Bacterial strain for co-producing chitosanase and gamma-polyglutamic acid and application thereof

A technology for producing chitosanase and polyglutamic acid, applied in the direction of glycosylase, enzymes, bacteria, etc., can solve the problems that have not been reported on the co-production of chitosanase and polyglutamic acid strains, and achieve Effects of high γ-polyglutamic acid production capacity, simple medium composition, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

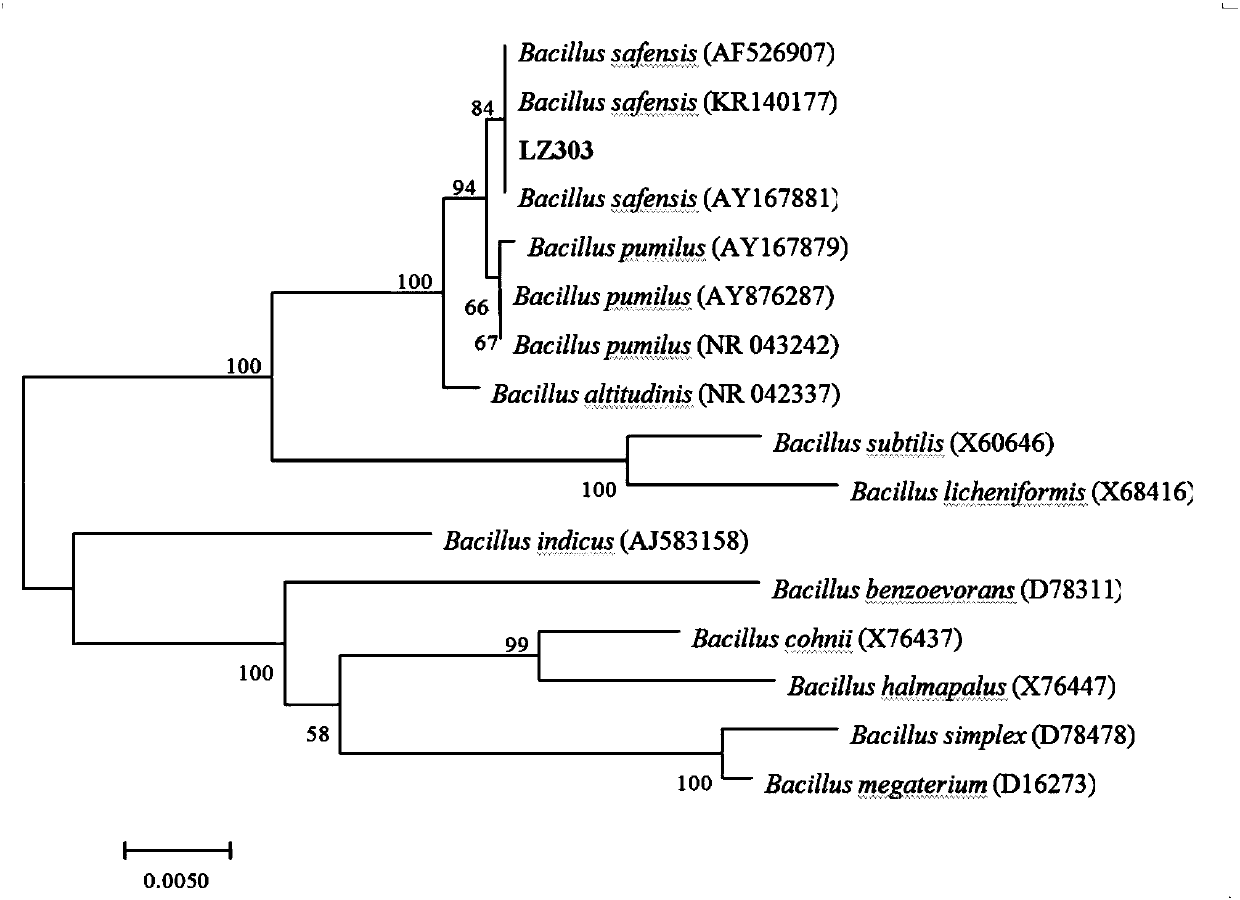

[0033] Example 1: Classification of Bacillus suffolus strains

[0034] 1) Characteristics of strains

[0035] On the preservation medium, the colonies are off-white, nearly round, with smooth, moist and raised surfaces, and irregular edges; observed by an optical microscope, the bacteria are straight rod-shaped, not chained, with blunt round ends, spores, and Gram-positive. Strain LZ303 can decompose sucrose, glucose and sorbose, but cannot decompose starch. The results of methyl red test, V-P test, oxidase, catalase, catalase and urease test were positive, and the test results of nitrate reduction, indole production and gelatin liquefaction were negative. It grew well in 10% NaCl medium, and the test results are shown in Table 1. Based on the above test results, the strain LZ303 was preliminarily identified as Bacillus sp. according to the "Common Bacteria System Identification Manual". The comparison results of specific physiological and biochemical characteristics are sh...

Embodiment 2

[0049] Embodiment 2 strain culture and chitosanase fermentation

[0050] 1) Strain activation: pick the strains and inoculate them on a solid slant medium: 2g / L sucrose, 5g / L yeast extract powder, 5g / L peptone, 5g / L tryptone, 5g / L NaCl, 18g / L agar , pH 7.0, sterilized by high-pressure steam at 121°C for 20 minutes; streak inoculated in a constant temperature incubator at 30°C for 20 hours;

[0051] 2) Preparation of liquid seeds: Pick one ring of activated strains and inoculate them in a 500mL Erlenmeyer flask containing 50mL of seed medium. The components of liquid seed medium: 3g / L sucrose, 5g / L yeast extract powder, 5g / L peptone, Tryptone 3g / L, KH 2 PO 4 1g / L, NaCl 2.5g / L, pH 7.0, sterilized by high-pressure steam at 115°C for 20min; seal with eight layers of gauze, shake and culture at 30°C, 200r / min shaker for 18h to obtain liquid seeds;

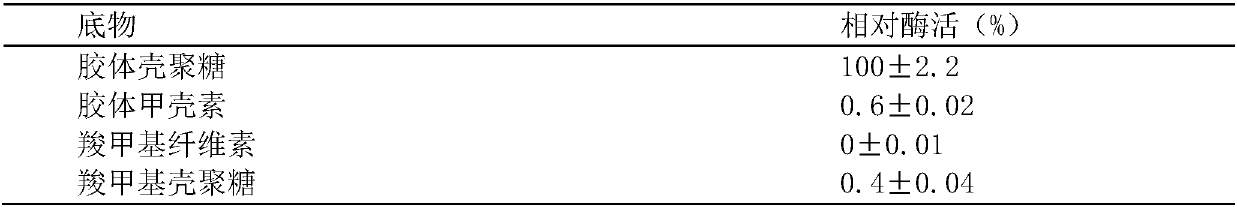

[0052] 3) liquid fermentation: according to 5% inoculation amount, the components are glucose 10g / L, colloidal chitosan 5g / L, pept...

Embodiment 3

[0053] Example 3 strain culture and gamma-polyglutamic acid fermentation

[0054] 1) Strain activation: pick the strains and inoculate them on a solid slant medium: 2g / L sucrose, 5g / L yeast extract powder, 5g / L peptone, 5g / L tryptone, 5g / L NaCl, 18g / L agar , pH 7.0, sterilized by high-pressure steam at 121°C for 20 minutes; streak inoculated in a constant temperature incubator at 30°C for 18 hours;

[0055] 2) Preparation of liquid seeds: Pick one ring of activated strains and inoculate them in a 500mL Erlenmeyer flask containing 50mL of seed medium. The components of liquid seed medium: 3g / L sucrose, 5g / L yeast extract powder, 5g / L peptone, Tryptone 5g / L, KH 2 PO 4 1g / L, NaCl 2g / L, pH 7.0, sterilized by high-pressure steam at 115°C for 20min; seal with eight layers of gauze, and shake at 30°C and 200r / min for 18h to obtain liquid seeds;

[0056] 3) liquid fermentation: according to 10% inoculum size, the composition is 30g / L of sucrose, 5g / L of glycerol, 30g / L of L-glutamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com