Sludge freezing dehydration device and sludge dehydration method

A freeze dehydration and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption, poor stability, and low safety of sludge dehydration, and achieve Low odor volatilization rate, good effect and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

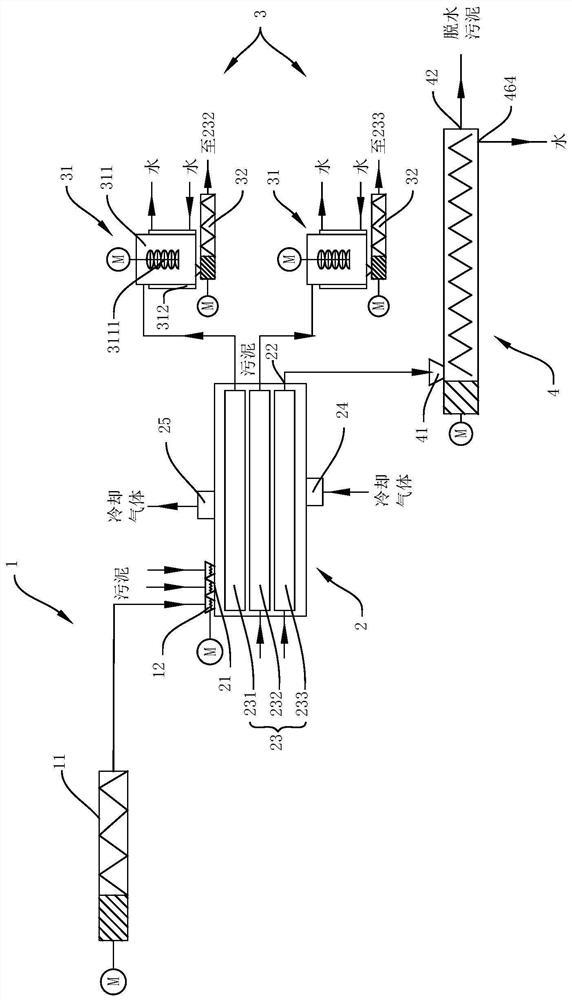

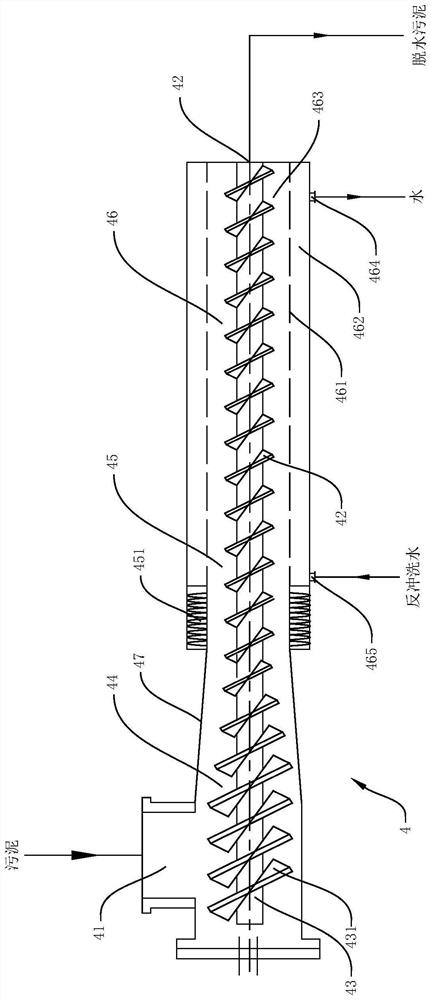

[0029] see figure 1 A kind of sludge freezing dehydration device shown, comprises feeding device 1, freezing treatment device and screw extrusion filter 4, wherein, feeding device 1 specifically comprises screw pump 11 and the granulator 12 that is connected at its rear end, The freezing treatment device includes a freezer 2 and a crushing device 3, and the crushing device 3 includes a crusher 31 and a sludge conveyor 32 connected to the rear end thereof.

[0030] The freezer 2 has a freeze feed inlet 21 connected to the granulator 12 and a freeze discharge outlet 22 connected to the screw extrusion filter 4. In the present embodiment, the freezer 2 is provided with three freeze transfer belts 23, along the dirt Mud transmission direction is successively the first conveyor belt 231, the second conveyor belt 232 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com