Sodium ion battery positive electrode material, preparation method thereof and sodium ion battery

A sodium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low conductivity, achieve uniform phase, high purity, and improve electron/ion diffusion kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 0.04mol sodium acetate, 0.005mol ferrous oxalate, 0.005mol manganese acetate, 0.01mol ammonium metavanadate and 0.03mol ammonium dihydrogen phosphate and dissolve them in 150mL deionized water, and add 60mL tetraethylene glycol and ethylene glycol (volume ratio 1 : 1) the mixed solution was stirred at room temperature for 1 h to obtain a mixed solution. Then the obtained mixed solution was transferred to a reaction kettle, reacted at 180° C. for 10 h to obtain a viscous colloid, and then freeze-dried the viscous colloid to obtain a precursor powder. Then the precursor powder was calcined at 750 °C for 8 h in an argon atmosphere to obtain Na 4 Fe 0.5 mn 0.5 V(PO 4 ) 3 Cathode material for sodium ion batteries.

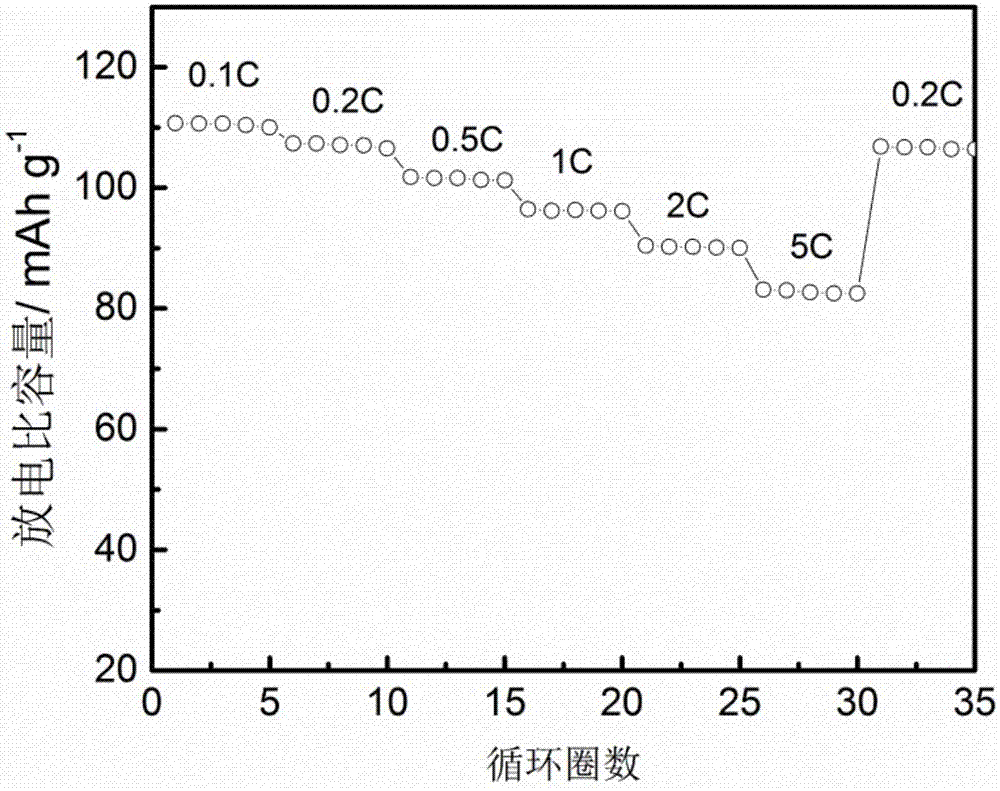

[0044] The produced Na 4 Fe 0.5 mn 0.5 V(PO 4 ) 3 The morphology (SEM) of the positive electrode material is shown in figure 1 ,Depend on figure 1 It can be seen that it is an irregular sheet structure. figure 2 for the resulting Na 4 Fe 0.5 ...

Embodiment 2

[0046] Take 0.04mol sodium acetate, 0.005mol ferrous oxalate, 0.005mol manganese acetate, 0.01mol ammonium metavanadate and 0.03mol ammonium dihydrogen phosphate in 100mL deionized water, and add 60mL tetraethylene glycol and ethylene glycol (volume ratio 1: 1) The mixed solution was stirred at room temperature for 1 h to obtain a mixed solution. Then the obtained mixed solution was transferred to a reaction kettle, reacted at 180° C. for 10 h to obtain a viscous colloid, and then freeze-dried the viscous colloid to obtain a precursor powder. The precursor powder was then calcined at 750 °C for 8 h under an argon atmosphere to obtain Na 4 Fe 0.5 mn 0.5 V(PO 4 ) 3 Cathode materials for sodium ion batteries. It is a trigonal crystal system, the space group is R-3c, and the phase is uniform.

[0047] Na prepared by this embodiment 4 Fe 0.5 mn 0.5 V(PO 4 ) 3 The positive electrode material of the sodium ion battery and the sodium sheet are assembled into a button batter...

Embodiment 3

[0049] Take 0.04mol sodium acetate, 0.005mol ferrous oxalate, 0.005mol manganese acetate, 0.01mol ammonium metavanadate and 0.03mol ammonium dihydrogen phosphate in 200mL deionized water, and add 60mL tetraethylene glycol and ethylene glycol (volume ratio 1: 1) The mixed solution was stirred at room temperature for 1 h to obtain a mixed solution. Then the obtained mixed solution was transferred to a reaction kettle, and reacted at 180° C. for 10 h to obtain a viscous colloid, and then the viscous colloid was freeze-dried to obtain a precursor powder. The precursor powder was then calcined at 750 °C for 8 h under an argon atmosphere to obtain Na 4 Fe 0.5 mn 0.5 V(PO 4 ) 3 Cathode materials for sodium ion batteries. It is a trigonal crystal system, the space group is R-3c, and the phase is uniform.

[0050] Na prepared by this embodiment 4 Fe 0.5 mn 0.5 V(PO 4 ) 3 The positive electrode material of the sodium ion battery and the sodium sheet are assembled into a butto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com