Polyester hyperdispersant and preparation thereof as well as preparation method of isocyanate

A polyisocyanate and hyperdispersant technology, which is applied in the field of isocyanate preparation, can solve the problems of reduced production efficiency, difficulty in dispersing hydrochloride agglomerates, and unreachable problems, so as to improve the concentration and efficiency of salt formation, increase the concentration of salt formation and Effect, viscosity-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

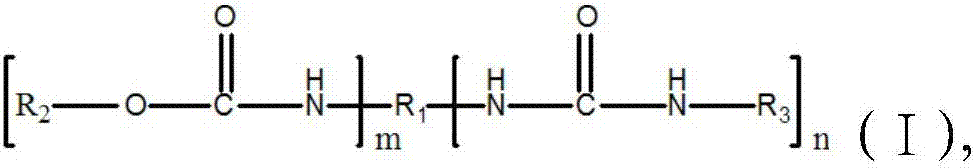

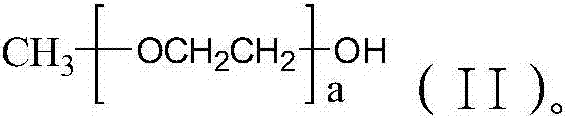

[0073] Add 42.8 g (0.1 mol, see formula (II) for the structural formula, wherein the value of a is 9) of single-terminated hydroxyl polyethylene oxide with a number average molecular weight of about 428 to 64.2 g of solvent butyl acetate, so that the solid content is 40 wt%, to obtain Single-ended hydroxyl polyethylene oxide solution.

[0074] Add 25gMDI (0.1mol, diphenylmethane diisocyanate) and 0.06g of catalyst dibutyltin dilaurate into a four-necked flask equipped with a stirrer, a thermometer and a condenser tube, and slowly add the prepared single Hydroxy-terminated polyethylene oxide solution. After the dropwise addition, the temperature was raised to 60°C.

[0075] When the -NCO content in the reaction system was 50 wt% of the initial -NCO content in the reaction system, 89.3 g of butyl acetate was added to reduce the viscosity of the system. The above mixed solution was added to 11.3g leucine (0.1mol), and the capping reaction was carried out at 80°C. When the resid...

Embodiment 2

[0080] 48.3g (0.08mol, see formula (II) for structural formula, wherein a value is 13) of single-terminal hydroxyl polyethylene oxide with a number average molecular weight of about 604 was added to 90g of solvent butyl acetate, so that the solid content was 35wt%, to obtain a single Hydroxy-terminated polyethylene oxide solution.

[0081] Add 37.7gXDI trimer (0.067mol, xylylene diisocyanate trimer) and catalyzer stannous octoate 0.08g in the four-neck flask equipped with stirrer, thermometer and condenser tube, keep constant temperature and slowly Add the prepared single-end hydroxyl polyethylene oxide solution dropwise. After the dropwise addition, the temperature was raised to 70°C.

[0082] When the -NCO content in the reaction system was 60 wt% of the initial -NCO content in the reaction system, 106.5 g of butyl acetate was added to reduce the viscosity of the system. And above-mentioned mixed solution is added in 19.8g phenylalanine (0.12mol), under 70 ℃, carry out cap...

Embodiment 3

[0087] 76.48g (0.08mol, see formula (II) for structural formula, wherein a value is 21) of single-terminated hydroxyl polyethylene oxide with a number average molecular weight of about 956 was added to 130g of solvent butyl acetate, so that the solid content was 37wt%, to obtain a single Hydroxy-terminated polyethylene oxide solution.

[0088] Add 35g of TDI trimer (0.067mol, toluene diisocyanate trimer) and 0.06g of catalyst stannous octoate into a four-necked flask equipped with a stirrer, thermometer and condenser, and slowly add the prepared Single-ended hydroxyl polyethylene oxide solution. After the dropwise addition, the temperature was raised to 80°C.

[0089] When the -NCO content of the reaction system was 60 wt% of the initial -NCO content of the reaction system, 69.3 g of butyl acetate was added to reduce the viscosity of the system. And the above mixed solution was added to 10.7g alanine (0.12mol), and the capping reaction was carried out at 60°C. When the resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com