Polyacrylonitrile nano fiber film and thermoplastic polyurethane composite material and preparation method thereof

A thermoplastic polyurethane, nanofiber membrane technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of tension, tensile strength elongation, toughness and other problems, achieve low equipment requirements, easy availability of raw materials, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a thermoplastic polyurethane material, specifically comprising the following steps:

[0035] (1) Preparation of polyacrylonitrile solution: Add 1.2000 grams of polyacrylonitrile with a molecular weight of 50,000 to 13.8000 grams of solvent N,N dimethylformamide at a temperature of 20°C, and mix and stir for 4 hours to obtain the mass percentage of polyacrylonitrile 8% polyacrylonitrile solution;

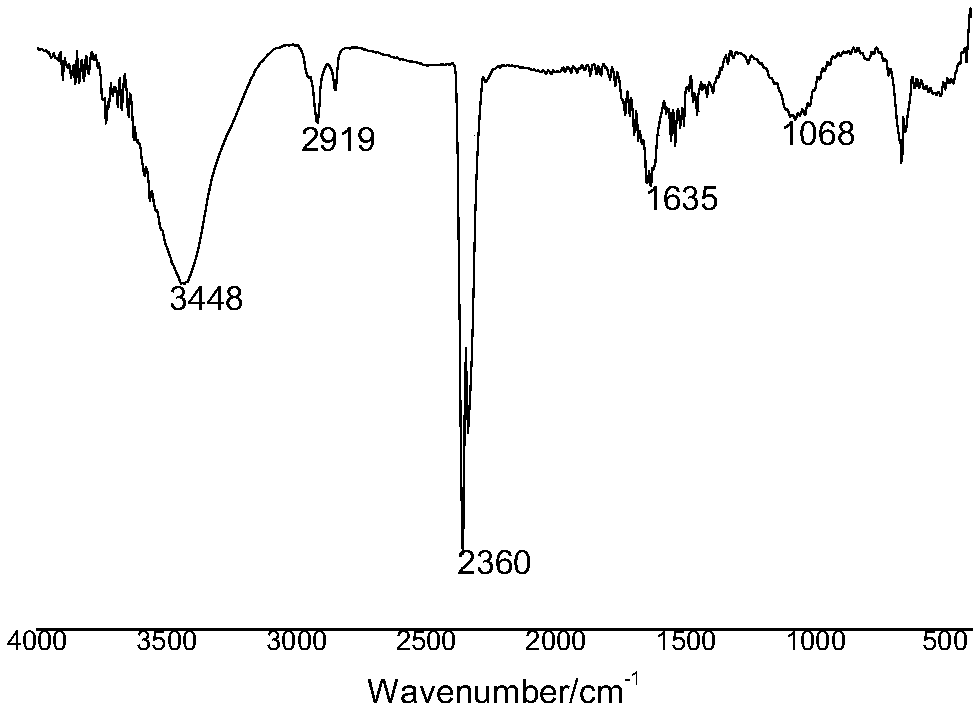

[0036] (2) Preparation of polyacrylonitrile nanofiber membrane: the polyacrylonitrile solution obtained in step (1) is prepared by electrospinning to obtain polyacrylonitrile nanofiber membrane; the electrospinning parameters are: voltage 8KV, spinning distance 8cm , the drum speed is 10rpm, the nozzle speed is 0.20ml / h; the diameter of the fiber prepared by electrospinning is 100nm-300nm.

[0037] (3) Preparation of thermoplastic polyurethane mixed solution: at a temperature of 240°C, dissolve thermoplastic polyurethane in an organic solvent (one or m...

Embodiment 2

[0041] A preparation method of polyacrylonitrile nanofiber film / thermoplastic polyurethane composite material, specifically comprising the following steps:

[0042] (1) Preparation of polyacrylonitrile solution: Add 1.1954g polyacrylonitrile with a molecular weight of 85000 to 8.0000g solvent N,N dimethylformamide at a temperature of 28°C, mix for 6 hours and stir to obtain the mass of polyacrylonitrile 13% polyacrylonitrile solution;

[0043] (2) Preparation of polyacrylonitrile nanofiber membrane: the polyacrylonitrile solution obtained in step (1) is prepared by electrospinning to obtain polyacrylonitrile nanofiber membrane; the electrospinning parameters are: voltage 25KV, spinning distance 12cm , the drum speed is 0, the nozzle speed is 0.65ml / h, and the diameter of the fiber prepared by electrospinning is 300nm-500nm.

[0044] (3) Preparation of thermoplastic polyurethane mixed solution: at a temperature of 240°C, dissolve thermoplastic polyurethane in an organic solvent ...

Embodiment 3

[0048] A preparation method of polyacrylonitrile nanofiber film / thermoplastic polyurethane composite material, specifically comprising the following steps:

[0049] (1) Preparation of polyacrylonitrile solution: Add 0.5973g polyacrylonitrile with a molecular weight of 130000 to 3.2827g solvent N,N dimethylformamide at a temperature of 30°C, mix for 12 hours and stir to obtain the mass of polyacrylonitrile 15% polyacrylonitrile solution;

[0050] (2) Preparation of polyacrylonitrile nanofiber membrane: the polyacrylonitrile solution obtained in step (1) is prepared by electrospinning to obtain polyacrylonitrile nanofiber membrane; the electrospinning parameters are: voltage 26KV, spinning distance 11cm , the drum speed is 440, the nozzle speed is 0.66ml / h, and the experiment is carried out for 3h; the diameter of the fiber prepared by electrospinning is 200nm~1.2um.

[0051] (3) Preparation of thermoplastic polyurethane mixed solution: at a temperature of 230°C, dissolve therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com