Conformal radiotherapy tissue equivalent compensation glue and its preparation method and application

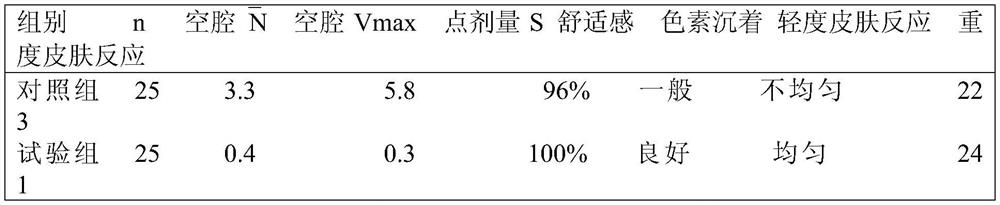

A tissue-equivalent and conformal technology, applied in the field of medical supplies, can solve the problems of easy formation of cavities, affecting the radiation effect of radiotherapy, etc., and achieve the effect of easy steps, reduction of secondary construction effects, and good fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

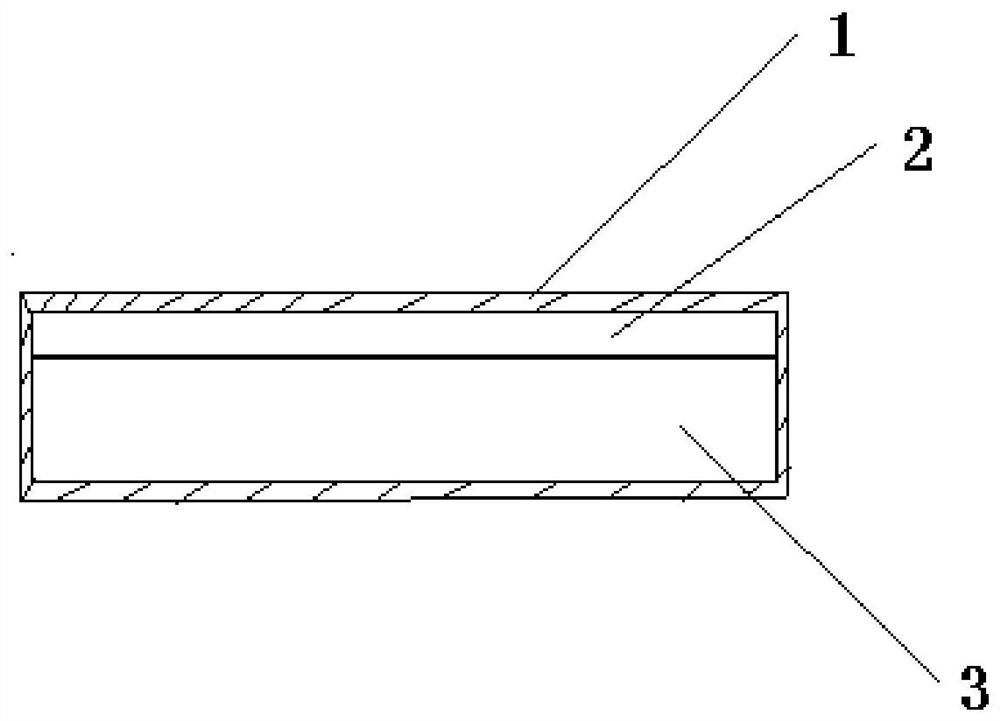

Embodiment 1

[0028] A conformal radiotherapy tissue equivalent compensation glue, comprising an uncured layer and a cured layer, the outer layers of the uncured layer and the cured layer are wrapped with a protective layer, the thickness of the cured layer is 3mm, and the thickness of the uncured layer is 0.1mm, The protective layer is made of medical PVC material, and the thickness of the protective layer is 0.2mm. The uncured layer and the cured layer are made of the same raw material components. The raw material components of the uncured layer and the cured layer are calculated in parts by weight: liquid 70 parts of rubber, 12 parts of epoxy soybean oil acrylate, 3 parts of ethoxy ethoxy ethyl acrylate, 0.2 parts of bis 2,6-difluoro-3-pyrrole phenyl titanocene.

[0029] A method for preparing conformal radiotherapy tissue equivalent compensation glue: comprising the following steps:

[0030] (1) First take 70 parts of liquid rubber by weight in the dark state, and add 3 parts of ethoxy ...

Embodiment 2

[0035] A conformal radiotherapy tissue equivalent compensation glue, including an uncured layer and a cured layer, the outer layer of the uncured layer and the cured layer is wrapped with a protective layer, the thickness of the cured layer is 10mm, and the thickness of the uncured layer is x-xmm , the protective layer is made of medical PVC material, the thickness of the protective layer is 0.5mm, the uncured layer and the cured layer are made of the same raw material components, and the raw material components of the uncured layer and the cured layer are calculated in parts by weight: 85 parts of liquid rubber, 10.5 parts of epoxy soybean oil acrylate, 4.5 parts of ethoxy ethoxy ethyl acrylate, 0.5 parts of bis-2,6-difluoro-3-pyrrole phenyl titanocene.

[0036] A method for preparing conformal radiotherapy tissue equivalent compensation glue: comprising the following steps:

[0037] (1) First take 85 parts of liquid rubber by weight in a dark state, and then add 4.5 parts of...

Embodiment 3

[0042] A conformal radiotherapy tissue equivalent compensation glue, including an uncured layer and a cured layer, the outer layer of the uncured layer and the cured layer is wrapped with a protective layer, the thickness of the cured layer is 15mm, and the thickness of the uncured layer is 20mm. The layer is made of medical PVC material, and the thickness of the protective layer is 0.2mm. The uncured layer and the cured layer are made of the same raw material components. The raw material components of the uncured layer and the cured layer are calculated in parts by weight: liquid rubber 90 parts, 8 parts of epoxy soybean oil acrylate, 5 parts of ethoxyethoxyethyl acrylate, 0.8 parts of bis-2,6-difluoro-3-pyrrole phenyl titanocene.

[0043] A method for preparing conformal radiotherapy tissue equivalent compensation glue: comprising the following steps:

[0044] (1) First take 90 parts of liquid rubber by weight in the dark state, and then add 5 parts of ethoxy ethoxy ethyl ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com