A kind of upsetting extrusion forming method of bimetal material drug-type cover

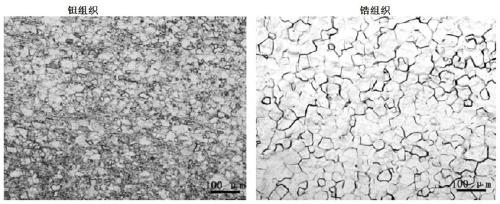

A medicine-shaped hood, bimetal technology, applied in metal processing equipment, furnace type, furnace and other directions, can solve the problems of uneven grain size, complex finishing process, difficult processing, etc., to achieve good dimensional specification consistency, improve The material utilization rate and the effect of small external interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

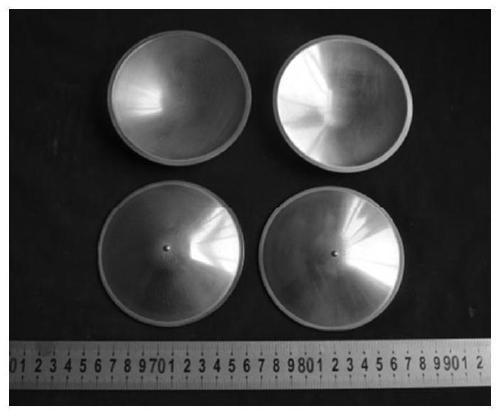

Examples

Embodiment 1

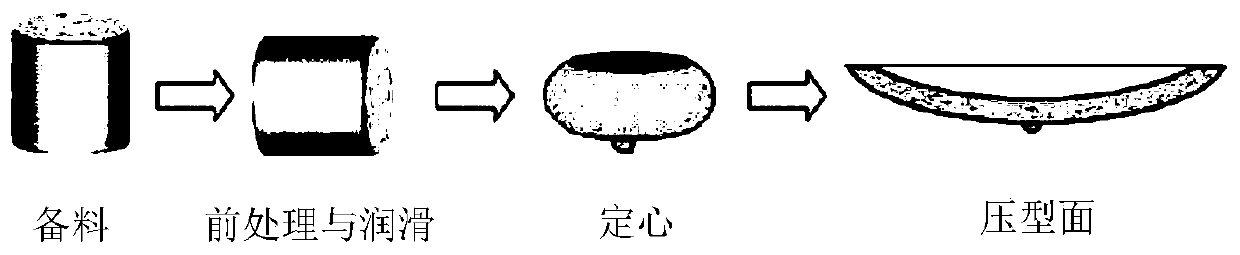

[0035] A preparation method of a bimetallic drug-type cover, carried out according to the following steps:

[0036] (1) Preparation of the blank: Take the variable-wall-thick drug-type cover with the shape of the spherical segment as an example. The diameter of the drug-type cover is 100mm, the radius of the outer spherical surface is 110mm, the radius of the inner spherical surface is 132mm, and the cone angle is 27°; according to the theory of plastic processing Based on the principle of near-uniform plastic deformation, a 3mm machining allowance is left on one side of the flange of the drug-type cover, and a φ4mm positioning bump is designed at the bottom of the spherical center of the drug-type cover; the forming process is simulated and analyzed by UG and DEFORM software and optimization, and calculate the volume of the blank, select a tantalum-zirconium bimetallic material with a thickness of 4mm (the thickness ratio of tantalum-zirconium is 3:1).

[0037](2) Homogenizat...

Embodiment 2

[0046] A preparation method of a bimetallic drug-type cover, carried out according to the following steps:

[0047] (1) Preparation of blanks: Take the eccentric sub-hemispherical structure of variable-wall-thick drug-mold as an example. The diameter of the drug-mask is 139mm, the radius of the outer spherical surface is 140mm, the radius of the inner spherical surface is 145mm, and the cone angle is 33°; it is formed according to plastic processing Based on the theory and the principle of near-uniform plastic deformation, a 4mm machining allowance is left on one side of the flange of the drug-type cover, and a φ4mm positioning bump is designed at the bottom of the spherical center of the drug-type cover; UG and DEFORM software are used to simulate the forming process Analyze and optimize, and calculate the volume of the blank, select a 6mm thick tantalum-zirconium bimetallic material (the thickness ratio of tantalum-zirconium is 2:1).

[0048] (2) Homogenization heat treatmen...

Embodiment 3

[0058] A preparation method of a bimetallic drug-type cover, carried out according to the following steps:

[0059] (1) Preparation of blanks: Take the variable-wall-thick drug-type cover with spherical crown structure as an example. The diameter of the drug-type cover is 132mm, the radius of the outer spherical surface is 118mm, and the radius of the inner spherical surface is 136mm; based on the theory of plastic processing and nearly uniform plastic deformation The principle is to leave a 3.5mm machining allowance on one side of the flange of the caliber of the drug cover, and design a φ4mm positioning bump at the bottom of the spherical center of the drug cover; use UG and DEFORM software to simulate, analyze and optimize the forming process, and Calculate the volume of the blank, and select a tantalum-zirconium bimetallic material with a thickness of 5mm (the thickness ratio of tantalum-zirconium is 3:2).

[0060] (2) Homogenization heat treatment: heat the blank obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com