Auricularia auricula-judae wall-breaking method

A technology of black fungus and bacillus, applied in the field of black fungus wall breaking, can solve the problems of low absorption and utilization rate, and achieve the effects of low cost, less equipment investment and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

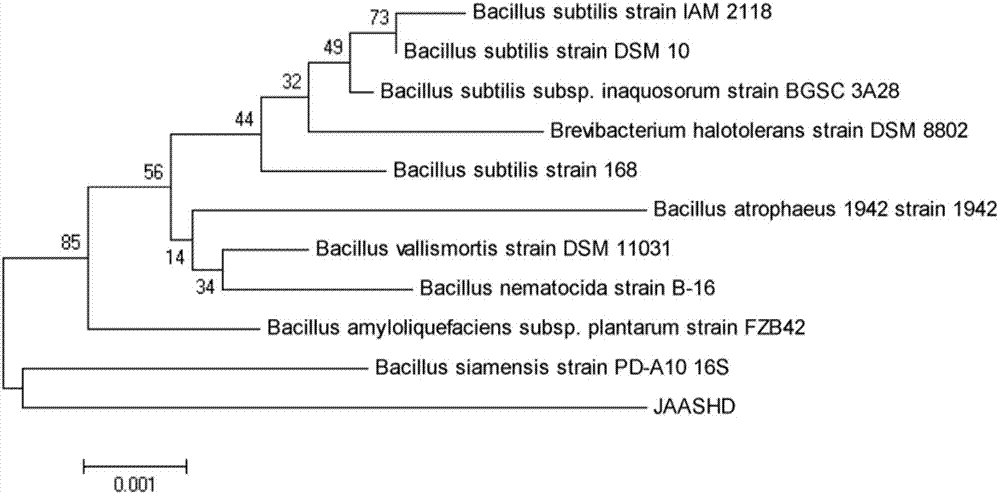

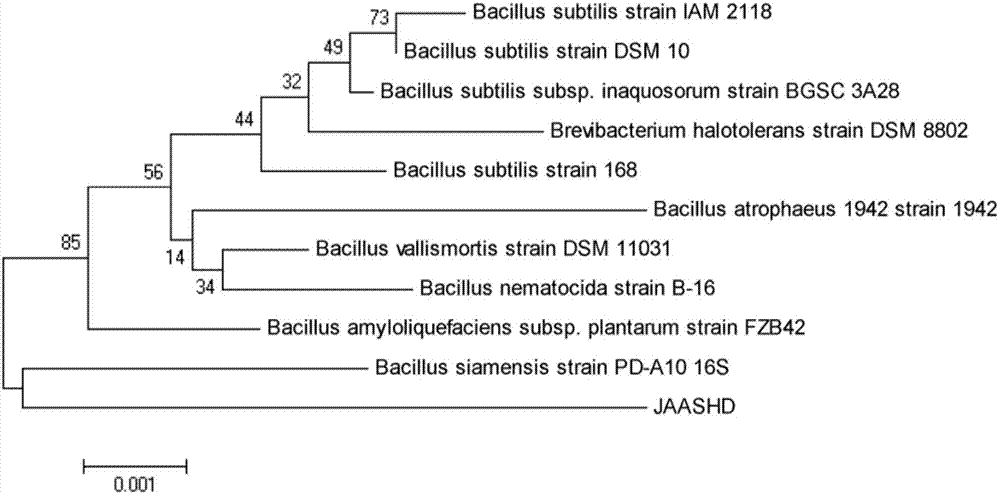

[0032] 1. Primary screening of strains

[0033] Collect 10 fresh feces samples of healthy piglets from all over Jilin Province, weigh 10g samples respectively, add 90mL sterile saline to prepare a sample suspension, and take 100μL 10 -2 、10 -3 、10 -4 The diluted solution was spread on the LB medium plate, and each gradient was spread in three parallels, and cultured at a constant temperature of 37°C for 48 hours, and then the bacillus strains were purified by plate streaking method, and were numbered and stored separately. 122 strains of Bacillus were obtained.

[0034] 2. Preliminary screening of chitinase-producing bacillus

[0035] Spot the isolated strains on the above-mentioned separation plate with chitin powder as the only carbon source, and incubate at 37°C for 16-48 hours. If a transparent hydrolysis circle appears around the grown colony, it means that the chitin in the medium has been It is hydrolyzed by the enzyme secreted by the strain, which proves that the s...

Embodiment 2

[0055] The preparation of embodiment 2 bacillus siamese JAASHD broken wall black fungus powder

[0056] Preparation of crude enzyme solution:

[0057] Inoculate the strain JAASHD in LB liquid fermentation medium, place on a shaker at 35°C, 240rpm, shake to OD 600 The value 0.8 is taken out. Centrifuge at 6000rpm for 20min, discard the precipitate, and filter the supernatant at 0.22um to obtain the crude enzyme solution.

[0058] The composition of the LB liquid fermentation medium is: peptone 12g / L, yeast powder 2g / L, sodium chloride 4g / L, glucose 2g / L, deionized water 1000mL; pH=6.2. Autoclaved at 121°C for 20min.

[0059] Breaking the wall of black fungus fruiting bodies:

[0060] The black fungus powder is added into the crude enzyme liquid at 10% (w / v), shaken gently, statically hydrolyzed at 36° C. to 38° C. for 24 hours, and then dried to obtain the broken black fungus powder.

Embodiment 3

[0061] The preparation of embodiment 3 bacillus siamese JAASHD broken wall black fungus powder

[0062] Preparation of crude enzyme solution:

[0063] Inoculate the strain JAASHD in LB liquid fermentation medium, place on a shaker at 42°C, 150rpm, shake to OD 600 A value of 1.0 is taken out. Centrifuge at 10,000rpm for 15min, discard the precipitate, and filter the supernatant at 0.22um to obtain the crude enzyme solution.

[0064] The composition of the LB liquid fermentation medium is: peptone 8g / L, yeast powder 4g / L, sodium chloride 6g / L, glucose 4g / L, deionized water 1000mL; pH=7.0. Autoclaved at 121°C for 20min.

[0065] Breaking the wall of black fungus fruiting bodies:

[0066] The black fungus powder is added into the crude enzyme solution at a rate of 30% (w / v), shaken gently, statically hydrolyzed at 36° C. to 38° C. for 48 hours, and then dried to obtain the broken black fungus powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com