Equipment and method for removing iron and organic matters from neodymium-iron-boron oil sludge waste material through air and ozone two-stage oxidization by wet method at normal temperature

A neodymium iron boron and oil sludge technology, applied in the chemical industry, can solve the problems of waste gas emission and environmental treatment cost increase, and achieve the effects of reducing emissions, improving removal efficiency, and high environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

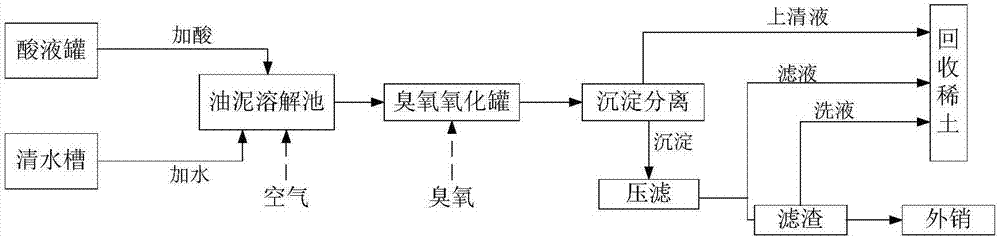

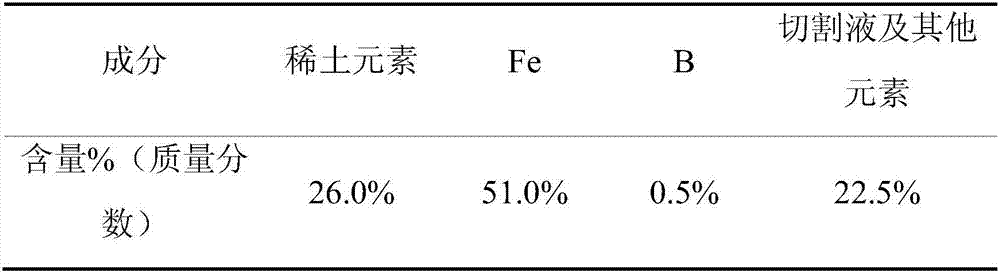

[0022] The raw material to be processed in the invention is the sludge waste produced during the grinding and wire cutting of sintered NdFeB magnets, which is the waste formed by mixing NdFeB powder and cutting fluid. The components of NdFeB sludge are shown in Table 1, and the components of rare earth in NdFeB sludge are shown in Table 2. The main organic components of the cutting fluid include: organic amines, organic acids, phosphates, polyethers, organic rust inhibitors, organic surfactants, etc.

[0023] Table 1 Composition of NdFeB sludge waste

[0024]

[0025] Table 2 Composition of rare earths in NdFeB oil sludge

[0026]

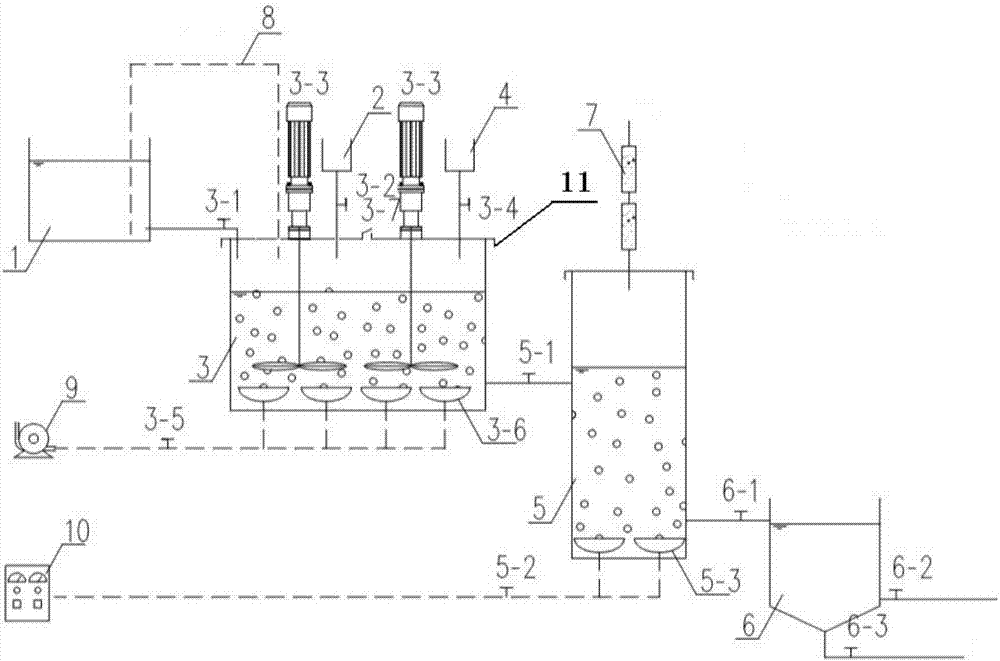

[0027]The equipment of the present invention is mainly composed of clear water tank (1), dissolution tank (3), ozone oxidation tank (5), sedimentation tank (6), air pump (9) and ozone generator (10). The clear water tank (1) is high I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com