Composite filter tank for internal electrolysis and denitrification, and application thereof

A technology of denitrification and internal electrolysis, which is applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low synchronous denitrification and phosphorus removal efficiency, difficult backwashing, and operating costs Increase and other problems, to achieve the effect of improving biodegradability, good purification effect, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

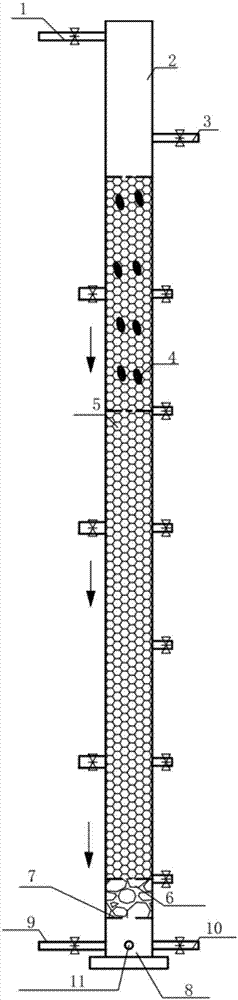

[0036] like figure 1As shown, an internal electrolytic denitrification composite filter, the filter includes a water distribution area 2, an iron-carbon doped area 4, a filler area 5, a supporting layer 6 and a water collection area 8 from top to bottom. The iron-carbon doped area 4, the filling area 5, the support layer 6 and the top of the water collection area 8 are all provided with a perforated water collection plate 7, and the bottom of the water collection area 8 is provided with a funnel-shaped slope with a slope of 5%; The upper part of the area is provided with a water inlet 1, and the lower part is provided with a backwash water outlet 3; the bottom of the catchment area is provided with a water outlet 10, a backwash water inlet 9 and a disturbance water inlet 11. The filler in the filler area 5 is ceramsite, and the filler in the iron-carbon doped area 4 is a mixture of iron-carbon and ceramsite. The filter tank is 1.2m high and 0.6m in diameter, wherein the thick...

Embodiment 2

[0047] In order to obtain the optimal position of iron-carbon doping, the present invention respectively doped 10% of iron-carbon in the upper, middle and lower parts of the device to obtain the optimal data. In Experimental Example 2, iron-carbon is doped in the first third of the device filler, in Experimental Example 3, iron-carbon is doped in the middle third of the device filler, and in Experimental Example 4, iron-carbon is doped in the rear third of the device filler.

[0048] As a comparison, in this embodiment, Experimental Example 1 is added, in which the matrix layer is not doped with iron carbon, and other experimental parameters are the same as those in Experimental Examples 2-4. Table 1 shows the iron-carbon doping conditions of experimental examples 1-4.

[0049] Table 1 Iron-carbon doping

[0050] Experimental serial number

1

2

3

4

stromal layer

none

10% Iron Carbon for the first third

Middle third 10% iron carbon

R...

Embodiment 3

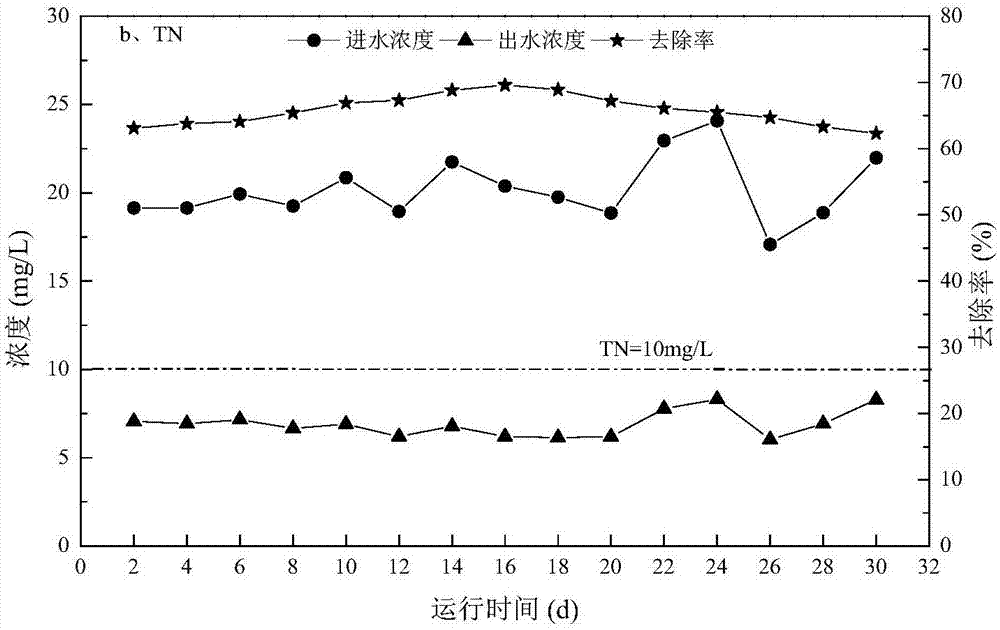

[0056] After the membrane was installed, the simulated tail water was introduced into the internal electrolytic denitrification composite filter device. The simulated tail water is shown in Table 1, and the C / N ratio was controlled at about 2. The HRT is set to 1h, the test period is 30d, and no carbon source is added. This embodiment is the same as Embodiment 1, and the water intake all adopts the water pump to lift and pressurize the water intake. After treatment, all effluent indicators are better than the special discharge limit in GB18918-2002 "Pollutant Discharge Standards for Urban Sewage Treatment Plants (2015 Draft for Comment)", that is, COD≤30mg / L, ammonia nitrogen≤1.5mg / L , TN≤10mg / L, TP≤0.3mg / L. After the above treatment, the water quality of its inlet and outlet water is shown in Table 3. Figure 2 to Figure 5 .

[0057] Table 3 Influent and effluent water quality and removal rate

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com