Optical substrate, substrate for semiconductor light emitting element, and semiconductor light emitting element

A technology for optical substrates and light-emitting components, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as reduced luminous efficiency, reduced external quantum efficiency, and reduced internal quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

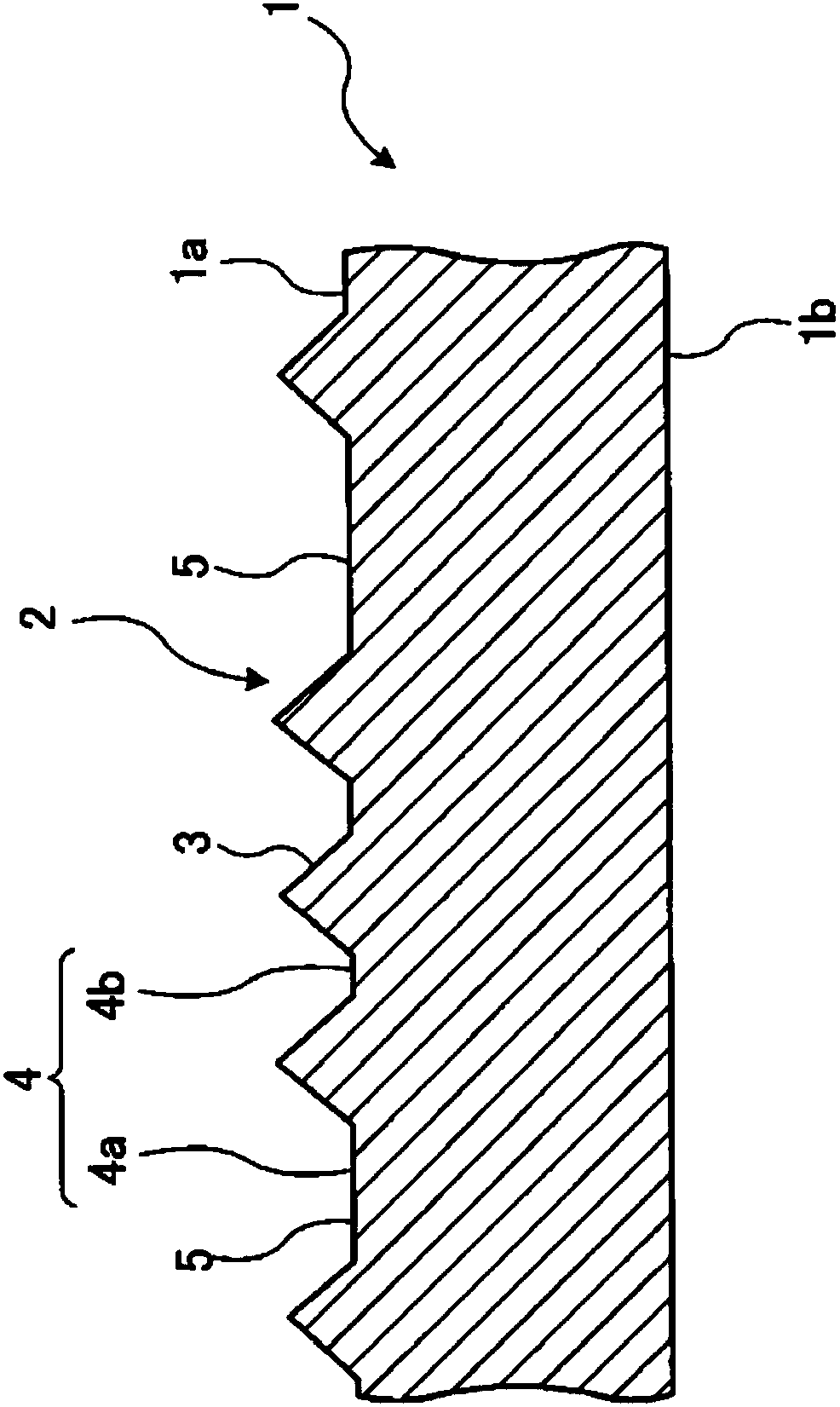

[0423] First, a substrate (optical base material) for LED is produced. The pattern of the LED substrate is made using nano-processed sheets. The nano-processed sheet will be described later. Prepare a 2-inch single-sided mirror c-plane sapphire and wash it. Next, the sapphire was placed on a hot plate at 120°C. Next, the nano-processed sheet was bonded to the sapphire using a lamination roll heated to 120°C. The bonding was performed at a line speed of 50 mm / sec under a pressure of 0.5 MPa. The sapphire to which the nano-processed sheet is laminated is irradiated with ultraviolet rays through the sapphire. Ultraviolet rays are irradiated by a UV-LED light source with a wavelength of 365nm, so the cumulative light quantity becomes 1500mJ / cm 2 Way to set. Next, the nano-processed sheet and sapphire were sandwiched by two parallel flat plates heated to 120°C. The clamping pressure is 0.3 MPa, and the time is 10 seconds. Then, it was cooled to room temperature by air cooling...

Embodiment 4

[0459] On the C-plane main surface of a 2-inch diameter sapphire single crystal substrate with a single-sided mirror-finished C-plane as the main surface, as in Example 1, the dry film resist using the nano-processed sheet was pressed In the plate printing method, a dry film resist layer formed with a convex mask pattern is formed.

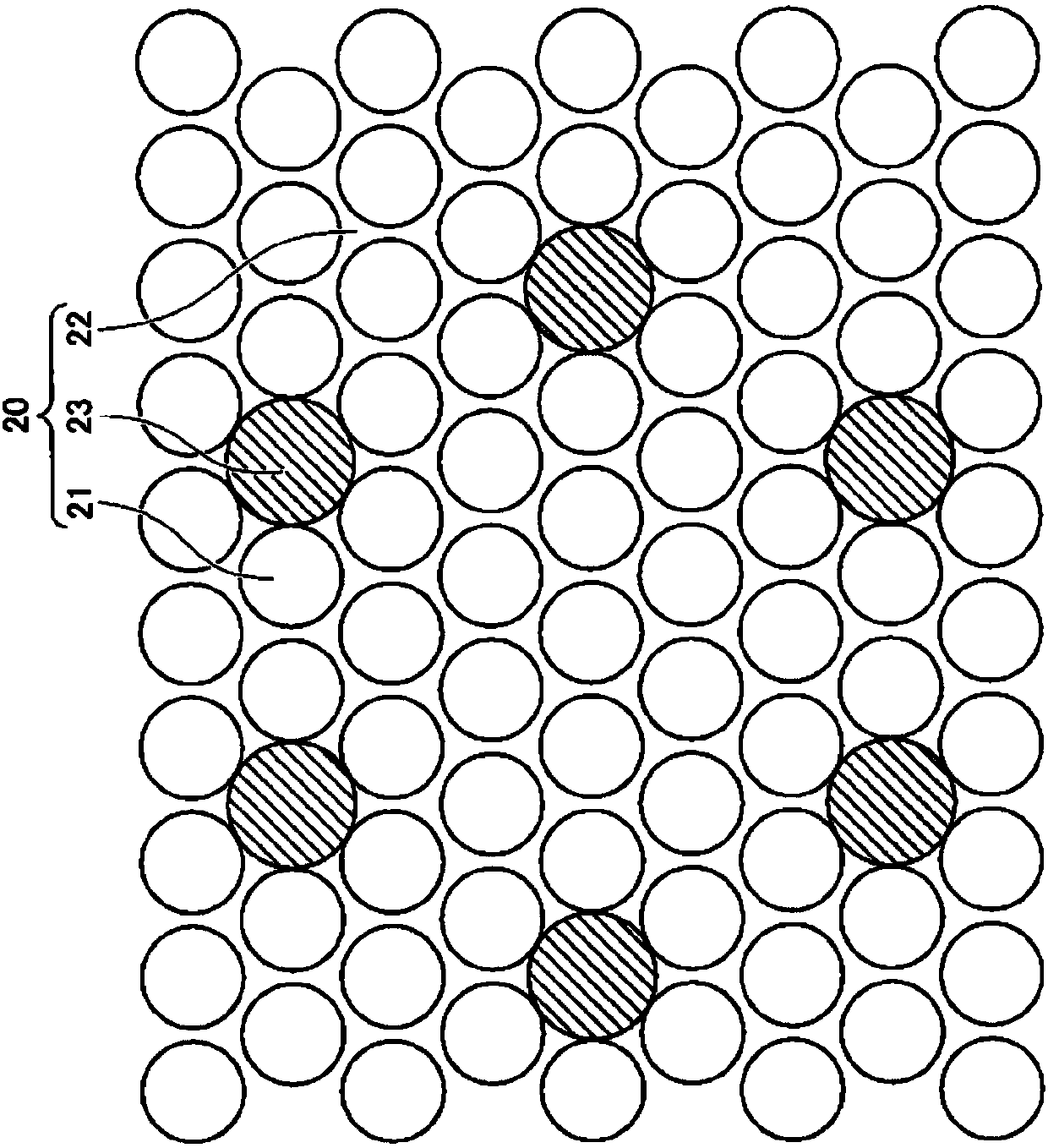

[0460] The mask pattern formed is and Figure 25 In the same convex pattern, the convex portions are arranged in a hexagonal grid with a lattice constant of 0.70 μm pitch, and the flat portions without the convex pattern are located at each vertex of a regular hexagon with one side of 1.40 μm and are repeatedly arranged.

[0461] Diameter of convex mask: 0.62μm

[0462] Height of convex mask: 1.47μm

[0463] Protruding mask pitch (Pn): 0.70μm

[0464] Plane pitch between convex masks (Pe): 1.40μm

[0465] Then, through the ICP dry etching device, using the mask pattern as a mask, through BCl 3 Gas and Cl 2 The gas mixture performs reactive ion etching to et...

Embodiment 5

[0477] The sapphire substrate produced in Example 4 was set in a MOCVD device to produce an LED. First, heat in a hydrogen atmosphere, after the surface is cleaned, and then form a film Al x Ga 1-x N(0≦x≦1) low temperature growth buffer layer. Next, a non-doped GaN layer is formed, and the composition ratio of the raw materials, the film formation temperature, and the film formation pressure are appropriately adjusted to fill the unevenness on the surface of the sapphire substrate with the GaN layer to obtain a flat undoped GaN layer.

[0478] The half-value width of the X-ray rocking curve (XRC-FWHM) of GaN (102) was measured, and the crystal quality of the undoped GaN layer was evaluated.

[0479] (XRC)

[0480] Device: X-Ray diffractometer (X-ray diffractometer)_SmartLab (manufactured by Rigaku)

[0481] Tube voltage: 45keV

[0482] Tube current: 200mA

[0483] Next, as the n-type GaN layer, Si-doped GaN is formed. Next, the strain absorbing layer is provided. Then, as a light-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com