Fan-out wafer-level chip packaging structure and method

A wafer-level chip and packaging structure technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of difficult preparation and high production cost of fan-out wafer-level chip packaging structure, and achieve improved heat dissipation performance, The preparation difficulty is small and the effect of improving the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

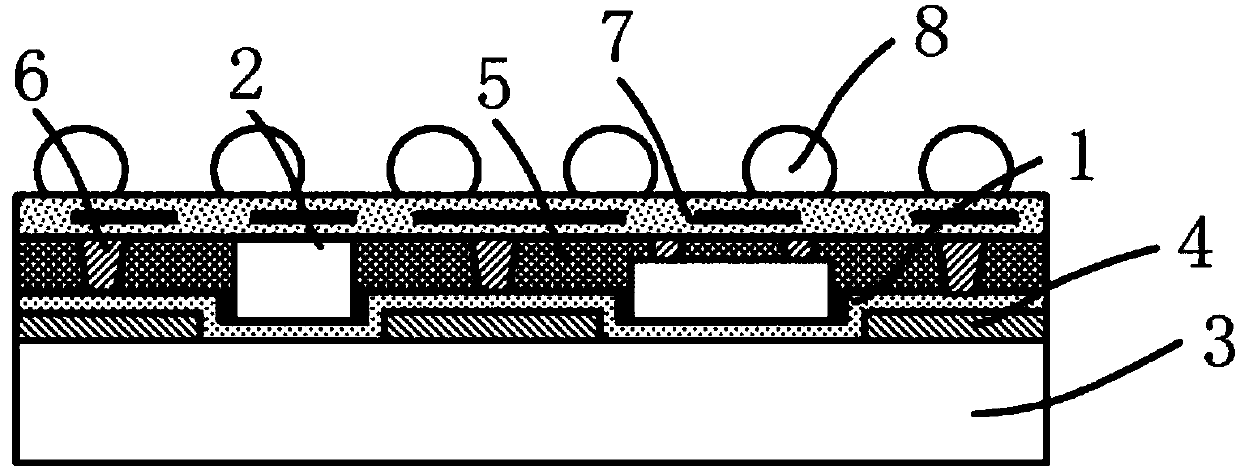

[0032] This embodiment provides a fan-out wafer level chip packaging structure, such as figure 1 As shown, it includes: conductive layer 1, a groove for setting chip 2 is formed on conductive layer 1; conductive layer 1 is arranged on substrate 3; insulating layer 4 is arranged between conductive layer 1 and substrate 3 for filling The gap between the conductive layer 1 and the substrate 3; the package 5 is arranged on the upper surface of the conductive layer 1; the chip 2 is packaged in the package 5, and the pad of the chip 2 is exposed outside the package 5; the conductive column 6 is set In the package body 5 , one end is coupled to the conductive layer 1 , and the other end is exposed outside the package body 5 ; the conductive post 6 is connected to the ground wire. In a specific embodiment, the depth of the groove is smaller than the thickness of the chip 2, and the conductive layer 1 is aluminum, copper, aluminum alloy or copper alloy layer. Preferably, the thickness ...

Embodiment 2

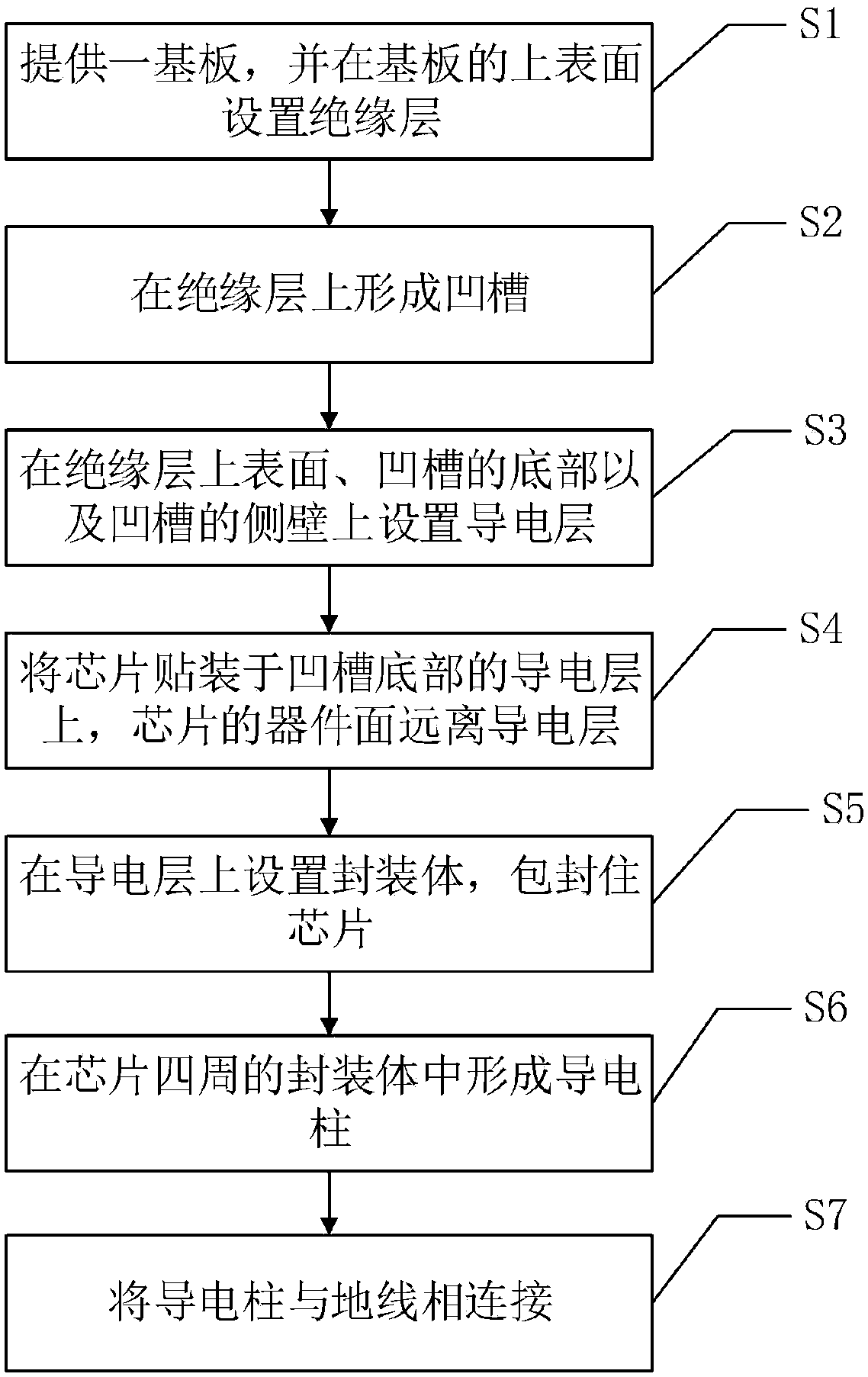

[0040] This embodiment provides a fan-out wafer level chip packaging method, such as figure 2 As shown, including the following steps:

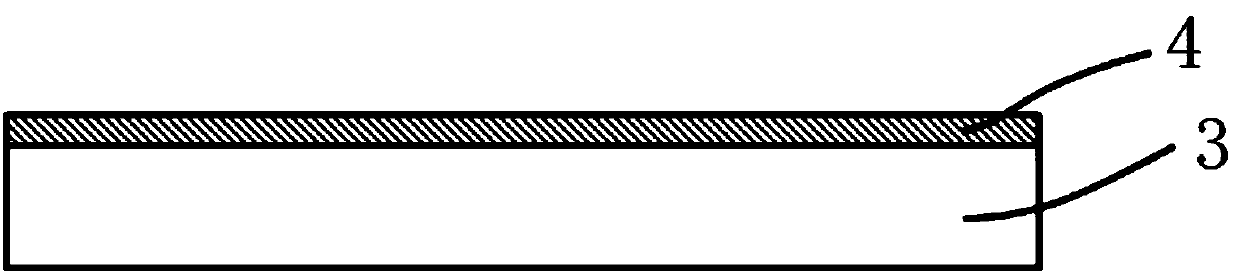

[0041] Step S1: providing a substrate, and disposing an insulating layer on the upper surface of the substrate. Such as image 3 As shown, in this embodiment, the insulating layer 4 may be provided by spray coating or spin coating. In a specific embodiment, the material of the substrate 3 is a material with good thermal conductivity such as silicon, silicon carbide, thermally conductive ceramics or metal, and the insulating layer 4 is a photosensitive material layer prepared by photosensitive polyimide or other photosensitive resins. Of course, it can also be a non-photosensitive material layer. Preferably, the thickness of the insulating layer 4 is 2-20um.

[0042] Step S2: forming grooves on the insulating layer. Such as Figure 4 As mentioned above, in a specific embodiment, when the insulating layer 4 is a photosensitive material la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com