In situ preparation method of a multilayer core-shell nanostructure and its application in the preparation of electromagnetic wave absorbing materials

A nanostructure and in-situ preparation technology, applied in magnetic materials, nanotechnology, nanotechnology, etc., can solve the problems of flammable and explosive reactions, poor quality of nanostructures, toxic and harmful tail gas, etc., and achieve controllable reaction conditions and improved Effect of return loss and size controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

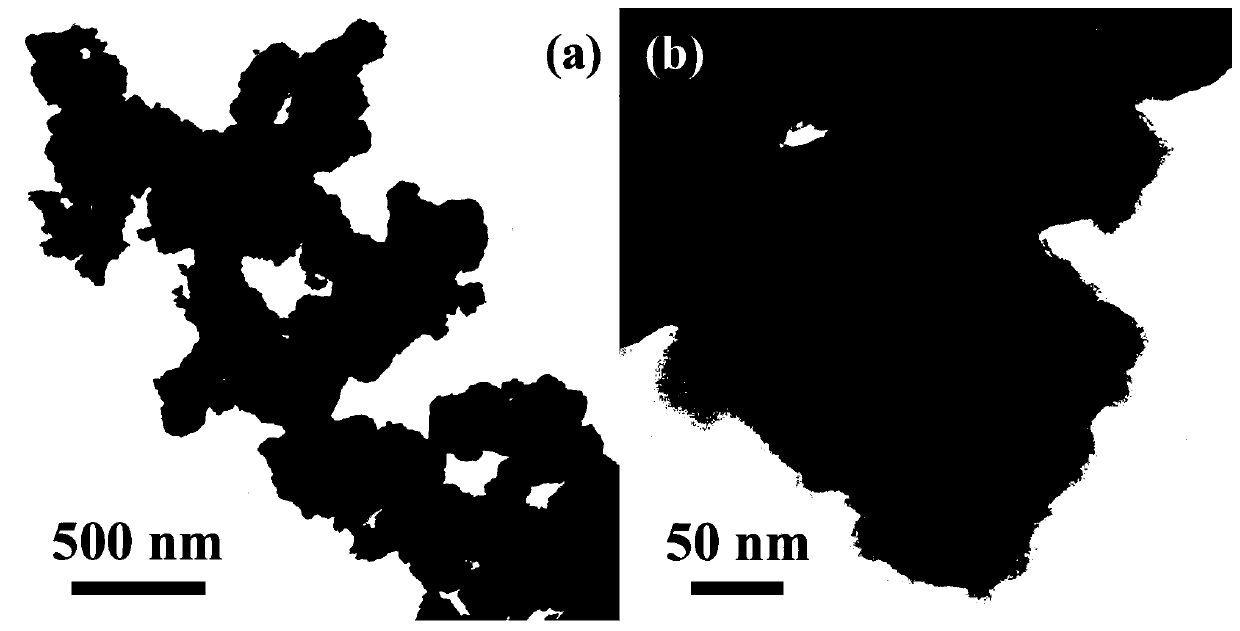

[0047] The in-situ preparation method of the ferrite / oxide / polymer multilayer core-shell nanostructure in this example is as follows:

[0048] 1. Fe 3 o 4 Preparation of magnetic cores

[0049] 1a. Add 2mmol of ferric chloride (FeCl 3 ), and stir evenly, and prepare ferric chloride alcohol solution; add 0.2g polyethylene glycol (PEG) to the obtained ferric chloride alcohol solution, and the device is fed with nitrogen protection, and with a heating rate of 5° C. / min, from The room temperature began to warm up to 220°C, and the reaction was refluxed and stirred at 220°C at a rate of 500rpm for 1h;

[0050] 1b. Dissolve 1g of sodium hydroxide (NaOH) in 20ml of diethylene glycol to prepare an alcoholic sodium hydroxide solution, and quickly inject 1.75ml of the alcoholic sodium hydroxide solution through a needle into the reaction solution obtained in 1a at 220°C In the process, a black precipitate was produced immediately, and the stirring was continued for 1 h at 220 ° C in...

Embodiment 2

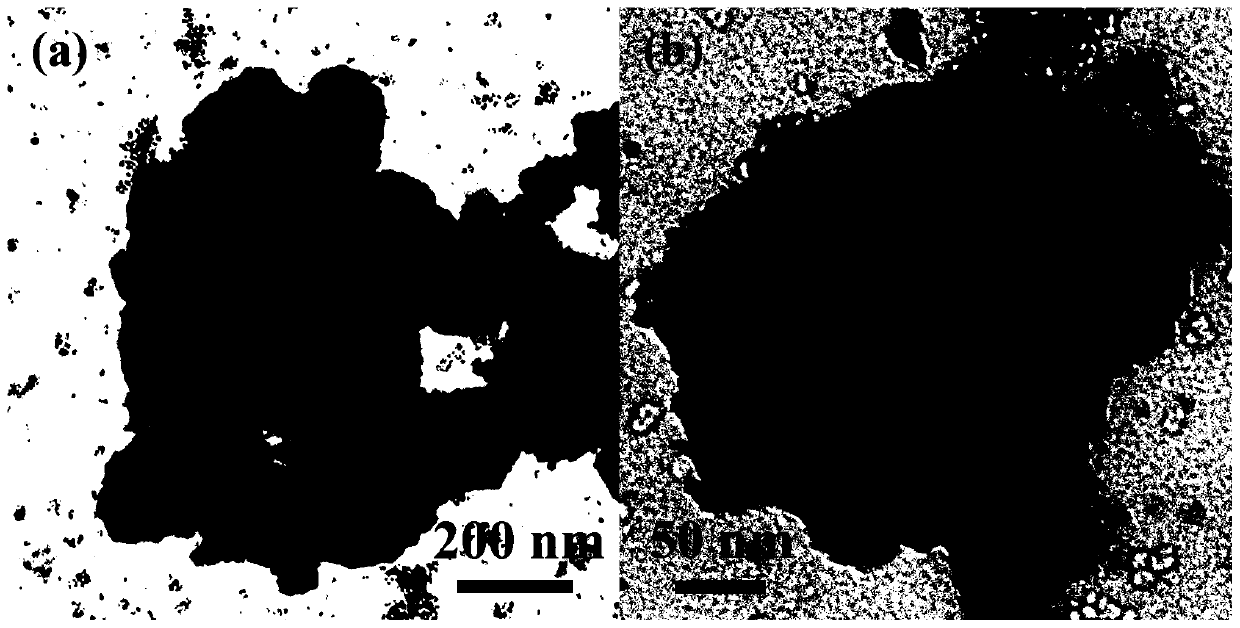

[0058] The in-situ preparation method of the ferrite / oxide / amorphous oxide multilayer core-shell nanostructure in this example is as follows:

[0059] 1. Fe 3 o 4 Preparation of magnetic cores

[0060] 1a. Add 2mmol of ferric chloride (FeCl 3 ), and stir evenly, and prepare ferric chloride alcohol solution; add 0.2g polyethylene glycol (PEG) to the obtained ferric chloride alcohol solution, and the device is fed with nitrogen protection, and with a heating rate of 5° C. / min, from The room temperature began to warm up to 220°C, and the reaction was refluxed and stirred at 220°C at a rate of 500rpm for 1h;

[0061] 1b. Dissolve 1g of sodium hydroxide (NaOH) in 20ml of diethylene glycol to prepare an alcoholic sodium hydroxide solution, and quickly inject 1.75ml of the alcoholic sodium hydroxide solution through a needle into the reaction solution obtained in 1a at 220°C In the process, a black precipitate was produced immediately, and the stirring was continued for 1 h at 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com