A kind of preparation method of polycrystalline photoluminescence zinc tungstate film

A technology of luminescence and zinc tungstate, applied in the direction of vacuum evaporation plating, metal material coating process, coating, etc., can solve the problems of difficult to realize large-area film preparation, complex process parameters, complex preparation process, etc., and achieve excellent Photoluminescence performance, process parameters are easy to control, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a polycrystalline photoluminescent zinc tungstate film, comprising the steps of:

[0041] (a) Preparation of tungsten oxide thin film layer:

[0042] (a1) Ultrasonic clean the quartz substrate with acetone, alcohol and deionized water successively, and use N 2 Blow dry, then dry the cleaned quartz substrate for 30min;

[0043] (a2) placing a metal tungsten target in a magnetron sputtering chamber, the purity of the metal tungsten target being 99.99%;

[0044] (a3) Put the clean quartz substrate in step (a1) into the magnetron sputtering chamber with a metal tungsten target, and evacuate to -4 Pa;

[0045] (a4) Introduce argon and oxygen into the above-mentioned magnetron sputtering chamber, adjust the volume flow ratio of argon and oxygen to 20:15, and the pressure of the magnetron sputtering chamber to 4Pa;

[0046] (a5) Turn on the magnetron sputtering power supply, adjust the sputtering power to 80W, start pre-sputtering for 3~10 minutes, an...

Embodiment 2

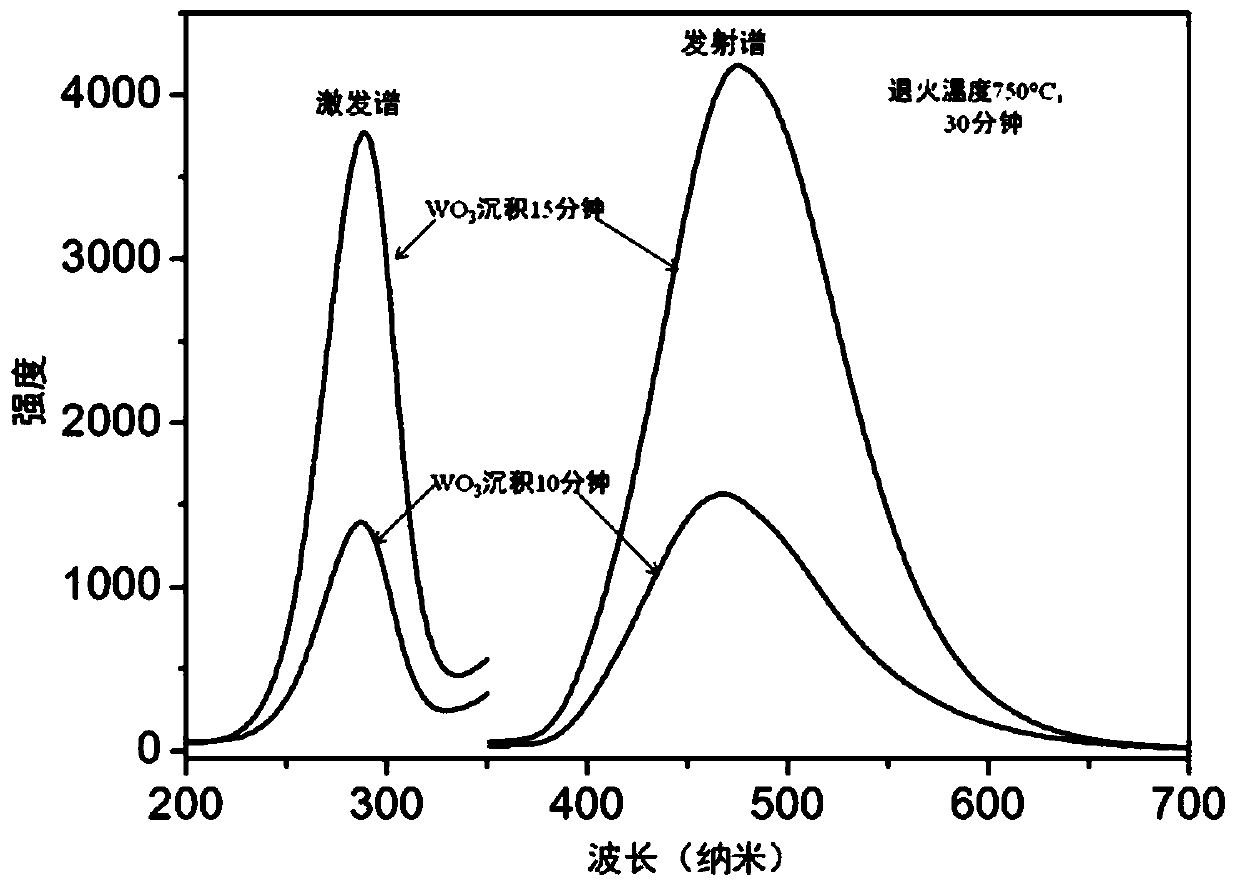

[0057] The experimental method is the same as in Example 1, other conditions remain unchanged, and the sputtering deposition time in step (a6) is set as a variable, which is 10min and 15min respectively, and the results are as follows figure 1 shown.

[0058] From figure 1 It can be seen that the annealing conditions for the fixed deposition ZnO layer are: the annealing temperature is 750°C, the holding time is 30min, and the heating rate is 3°C / min. 3 When the deposition time is 15min, under the same test conditions, the peak value of the emission spectrum of the obtained sample increases significantly when excited by light at about 285nm, which is WO 3 Deposit 2.5 times the sample for 10 min.

Embodiment 3

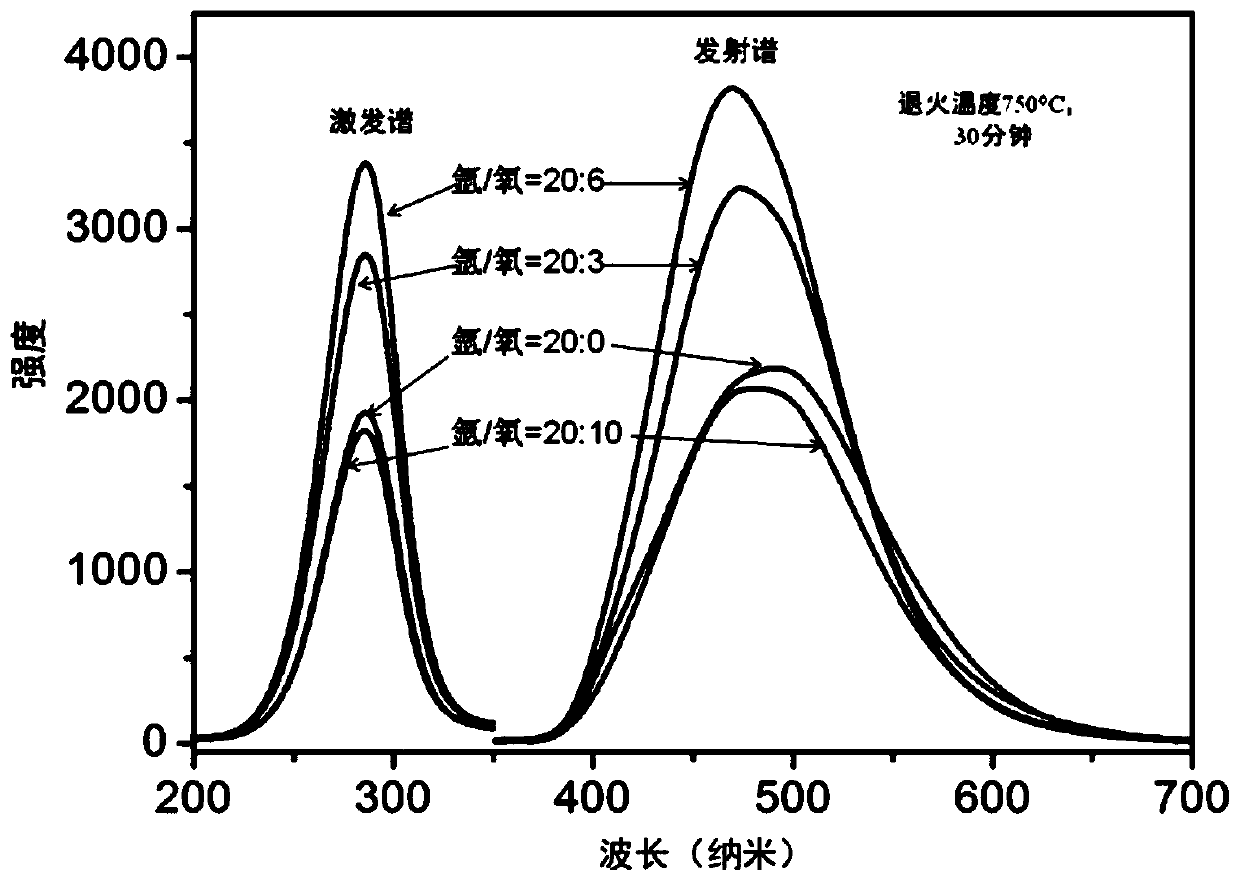

[0060] The experimental method is the same as that in Example 1, and other conditions remain unchanged. In step (b3), the volume flow ratio of argon and oxygen is adjusted to be variable, which are 20:0, 20:3, 20:6 and 20:10 respectively. The results are as follows figure 2 shown.

[0061] From figure 2 It can be seen that the fixed deposited WO 3 The annealing conditions are as follows: the annealing temperature is 750°C, the holding time is 30min, the heating rate is 3°C / min, when the volume flow ratio of argon and oxygen is 20:6, under the same test conditions, use The intensity of the emission spectrum of the obtained sample is the strongest when the light excitation is around 285nm, but when the volume flow ratio of argon and oxygen is 20:10, the luminous intensity of the obtained sample is significantly reduced, even lower than that of the sample obtained by oxygen-free sputtering The luminous intensity indicates that the oxygen content should not be too high during ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com