Preparation device and preparation method of composite powder for 3D printing

A composite powder and 3D printing technology, which is applied in the field of powder metallurgy, can solve problems such as high cost, uneven composition of composite powder, complex equipment structure, etc., and achieve the effect of uniform composition, uniform composition of composite powder, and simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

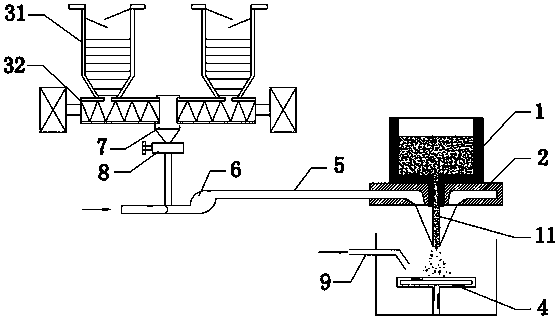

[0045] Such as Figure 1~2 As shown, a preparation device for composite powder for 3D printing is provided, which includes a supply device 1 for liquid metal raw materials, a spray table 2 and at least one feeding device. In the injection through hole, the injection tube 11 of the supply device 1 is embedded in the injection through hole. The position corresponding to the outlet of the injection tube 11 is provided with a rotating water cooling table 4 for cooling the crushed liquid metal. The end of the injection tube 11 is a nozzle.

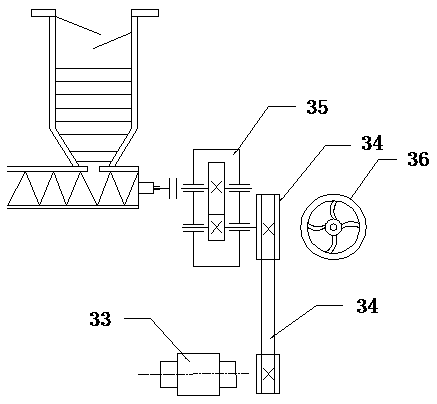

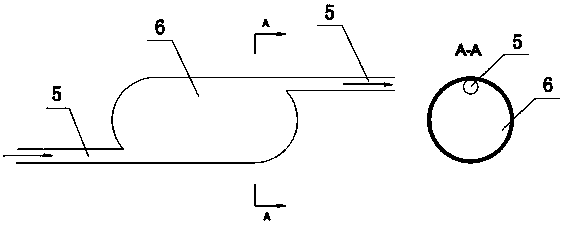

[0046] In order to make the finally obtained powder a composite powder, it is necessary to add powder materials to the metal raw material ejected from the supply device 1, so the above-mentioned preparation device also includes a gas material delivery pipe 5 with an inert gas inside, and the gas material delivery After passing through the feeding device, the end of the tube 5 is connected to the spray table 2. In this way, the powder material c...

Embodiment 2

[0060] Provide a kind of preparation method of composite powder for 3D printing, adopt the equipment of embodiment 1, and cooperate gas atomization method and injection molding technology, include:

[0061] A supply device for liquid metal raw materials is provided, and a spray pipe is arranged on the supply device;

[0062] Set up a spray table matching the supply device, and the spray pipe is embedded in the spray table;

[0063] Provide a feeding device for providing powder materials;

[0064] A gas mixing device is installed between the feeding device and the injection table. The gas mixing device has an inert gas feeding channel. The powder material provided by the feeding device can be mixed with the inert gas to form a suspension evenly after passing through the gas mixing device. Send it into the spray table to crush the liquid metal droplets sprayed from the spray tube;

[0065] A rotating water cooling table for cooling the crushed liquid metal is arranged at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com