Multi-duct transition metal phosphide carbon nanotube composite material and preparation method and application based on small molecule regulation

A technology of carbon nanotubes and transition metals, applied in phosphating, electrolysis, electrodes, etc., can solve the problems of high cost of hydrogen production catalysts for electrolysis of water, restrictions on large-scale use, and lack of platinum resources, etc., to achieve easy large-scale production , controllable size and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

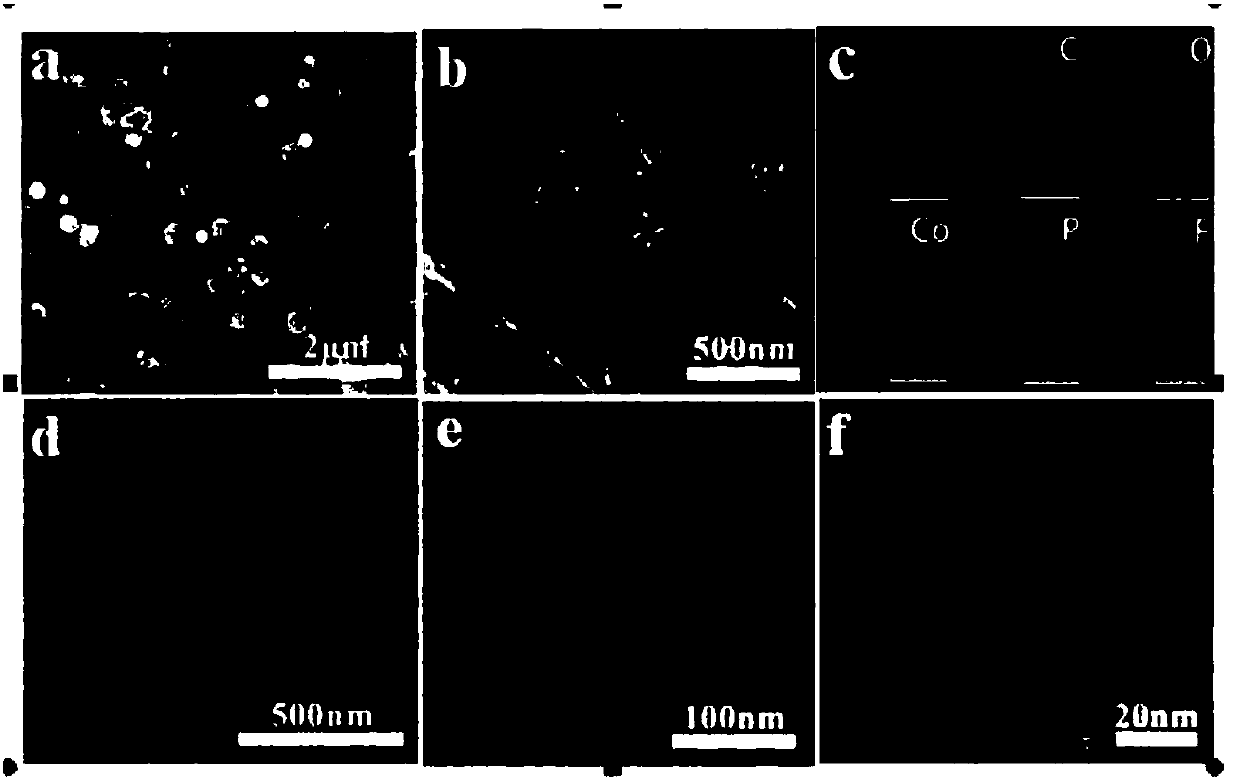

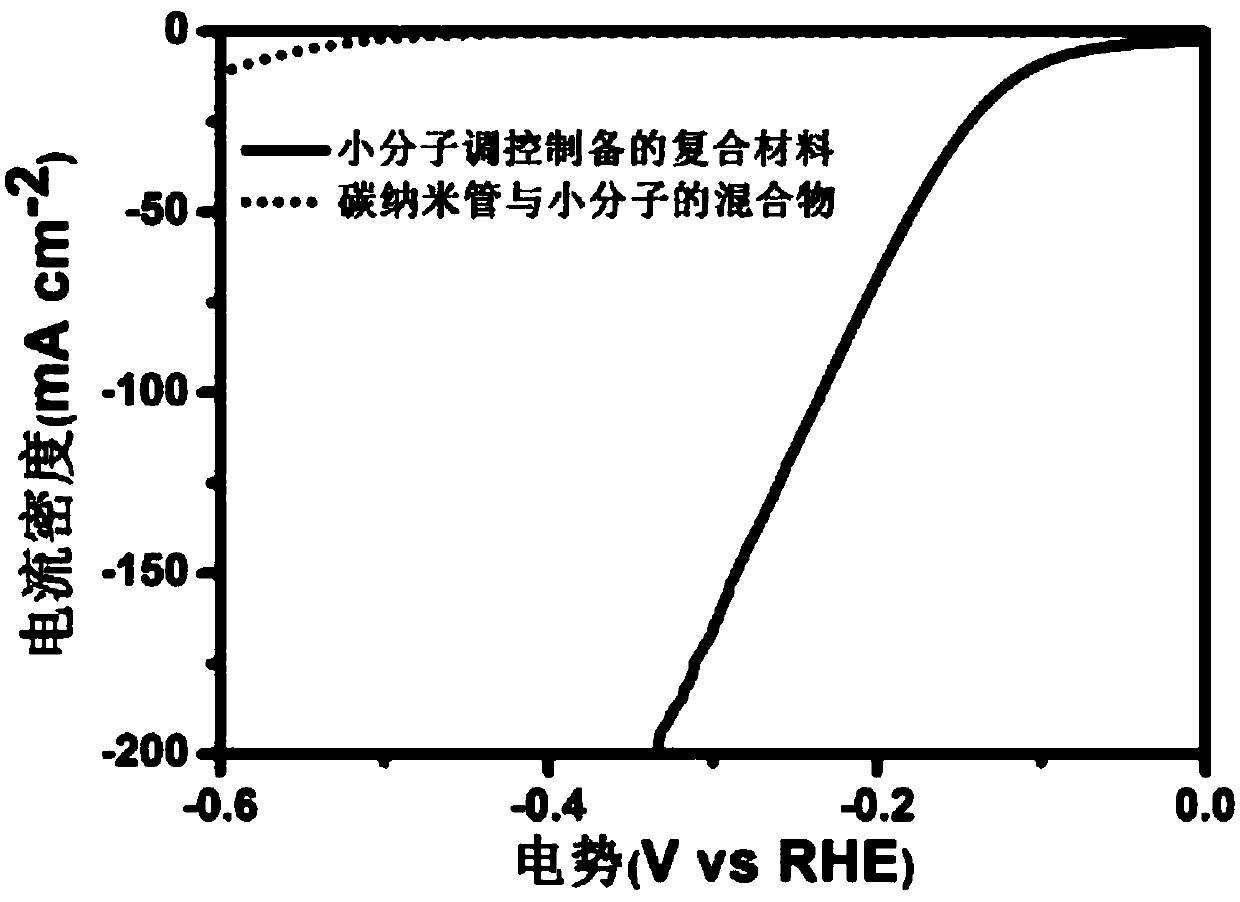

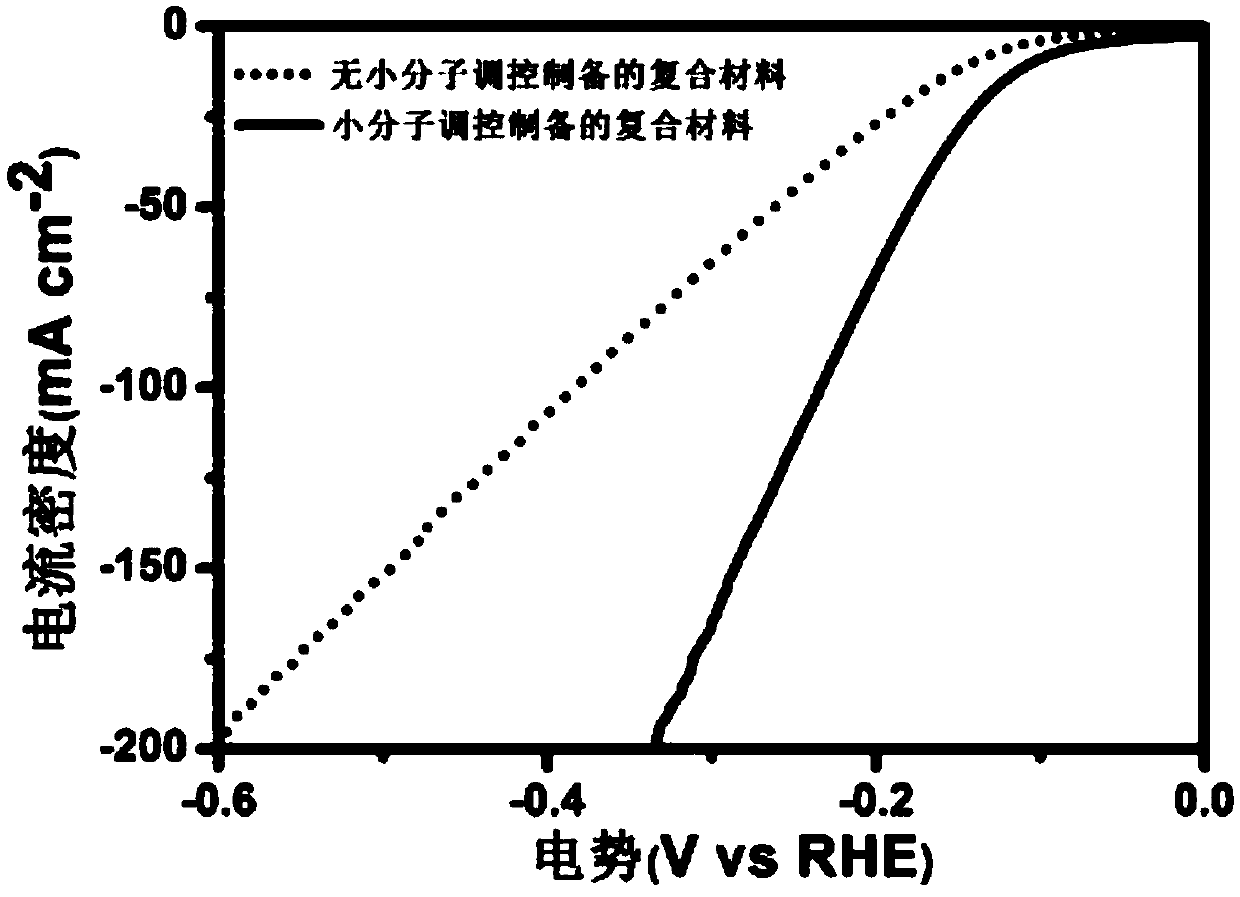

[0041] Example 1: Cobalt phosphide / carbon nanotube composite material (CoP / CNTs-Ph 3 P)

[0042] (1) Electrode pretreatment: Take a glassy carbon electrode (Shanghai Chenhua, CHI104, 3mm in diameter), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 30s in sequence;

[0043] (2) Preparation of a glassy carbon electrode modified by a mixture of carbon nanotubes and triphenylphosphine: Add the mixture of arrayed carbon nanotubes (2 mg) and triphenylphosphine (2 mg) to a mixture of ethanol and water at a volume ratio of 1:1 ( 1mL), ultrasonically at 40KHz for 2h to form a suspension, which was dropped onto the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform thin mixture of carbon nanotubes and triphenylphosphine. layer (the thin layer is about 40 μg of carbon nanotubes), to obtain a glassy carbon electrode modified by a mixture of carbon nanotubes and triphenylphosphine;

[0044] (3) Preparation of el...

Embodiment 2

[0047] Example 2: Preparation of Porous Cobalt Phosphide / Carbon Nanotube Composite (CoP / CNTs-PF) by Small Molecule Tris(4-fluorophenyl)phosphine

[0048] (1) Electrode pretreatment: Take a glassy carbon electrode (Shanghai Chenhua, CHI104, 3mm in diameter), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 30s in sequence;

[0049] (2) Preparation of glassy carbon electrode modified by mixture of carbon nanotubes and tris(4-fluorophenyl)phosphine: add the mixture of arrayed carbon nanotubes (2mg) and tris(4-fluorophenyl)phosphine (2mg) to ethanol and In the mixed solution (1mL) with a water volume ratio of 1:1, a suspension was formed by ultrasonication at 40KHz for 2 hours, and the suspension was added dropwise to the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform A thin layer of carbon nanotubes and tris(4-fluorophenyl)phosphine mixture (the thin layer is about 40 μg of carbon nanotubes), to obta...

Embodiment 3

[0054] Example 3: Preparation of porous phosphide / carbon nanotube composites (CoNiP / CNTs-Ph 3 PBH 3 )

[0055] (1) Electrode pretreatment: Take a glassy carbon electrode (Shanghai Chenhua, CHI104, 3mm in diameter), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 30s in sequence;

[0056] (2) Prepare a glassy carbon electrode modified by a mixture of carbon nanotubes and triphenylphosphine borane: add a mixture of arrayed carbon nanotubes (2 mg) and triphenylphosphine borane (1 mg) to ethanol and water at a volume ratio of 1:1 In the mixed solution (1mL), 40KHz ultrasonic 2h forms suspension liquid, this suspension liquid is added dropwise on the surface of the glassy carbon electrode pretreated by step (1), and naturally dries to form uniform carbon nanotube and triphenyl A thin layer of a mixture of base phosphine borane (the thin layer is about 40 μg of carbon nanotubes), to obtain a glassy carbon electrode modified by a mixture of carbon nanotu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com