Method for controlling damping factor of MRAM (Magnetic Random Access Memory) material

A damping factor and system technology, applied in the field of magnetic material growth and time-resolved detection of femtosecond lasers, can solve the problems of complex MRAM device structure and fabrication process, unfavorable for integrated device fabrication, etc., and achieve low power consumption, high thermal stability, The effect of high-speed MRAM read and write

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

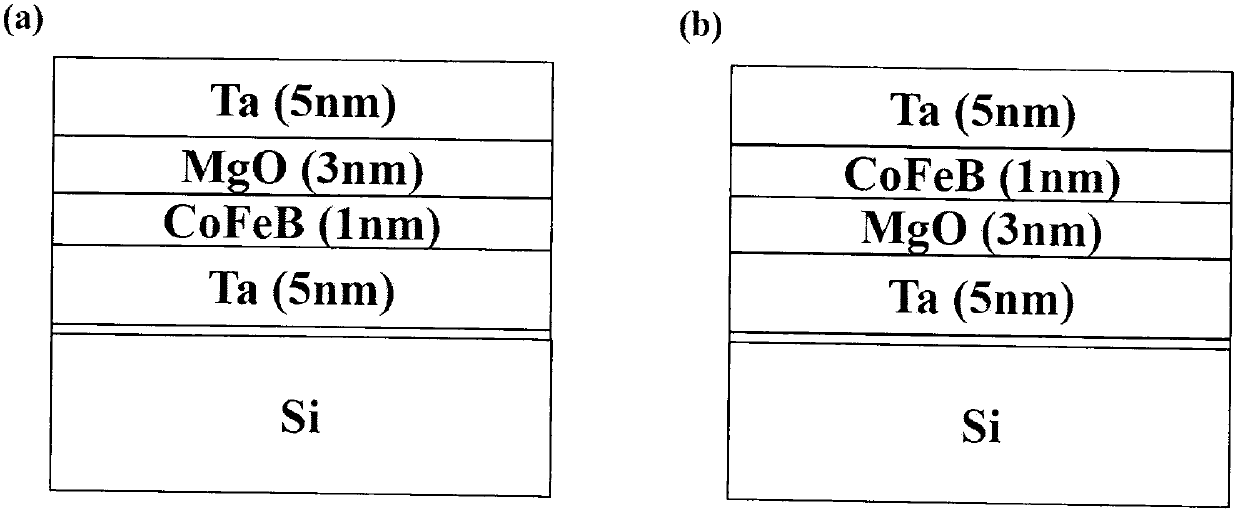

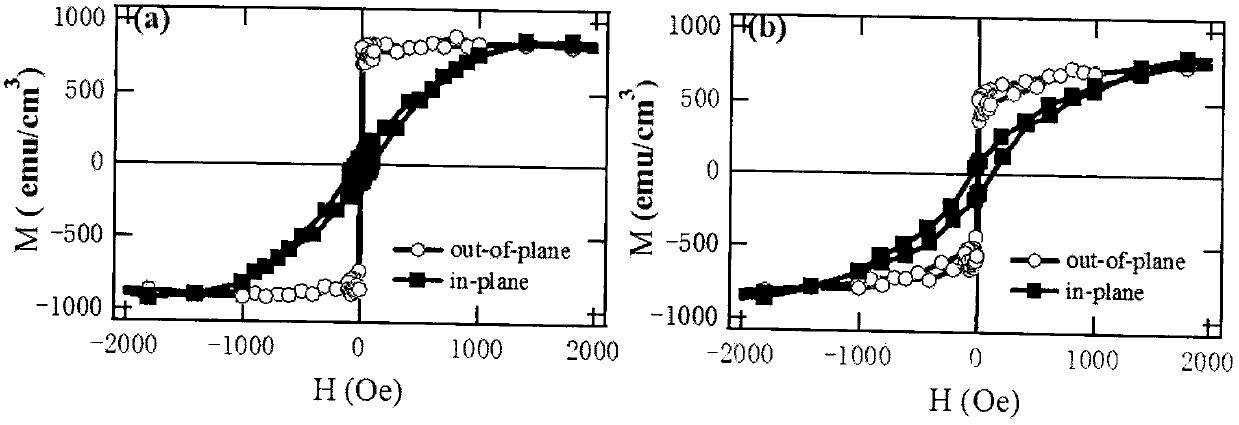

[0022] In order to achieve the above object, the present invention first prepared the material structure substrate / Ta(5) / CoFeB(1) / MgO(3) / Ta(5) and substrate / Ta(5) / MgO(3) / CoFeB(1) / Ta(5) (the number represents the thickness of the film, the unit is nanometers), such as figure 1 shown. The magnetic film structure has perpendicular magnetic anisotropy, coercive force H C 5.31Oe and 5.66Oe respectively, the saturation magnetization field M S 890emu / cm 3 、836emu / cm 3 ,like figure 2 shown.

[0023] The samples involved in the present invention are grown by magnetron sputtering. First, the surface of the Si substrate is cleaned by blowing the surface of the substrate with a nitrogen stream. The vacuum was maintained at 10 when the sample was sputtered -6 Pa or so.

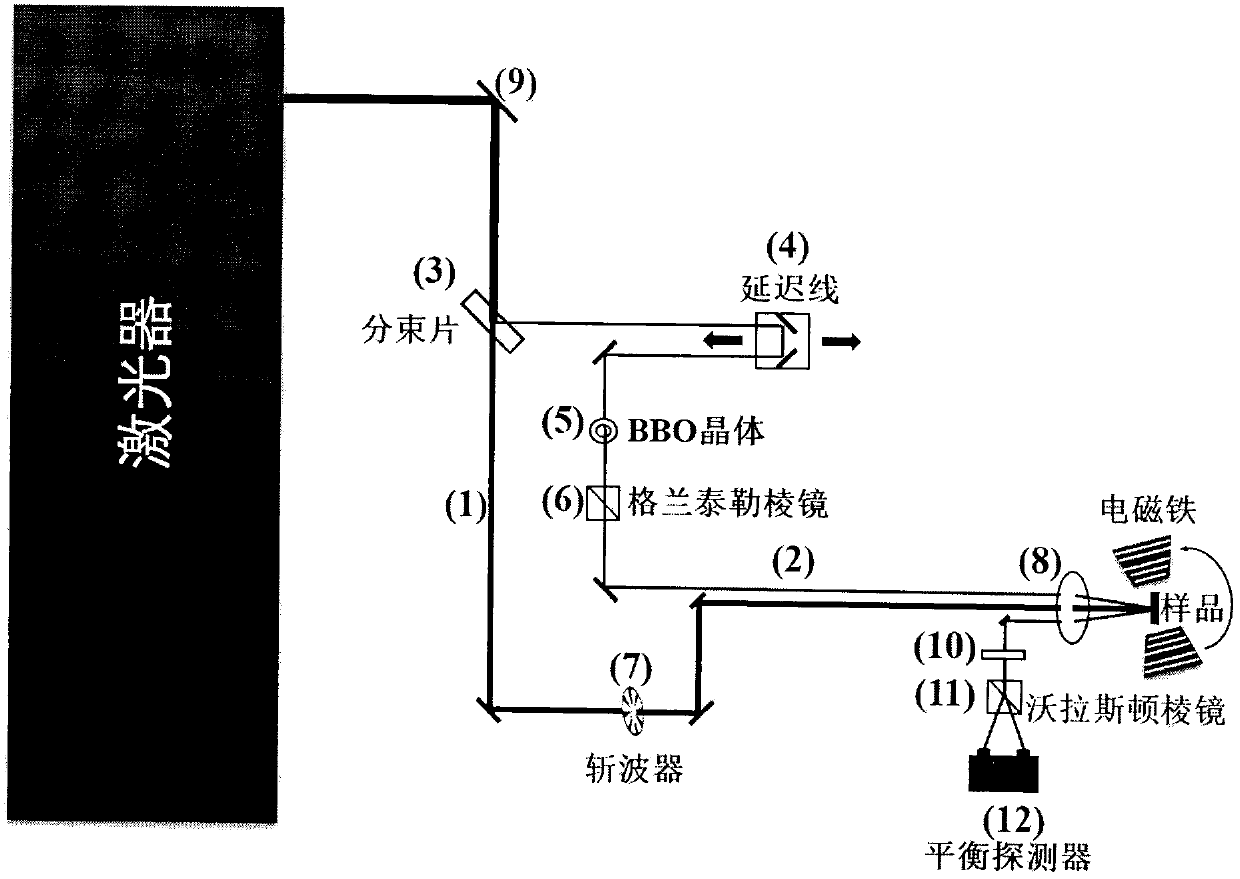

[0024] In order to complete the above invention, the experimental scheme we adopt is to use the time-resolved magneto-optical Kerr effect means, using such image 3 The experimental system shown.

[0025] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com