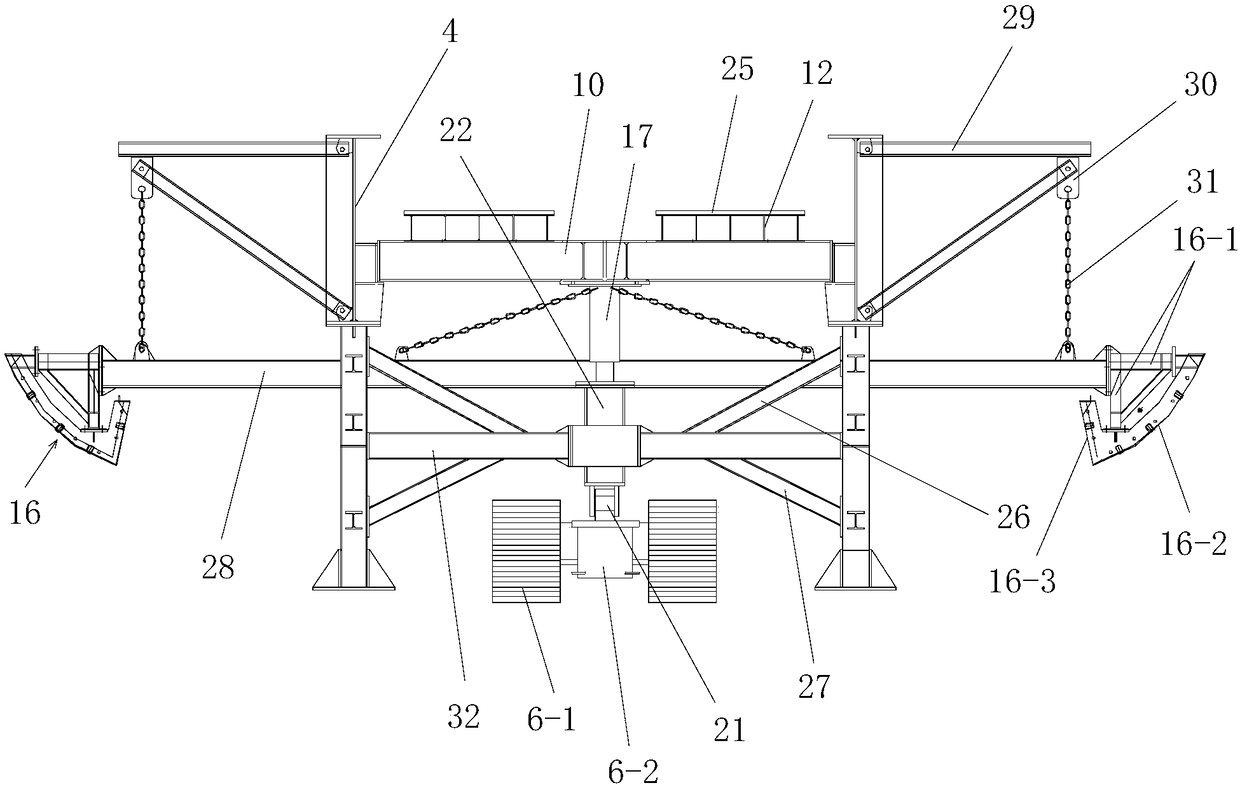

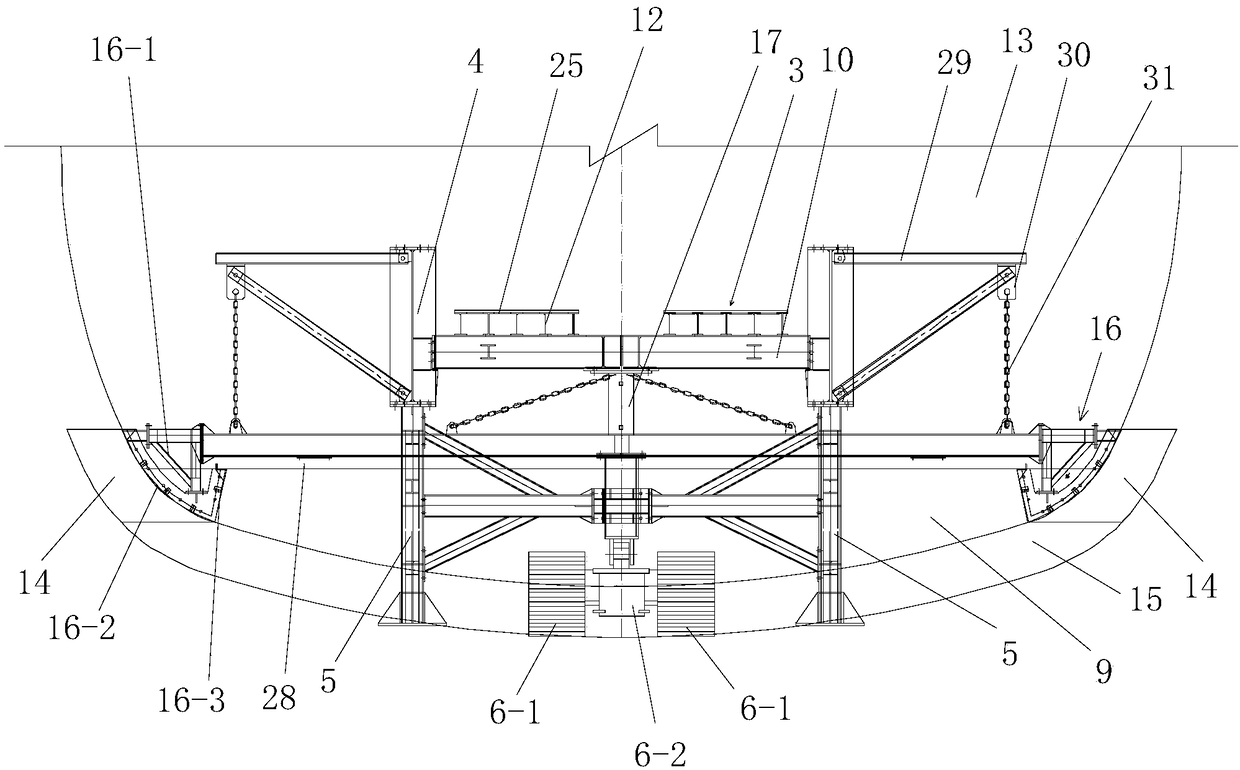

[0098] Such as figure 1 , figure 2 and image 3 A kind of full-hydraulic crawler-type self-propelled trestle bridge shown comprises a main bridge arranged along the length direction of the constructed tunnel 13, a front approach bridge 8 arranged in front of the main bridge and hinged with the front end of the main bridge and arranged in the tunnel 13. The rear approach bridge 1 directly behind the main bridge and hinged with the rear end of the main bridge also includes two symmetrical layouts on the left and right and the backfill layer 9 on the inverted arch 15 of the tunnel and the low side wall 14 of the constructed tunnel 13 The low side wall and inverted arch backfill construction formwork 16 for forming construction, the two low side walls and the inverted arch backfill construction formwork 16 are symmetrically arranged on the left and right sides of the main bridge and the two are arranged on the same horizontal plane; The tunnel secondary lining of the constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com