Preparation method for bimetallic composite internal anticorrosive pipe

A bimetallic pipe and internal anti-corrosion technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as bulges or leaks, severe deformation of lined pipes, and reduced product quality, etc., and achieve strong application value , Excellent product performance, and the effect of reducing the waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

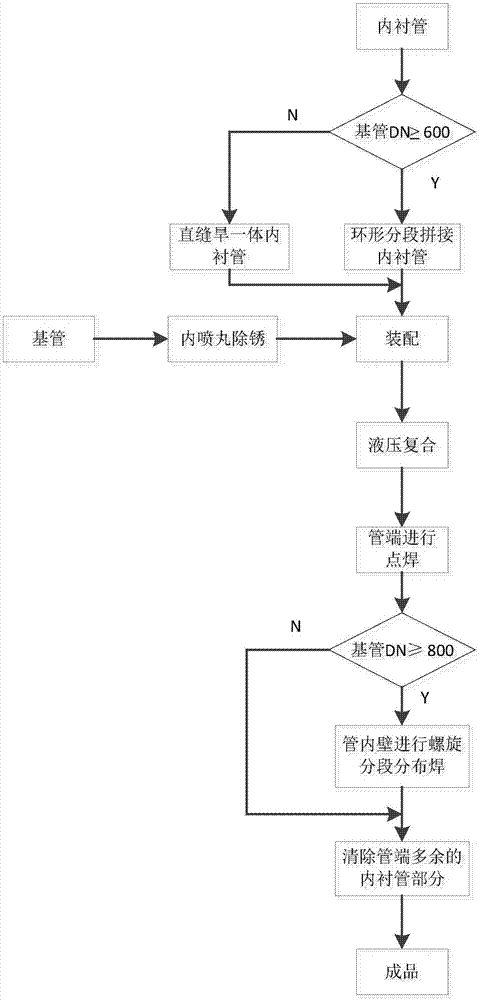

[0034] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0035] The invention discloses a method for preparing a bimetallic composite inner anti-corrosion pipe. The bimetallic pipe body is composed of a liner pipe and a base pipe. For alloy pipe or metal pipe, in the bimetallic pipe forming process, different composite methods (processes) and lining pipe forming processes are used for different base pipe diameters, so that the lining pipe is combined with the inner wall of the base pipe.

[0036] The lining pipe forming process is:

[0037] When the DN of the base pipe is less than 600mm, the lining pipe shall be formed by straight seam welding;

[0038] When the DN of the base pipe is ≥600mm, the lining pipe shall be spliced with circular seam.

[0039] Described composite method is:

[0040] When the DN of the base pipe is less than 800mm, the hydraulic composite method is adopted;

[0041] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com