Preparation method of high-purity metallic rubidium and cesium

A technology of metal rubidium and metal cesium, applied in the field of metal rubidium and cesium preparation, can solve the problems of poor separation and recovery, complicated extraction process, high cost, etc., and achieve the effect of increasing the value of by-products, simple process, and easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

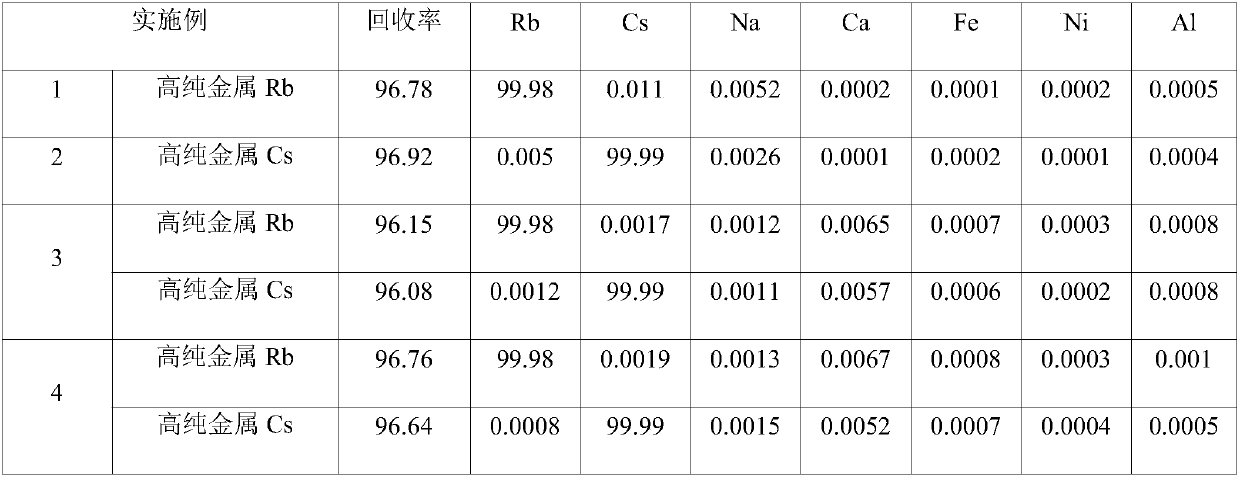

[0041] A preparation method of high-purity metal rubidium, comprising the following steps:

[0042] (1) Place the sample A01 in a vacuum reactor, and dehydrate it through low-temperature preheating treatment. The dehydration temperature is controlled at 200°C for 120 minutes to obtain the pretreated compound;

[0043] (2) Material mixing: mix the pretreatment compound A01 with the reducing agent metal magnesium, calcium, and lithium according to the stoichiometric ratio of 0.75:0.95:0.04:0.01, and then mix evenly in a vacuum glove box with an argon atmosphere, press the cake and load the sample ;

[0044] (3) High-temperature reduction: Place the loading sample obtained in step (2) in a stainless copper reactor, then seal the reactor, evacuate to -0.025-0.03MPa, and then feed inert gas into the reactor. 0.45-0.50MPa, repeat this operation three times to ensure that the gas atmosphere is inert, then raise the temperature to 600°C at 5°C / min, keep the temperature for 30 minutes a...

Embodiment 2

[0048] A preparation method of high-purity metallic cesium, comprising the following steps:

[0049] (1) Place the sample A02 in a vacuum reactor and dehydrate it through low-temperature preheating treatment. The dehydration temperature is controlled at 200°C for 120 minutes to obtain the pretreated compound;

[0050] (2) Material mixing: mix the pretreatment compound A02 with the reducing agent metal magnesium, calcium, and lithium according to the stoichiometric ratio of 1.35:0.90:0.06:0.04, and then mix evenly in a vacuum glove box with an argon atmosphere, press the cake and load the sample ;

[0051] (3) High-temperature reduction: Place the loading sample obtained in step (2) in a stainless copper reactor, then seal the reactor, evacuate to -0.02-0.025MPa, and then feed inert gas into the reactor. 0.45-0.50MPa, repeat this operation three times to ensure that the gas atmosphere is inert, then raise the temperature to 300°C at 5°C / min, keep the temperature for 30 minutes...

Embodiment 3

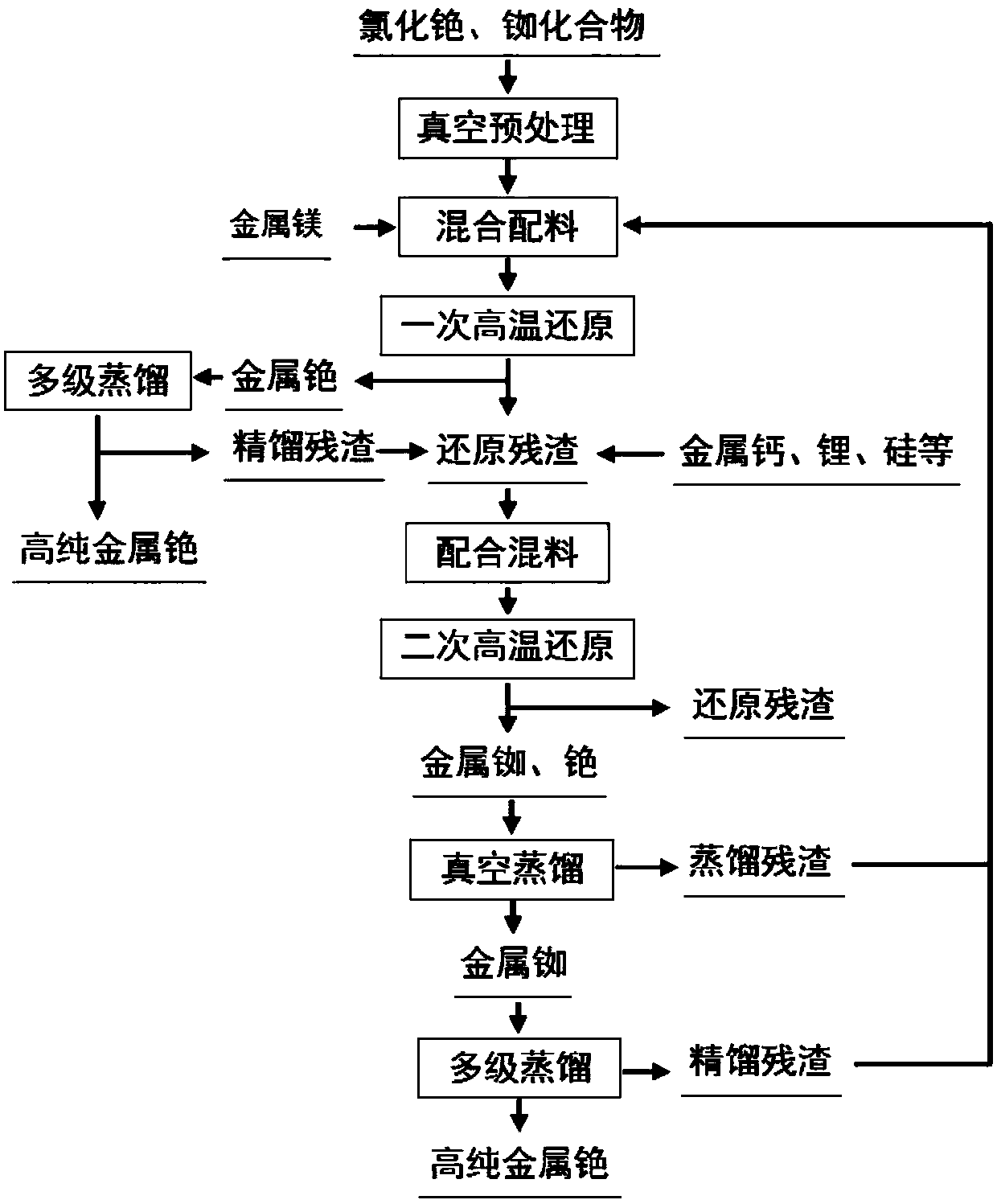

[0055] Such as figure 1 Shown, a kind of preparation method of high-purity metallic rubidium and cesium comprises the following steps:

[0056] (1) Place the sample A03 in a vacuum reactor and dehydrate it through low-temperature preheating treatment. The dehydration temperature is controlled at 200°C for 120 minutes to obtain the pretreated compound;

[0057] (2) Material mixing: the pretreatment compound A03 and the primary reducing agent metal magnesium are proportioned according to the stoichiometric ratio of 1.55:1, and then mixed evenly in a vacuum glove box with argon atmosphere, cake pressing and sample loading;

[0058] (3) One-time high-temperature reduction: put the loaded sample obtained in step (2) in a stainless copper reactor, then seal the reactor, vacuumize to -0.025 ~ 0.03MPa, and then pass inert gas into the reactor 0.35~0.45MPa, repeat this operation three times to ensure that the gas atmosphere is inert, then raise the temperature to 300°C at 5°C / min, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com