Core-shell structure particles of electro-conductive macromolecule coated polymer microspheres and preparation method thereof

A technology of conductive polymer and core-shell structure, which is applied in the field of nanoparticle synthesis, can solve the problems of environmental pollution and increase the cost of core-shell structure particle synthesis, and achieve the effects of low cost, reduced synthesis cost, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

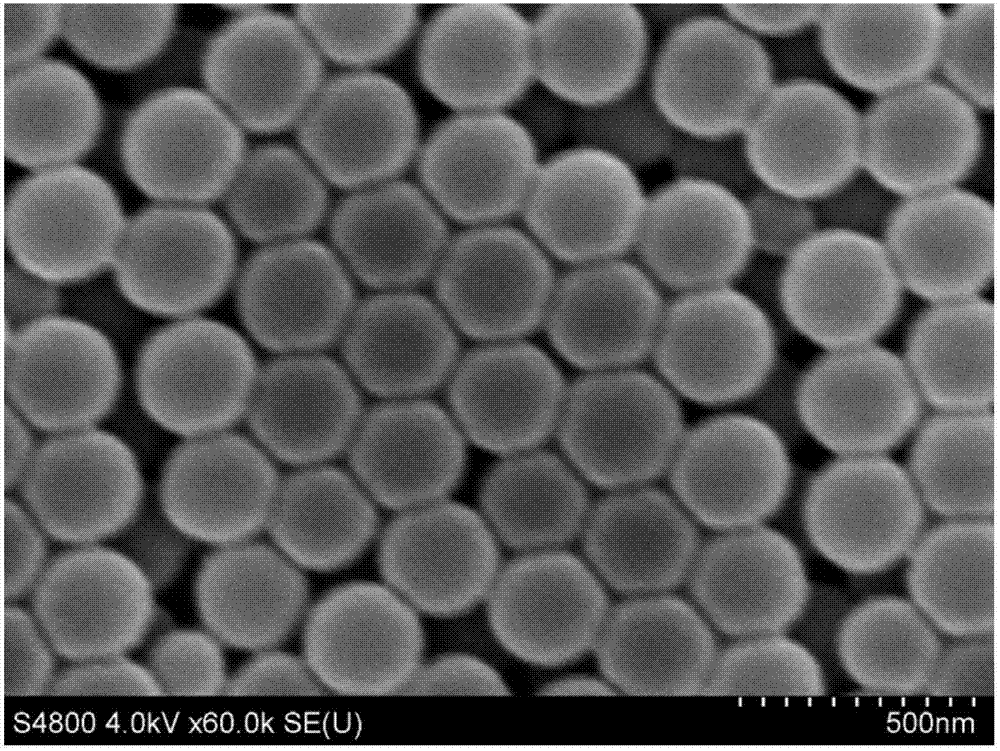

[0031] (1) Take 0.1g of polyvinylpyrrolidone (average relative molecular weight 45,000), mix 2ml of methyl methacrylate monomer, and 100mL of deionized water, and use ultrasonic intensity of 20kHz for 20min at room temperature. After the solution is clarified, add 0.05g ammonium persulfate, and then stir at 40°C with a stirring speed of 500rpm for 10 hours to obtain an emulsion containing polymethyl methacrylate microspheres. After suction filtration and drying, polymethylmethacrylate with an average particle size of about 230nm is obtained. Methyl acrylate microspheres, the scanning electron microscope (SEM) photograph of gained polymethyl methacrylate microspheres is as follows figure 1 Shown; As can be seen from the figure, the average particle diameter of polymethyl methacrylate nanoparticles is about 230nm, and the particle uniformity is good;

[0032] (2) Get the polymethyl methacrylate microsphere 4g obtained above, disperse in the deionized water of 46ml, ultrasonic 30...

Embodiment 2

[0035] (1) Take 0.1g of polyvinylpyrrolidone (average relative molecular weight: 45,000), mix 2ml of methyl methacrylate monomer, and 100mL of distilled water, and use ultrasonic intensity of 20kHz to sonicate for 20min at room temperature. After the solution is clarified, add 0.05g of persulfuric acid Ammonium, then at 40°C, stirring speed is 500rpm, stirring for 10h, you can get the emulsion containing polymethyl methacrylate microspheres, after suction filtration and drying, you can get polymethyl methacrylate with an average particle size of about 230nm Ester microspheres;

[0036] (2) Get the polymethyl methacrylate microsphere 4g obtained above, disperse in the deionized water of 46ml, ultrasonic 30min, make it fully disperse, obtain the polymethyl methacrylate microsphere colloid that concentration is 8wt% solution;

[0037](3) At 20°C, with a stirring speed of 500rpm, add 0.5g sodium lauryl sulfate to the polymethyl methacrylate microsphere colloid solution, after sti...

Embodiment 3

[0039] (1) Take 0.1g of polyvinylpyrrolidone (average relative molecular weight: 45000), 2ml of methyl methacrylate monomer, and 100mL of distilled water, mix them with ultrasonic intensity of 20kHz for 20min at room temperature, and then ultrasonically for 30min with ultrasonic intensity of 500kHz. After the solution is clarified, add 0.05g of ammonium persulfate, and then stir at 40°C for 10 hours at a stirring speed of 500rpm to obtain an emulsion containing polymethyl methacrylate microspheres, which is filtered and dried to obtain an average particle size of Polymethyl methacrylate microspheres of about 200nm;

[0040] (2) Get the polymethyl methacrylate microsphere 4g obtained above, disperse in the deionized water of 46ml, ultrasonic 30min, make it fully disperse, obtain the polymethyl methacrylate microsphere colloid that concentration is 8wt% solution;

[0041] (3) At 20°C, with a stirring speed of 500rpm, add 0.5g sodium lauryl sulfate to the colloidal solution of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com