Ultraviolet curing colored coating for glass color mirror and application thereof

A coloring coating and ultraviolet light technology, applied in the direction of polyester coating, epoxy resin coating, polyurea/polyurethane coating, etc., can solve the problems of long drying time of coating, large VOC emission, unfavorable human health, etc., and achieve smooth appearance, Good plating performance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under dark conditions, based on the total mass of the final coating, 45wt% urethane acrylate (B-151), 22wt% hydroxypropyl methacrylate, 20wt% hydroxyethyl methacrylate and 5wt% BASF Mix TPO photoinitiators, heat up to 55°C, and stir evenly. Then add 1.8wt% leveling agent (BYK3510), 1wt% dispersant (BYK163), 0.2wt% defoamer (BYK055), and 5% red toner, stir well, disperse at high speed, grind until fine The degree is less than 1um, filtered to obtain UV-curable red paint.

Embodiment 2

[0029] Under dark conditions, based on the total mass of the final coating, 30wt% novolac epoxy acrylate (EAM-2160W), 30wt% polyester acrylate (W2500b), 10wt% hydroxypropyl acrylate, 18wt% Hydroxyethyl methacrylate, 2wt% BASF TPO and 3wt% Ciba 1173 photoinitiator were mixed, heated to 60°C, and stirred evenly. Then add 1.5wt% leveling agent (BYK333), 1.2wt% dispersant (BYK2009), 0.3wt% defoamer (BYK085), and 4% yellow toner, stir well, disperse at high speed, and grind until The fineness is less than 1um, filtered to obtain UV-curable yellow paint.

Embodiment 3

[0031]Under dark conditions, based on the total mass of the final coating, 16wt% polyurethane acrylate (PP2208), 25wt% polyester acrylate (B-581L), 20wt% hydroxypropyl methacrylate, 20wt% Hydroxyethyl methacrylate, 3wt% BASFPO and 3wt% Ciba 1173 photoinitiator were mixed, heated to 60°C, and stirred evenly. Then add 1wt% leveling agent (BYK333), 1.8wt% dispersant (BYK2009), 0.2wt% defoamer (BYK085), and 10% purple toner, stir well, disperse at high speed, grind until fine The degree is less than 1um, filtered to obtain UV-curable purple paint.

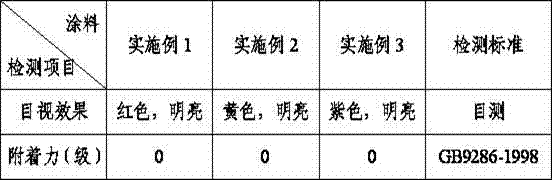

[0032] 2. Fabrication and performance characterization of colored glass mirrors

[0033] 2.1 Coloring

[0034] The coatings of Examples 1-3 are respectively sprayed on one side of the cleaned glass by a flow coating machine, the thickness is controlled at about 50 μm, inverted treatment, infrared leveling at 60°C, and then three wavelengths of 260-340nm and power of A 16.8KW mercury lamp is used as a radiation source for UV curing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com